Wood bundling steel wire roller

A steel wire roller and wood technology, applied in the field of ship transportation, can solve the problems of labor-consuming and time-consuming manual unwinding, loose overall structure, and large space occupation, and achieve the effects of time-saving operation, flexible use, and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

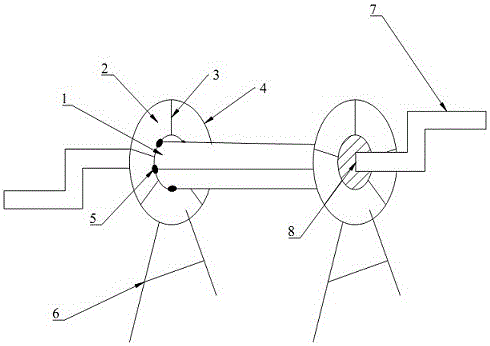

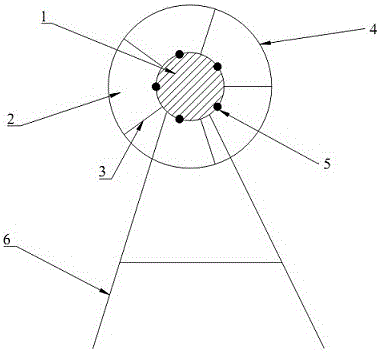

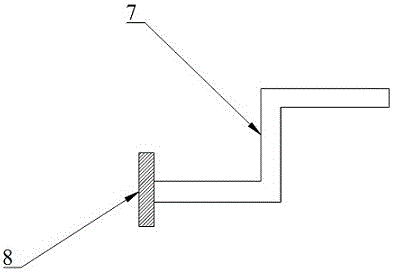

[0018] Such as figure 1 , 2 , shown in 3: a wood binding steel wire roller, its structure includes: main steel plate 1, disc body 2, steel bar 3, outer ring 4, shaft eye 5, bracket 6, crank handle 7, bearing 8; disc body 2 is a disc-shaped hollow body, the center point of the disc body 2 is provided with a main steel plate 1, the main steel plate 1 is connected to the outer ring of the disc body 2 through a steel bar 3, and the steel bar 3 is welded to the main steel plate 1 and the outer ring 4 are fixed, the periphery of the main steel plate 1 is provided with a shaft eye 5, the bracket 6 is installed on the outer side of the main steel plate 1 through a bearing, and the handle 7 is connected to the outer side of the main steel plate 1 through a bearing 8; the circle The disc body 2 is arranged in two combinations, and the left and right ends of the steel bar 3 in the middle of the two disc bodies 2 are fixedly connected to each other with the shaft eye 5 through screws; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com