Coating fluid for inkjet high-gloss waterproof printing paper, and printing paper and preparation method thereof

A technology for coating liquid and photographic paper, applied in coating, polyurea/polyurethane coatings, etc., can solve the problems of damp discoloration, poor ink absorption, waterproof and weather resistance of photographic paper, complicated batching process, etc., and achieve good adhesion. The effect of knot and water resistance, high internal structure strength, high color reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 cationic aqueous polyurethane emulsion

[0051] Firstly, toluene diisocyanate (TDI), polytetrahydrofuran (PTMG), and N-methyldiethanolamine (MDEA) were dehydrated in vacuum at 120°C and 4kPa for 2 hours, and sealed and stored for later use. Other raw materials were used directly.

[0052] (1). Add 20-30 parts by weight of toluene diisocyanate (TDI), 5-10 parts by weight of polytetrahydrofuran (PTMG) and 1- 3 parts by weight of polyether polyol (PPG, molecular weight: 2000), stirred evenly and heated to 90°C for 2-3h of polymerization reaction;

[0053] (2). Cool down to 70°C, then slowly add the hydrophilic chain extender N-methyldiethanolamine (MDEA) dropwise in an amount of 2-5 parts by weight, and react at 80°C for 2-4 hours to obtain prepolymerized polyurethane body; use di-n-butylamine titration to measure isocyanate (-NCO) content, and after the -NCO content reaches the theoretical value, cool down to about 45°C;

[0054] (3). In...

Embodiment 2

[0060] Embodiment 2 Preparation of Inkjet High Gloss Waterproof Photo Paper Coating Solution

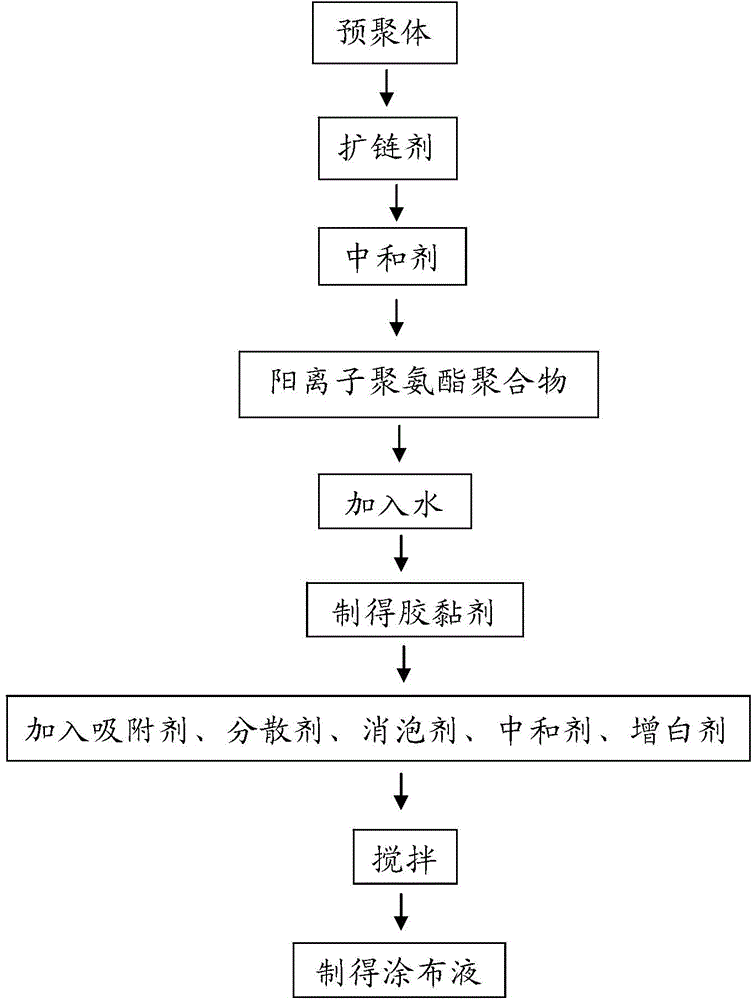

[0061] Such as figure 1 As shown, the schematic flow chart of the preparation of inkjet high-gloss waterproof coating solution,

[0062] 1) at first prepare cationic aqueous polyurethane emulsion, specifically adopt the preparation method of embodiment 1;

[0063] 2) Prepare the coating solution, the specific steps are as follows:

[0064] Add 10-40 parts by weight of toner adsorbent to 140-200 parts by weight of distilled water, stir evenly, and then add 30-55 parts by weight of cationic water-based polyurethane emulsion (ie adhesive), the cationic water-based polyurethane The emulsion adopts the emulsion prepared in Example 1. After stirring evenly, add 0.05-0.15 parts by weight of dispersant and stir. During the stirring process, add 0.05-0.15 parts by weight of whitening agent, 2-5 parts by weight of defoamer, 1 - 3 parts by weight of a neutralizing agent, stirred evenly, and ...

Embodiment 3

[0067] The preparation of embodiment 3 ink-jet high waterproof photographic paper

[0068] Use the double-sided coated paper base as the substrate, coat the coating liquid prepared in Example 2 on the substrate, and form an ink-absorbing coating after drying, that is, to obtain an inkjet high-gloss waterproof photographic paper. Further, as a preferred option, in The other side of the double-sided film-coated paper base is coated with the cationic water-based polyurethane emulsion prepared in Example 1 for primer coating, which improves the adhesion between the primer and the substrate, makes the primer and the substrate more firmly combined, and effectively prevents the prepared photographic paper from It can prevent deviation during printing and play an anti-skid role.

[0069] The photographic paper prepared in this example has a high internal structural strength of the coating, good adhesion to the substrate, and good scratch resistance on the coating printing surface; it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com