Oil pump noise test device and test method

A technology of testing equipment and testing methods, used in pump testing, mechanical equipment, liquid variable capacity machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

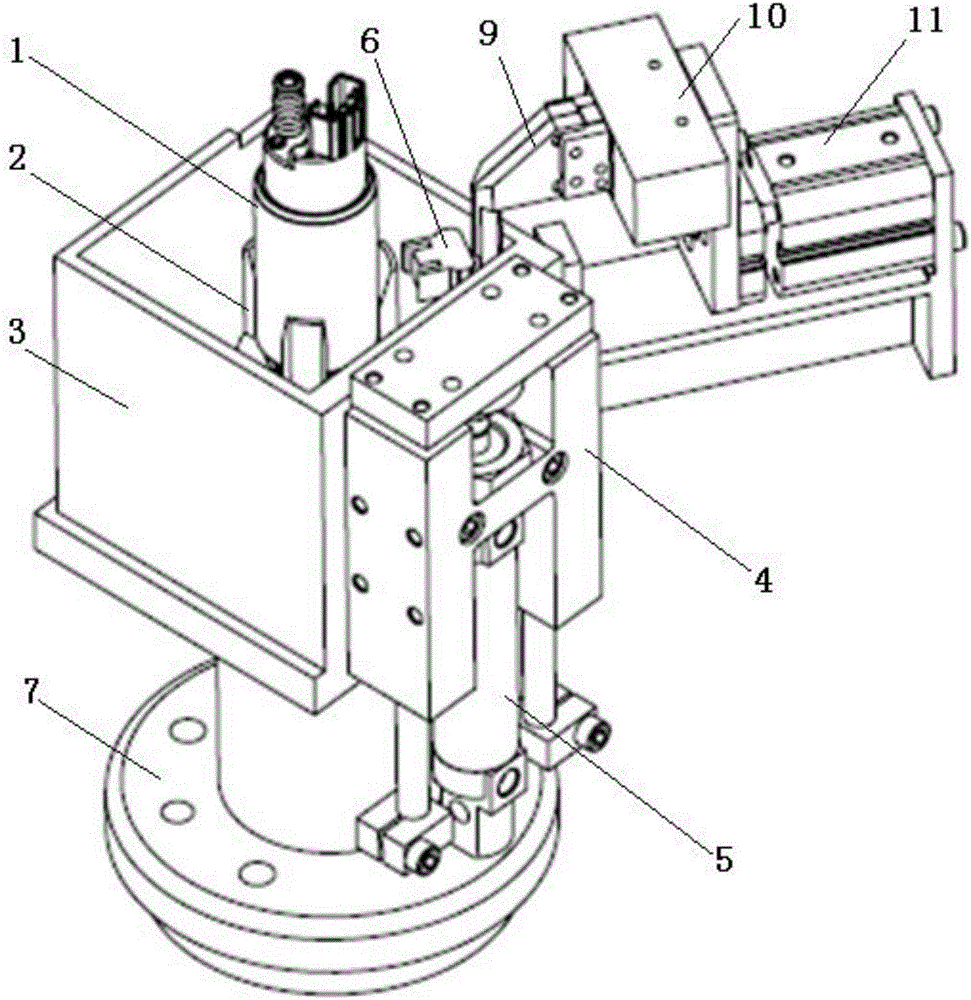

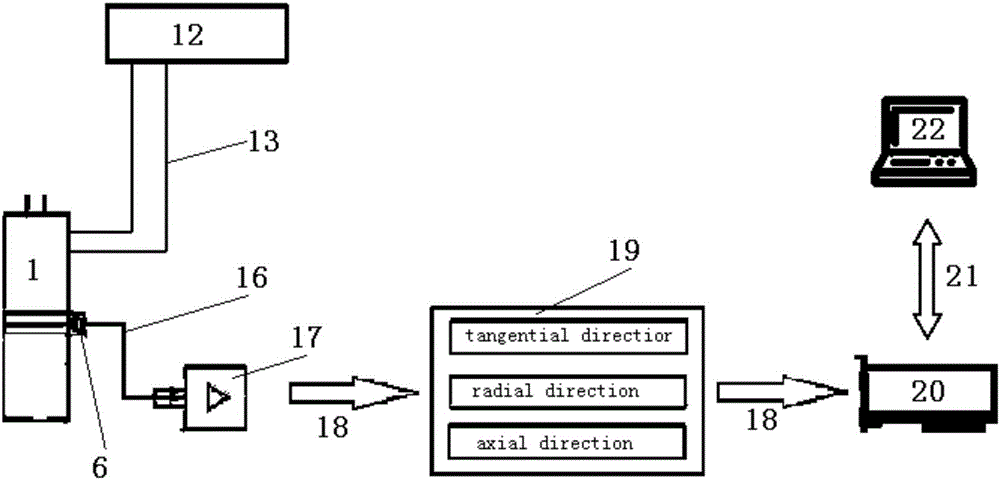

[0071] Such as figure 1 As shown, the oil pump noise test equipment includes a base support frame 2, a base support cylinder 5, and a vibration sensor unit 6;

[0072] The upper end of the oil pump 1 to be tested is suspended and fixed;

[0073] The base support frame 2 moves up and down with the expansion and contraction of the base support cylinder 5 push rod;

[0074] When the base support frame 2 moves to the upper end, it supports the oil pump 1 to be tested;

[0075] When the base support frame 2 moves to the lower end, the oil pump 1 to be tested is separated from the base support frame 2 and is in a suspended state;

[0076] The vibration sensor unit 6 can be assembled and fixed on the casing of the oil pump 1 to be tested;

[0077] The vibration sensor unit 6 is used to detect and output vibration signals.

