Flame-retardant silicone rubber heat-shrinkable sleeve and preparation method thereof

A heat-shrinkable sleeve and silicone rubber technology, used in tubular articles, other household appliances, applications, etc., can solve the problems of small shrinkage ratio, unstable shrinkage performance, poor flame retardancy, etc., and achieve a large shrinkage ratio and stable shrinkage performance. , good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

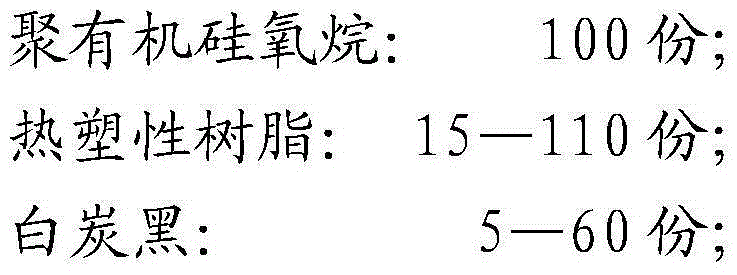

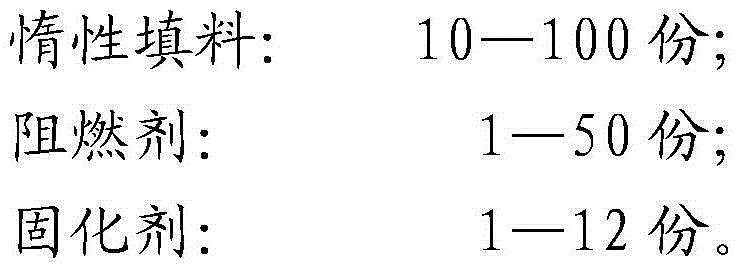

[0030] The invention provides a flame-retardant silicone rubber heat-shrinkable sleeve and a preparation method thereof. The constituent materials of the flame-retardant silicone rubber heat-shrinkable sleeve include: polyorganosiloxane, thermoplastic resin, white carbon black, inert filler, Flame retardant, curing agent, is characterized in that:

[0031] The ratio of the constituent materials of the flame-retardant silicone rubber heat-shrinkable sleeve is: by weight parts,

[0032]

[0033] The organopolyorganosiloxane may be a liquid or a highly viscous substance, preferably having a viscosity of 103 to 108 mm2 / s at 25°C.

[0034] The specific surface area of the silica is at least 50m 2 / g; the silica is fumed silica or precipitated silica or a mixture of the two; the silica is hydrophilic or hydrophobic silica or a mixture of the two.

[0035] The inert filler is one or a mixture of titanium oxide, aluminum oxide, talcum powder and mica powder.

[0036] The flame...

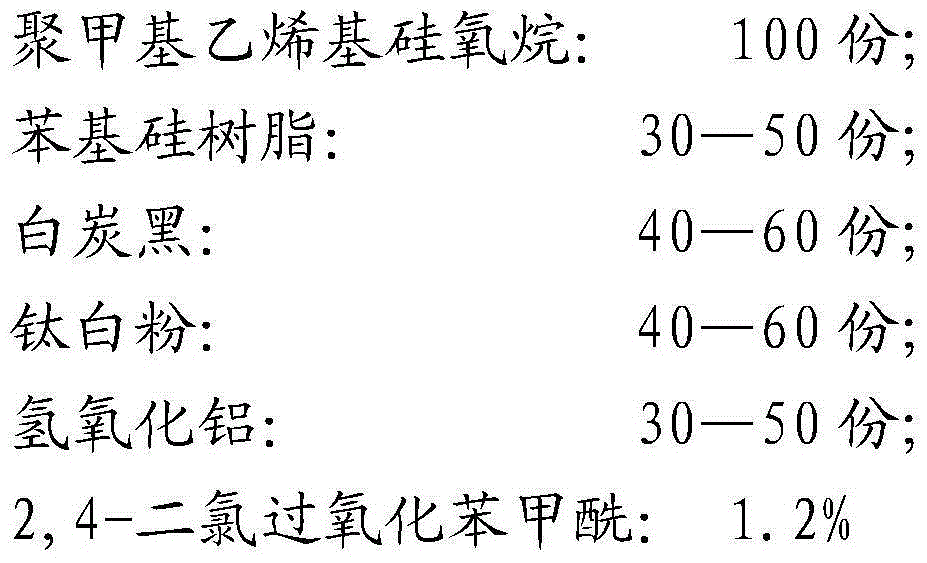

Embodiment approach 1

[0048] Take 100 parts of polymethylvinyl siloxane, 30 parts of white carbon black, 50 parts of phenyl silicone resin, 50 parts of titanium dioxide, 40 parts of aluminum hydroxide and add 1.2% of 2,4-dichloroperoxide to the silica gel mixture Benzoyl, according to the preparation method of the above-mentioned flame-retardant silicone rubber heat-shrinkable sleeve, the flame-retardant silicone rubber heat-shrinkable sleeve is obtained;

[0049] Material properties: Tensile strength: 12MPa

[0050] Elongation at break: 260%

[0051] Oxygen index: 28

[0052] Tear strength: 23

Embodiment approach 2

[0054] Take 100 parts of polymethylphenyl vinyl siloxane, 50 parts of white carbon black, 40 parts of phenyl silicone resin, 50 parts of silicon micropowder, 50 parts of zinc borate, 1 part of platinum flame retardant and add 1.2% of silicone rubber mixture 2,4-dichlorobenzoyl peroxide, according to the preparation method of the above-mentioned flame-retardant silicone rubber heat-shrinkable sleeve to make flame-retardant silicone rubber heat-shrinkable sleeve;

[0055] Material properties: Tensile strength: 11MPa

[0056] Elongation at break: 270%

[0057] Oxygen index: 32

[0058] Tear strength: 20KN / m

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com