Efficient cutting device for foam plastic board

A foam plastic board and cutting device technology, applied in metal processing, etc., can solve the problems of easy accidents, high labor costs, and low safety, and achieve high work efficiency, low labor costs, and less accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

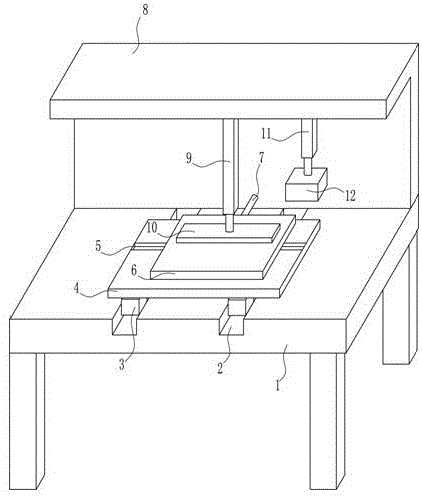

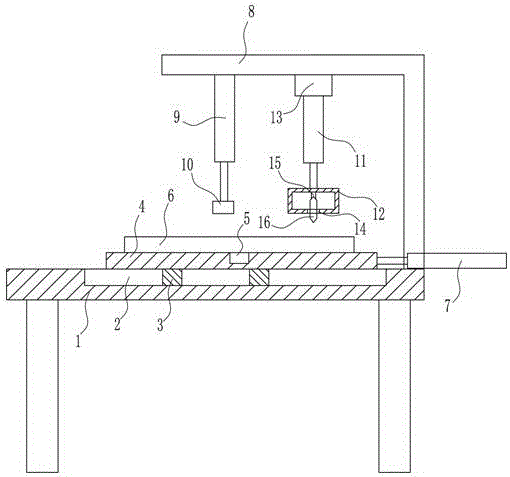

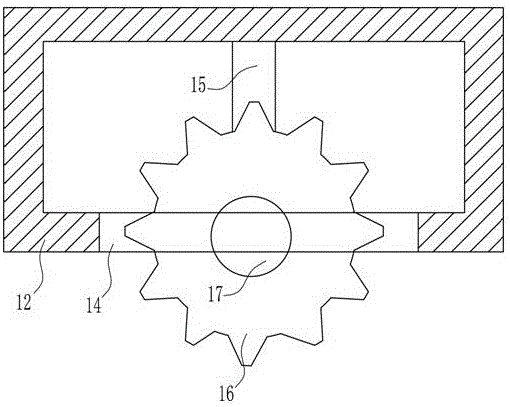

[0029] A high-efficiency cutting device for foam plastic boards, such as Figure 1-5 As shown, it includes a table 1, a slider 3, a placing plate 4, a first cylinder 7, a 7-type plate 8, a second cylinder 9, a pressure plate 10, a third cylinder 11, a box 12, a moving device 13, and a support rod 15. , the cutter 16 and the first motor 17, there is a vertical chute 2 on the table 1, a sliding block 3 is slidably connected in the chute 2, a placing plate 4 is welded on the top of the sliding block 3, and the placing plate 4 is horizontally opened. There is a groove 5, a 7-type plate 8 is welded on the back side of the table 1, the bottom and rear side of the 7-type plate 8 are connected with a first cylinder 7 by means of bolts, and the telescopic rod of the first cylinder 7 passes through the front side of the 7-type plate 8 And connected with the placing plate 4, the front side of the inner top of the 7-type plate 8 is connected with a second cylinder 9 by means of bolt conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com