Six-face shaping mechanism of vacuum packaging machine

A vacuum packaging machine and outer frame technology, which is applied in the direction of packaging, pressurized/gasification packaging, etc., can solve the problems of large volume, not compact space, affecting the shaping and sealing work, etc., to achieve compact size, improve shaping and sealing work, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

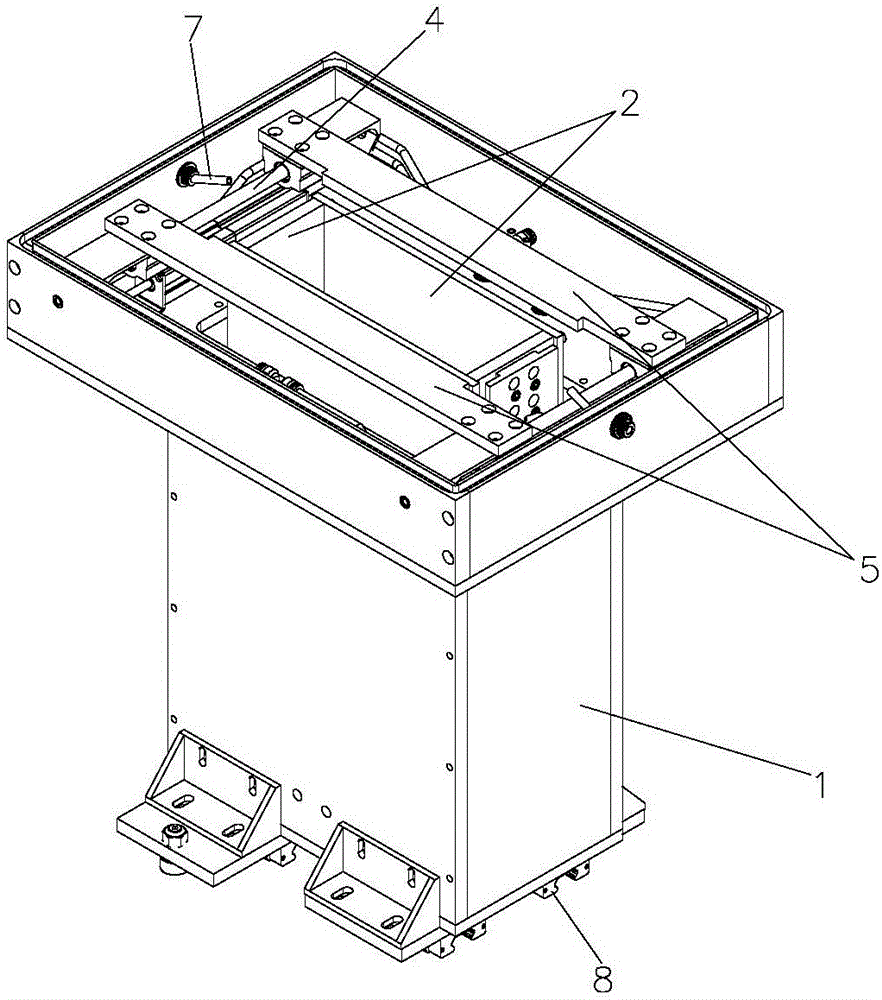

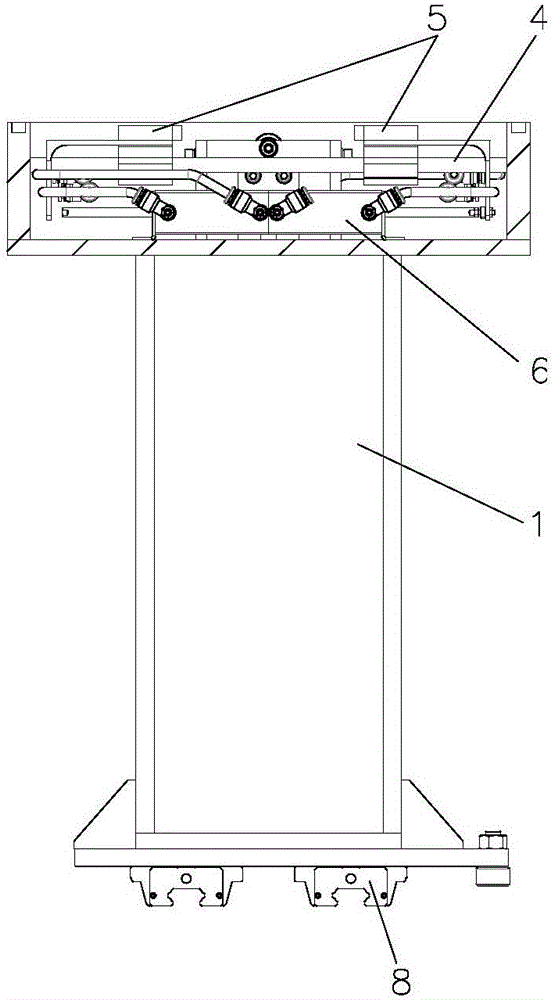

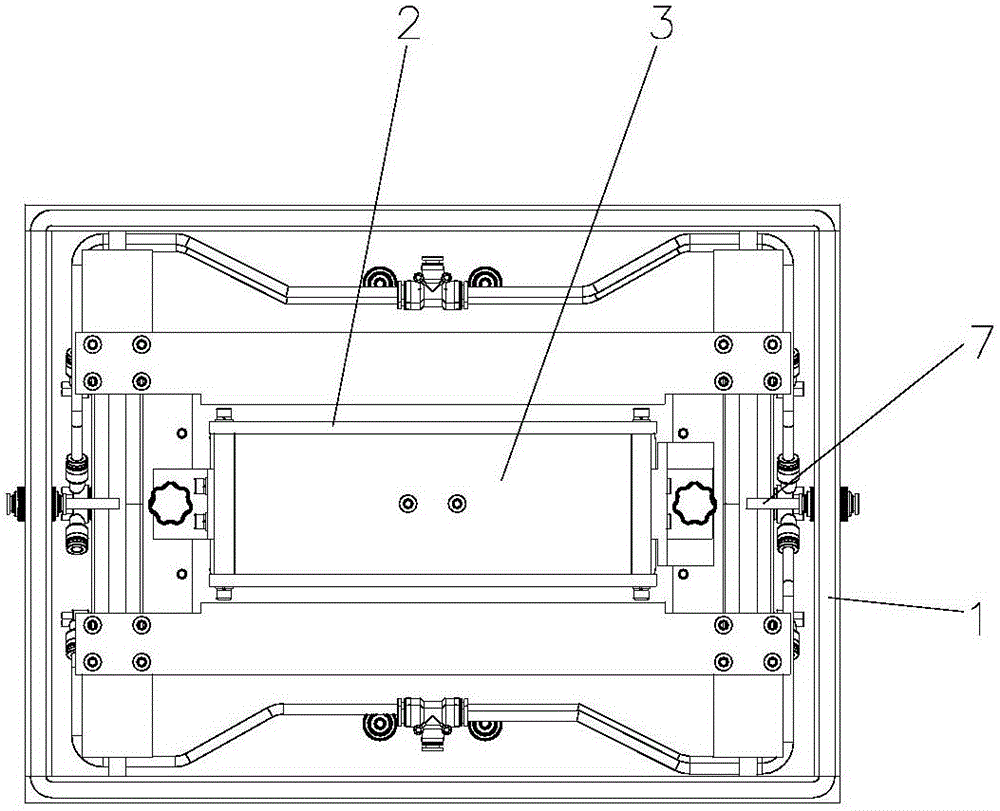

[0015] Such as Figures 1 to 3 As shown in one of them, the present invention comprises the outer frame 1 that the top is open, is provided with in the outer frame 1 and is surrounded by four side plates 2 and a movable bottom plate 3, and the movable bottom plate 3 is arranged in the outer frame 1 The lifting cylinder is driven to do the lifting movement; the opening of the outer frame 1 is provided with a clamping unit, which includes two guide rods 4 respectively arranged on both sides of the plastic cavity, and the two guide rods 4 are slidingly connected. There are two clamping plates 5, and a pair of piston rod cylinders 6 are respectively arranged in the outer frame 1 and below the two ends of the two clamping plates 5, and the two piston rods of the double piston rod cylinder 6 are connected with the two clamping plates 5 respectively. The ends of the two clamping plates 5 are connected and driven to move synchronously; the opposite inner walls of the outer frame 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com