Special printing plate-making paper for computer

A printing and computer technology, which is applied in the field of computer-specific printing plate-making paper, can solve the problems of poor ink absorption effect and easy oxidation, and achieve the effect of clear printing, not easy to turn yellow, and smooth and delicate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

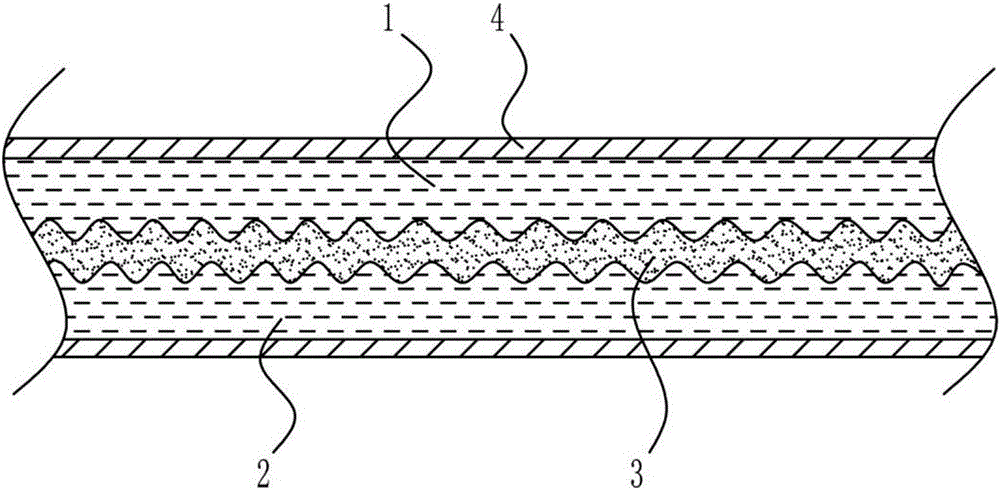

[0026] A special printing paper for computer, such as figure 1 As shown, it includes a first paper layer 1, a second paper layer 2, a nanoscale activated carbon layer 3 and a coating 4, and a nanoscale activated carbon layer 3 is sandwiched between the first paper layer 1 and the second paper layer 2, and the first The outer layers of the paper layer 1 and the second paper layer 2 are coated with a coating 4 .

[0027] The formula of coating 4 calculated according to the mass fraction is: ethyl acetate 6.5-6.9%, sodium acetate 5.4-6%, sodium stearate 10-11%, calcium sulfate 15.4-15.5%, 2-camphorone 15.1-15.9% , ferrous hydroxide 8-9.5%, modified starch 3.5-4%, and the rest is water.

[0028] The inner surface layers of the first paper layer 1 and the second paper layer 2 are wavy.

[0029] The thickness ratio of the first paper layer 1 to the second paper layer 2 is 1:1.

[0030] The thickness ratio of the first paper layer 1 to the nanoscale activated carbon layer 3 is 1:0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com