[0078] In the oil pump noise testing equipment of Embodiment 1, when preparing for the noise test of the oil pump 1 to be tested, the ejector rod of the base ...

Embodiment 2

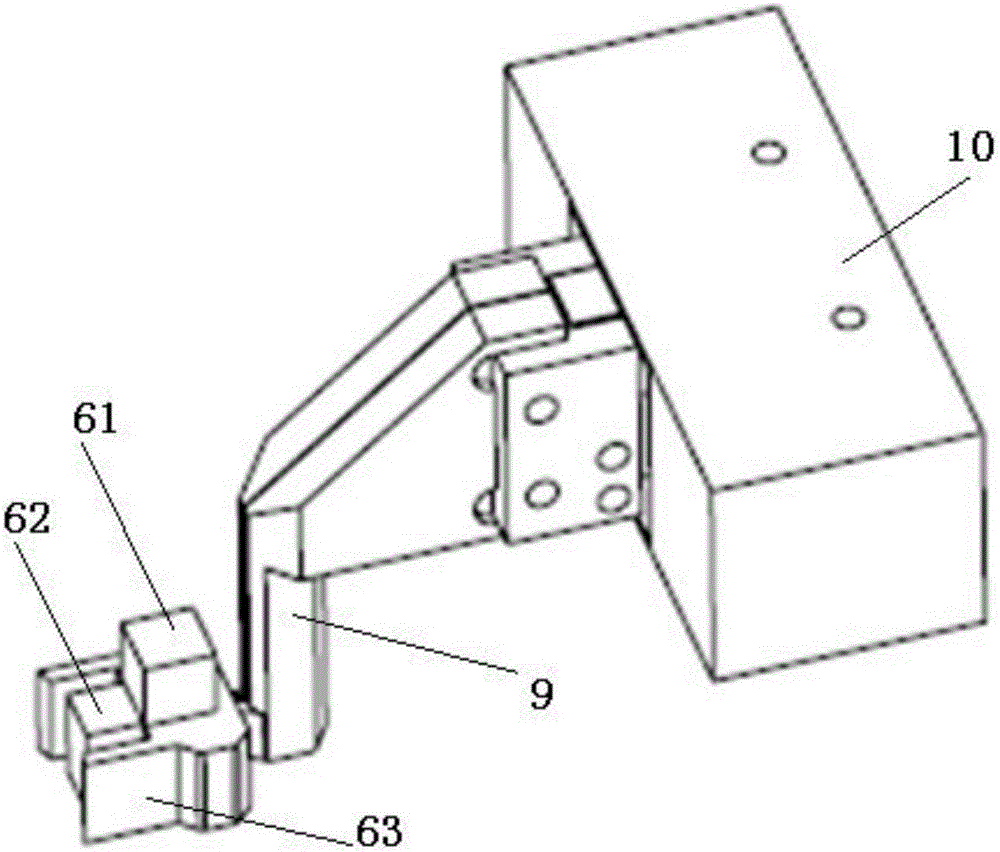

[0080] Based on the oil pump noise test equipment of embodiment one, such as figure 2 As shown, the vibration sensor unit 6 includes an acceleration sensor 61, a magnet 62, and a bracket 63;

[0081] Both the acceleration sensor 61 and the magnet 62 are installed and fixed on the bracket 63;

[0082] The casing of the oil pump to be tested is made of magnetically conductive material;

[0083] The vibration sensor unit 6 is installed and fixed on the casing of the oil pump 1 to be tested through the combination of the adsorption force of the magnet 62 .

[0084] Preferably, the casing of the oil pump 1 to be tested is cylindrical, and the matching surface between the front end of the vibration sensor unit 6 and the casing of the oil pump 1 to be tested is an arc surface.

[0085] Preferably, the magnet 62 is fixed on the front end of the bracket 63; the magnet 62 and the front end of the bracket 63 jointly constitute the mating surface between the front end of the vibration ...

Embodiment 3

[0088] Based on the first embodiment, the oil pump noise testing equipment also includes an oil supply tank 3, a guide block 4, and a flange 7;

[0089] The flange 7 is used to be fixed on the fuel tank;

[0090] The oil tank 3 is fixed on the flange 7;

[0091] The guide block 4 is fixed on the outer wall of the oil tank 3;

[0092] The base support cylinder 5 is fixed on the flange 7 , and the push rod of the base support cylinder 5 moves telescopically along the guide rail of the guide block 4 .

[0093] Preferably, the guide block 4 is an I-shaped guide block.

[0094] In the oil pump noise testing equipment of Embodiment 3, the ejector rod of the base support cylinder 5 moves up and down along the guide rail of the guide block 4, driving the oil pump support base 2 to stably support the oil pump 1 to be tested, or to leave the oil pump 1 to be tested smoothly to ensure that the oil pump to be tested is in the dangling state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com