Hydraulic system of coil stripping car

A technology of hydraulic system and trolley, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., and can solve the problems of low feedback sensitivity of lift cylinder pressure changes, sticking, coil inner and outer rings Extrusion damage between layers and other problems, to achieve the effect of stable pressure, real pressure value, and avoid extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

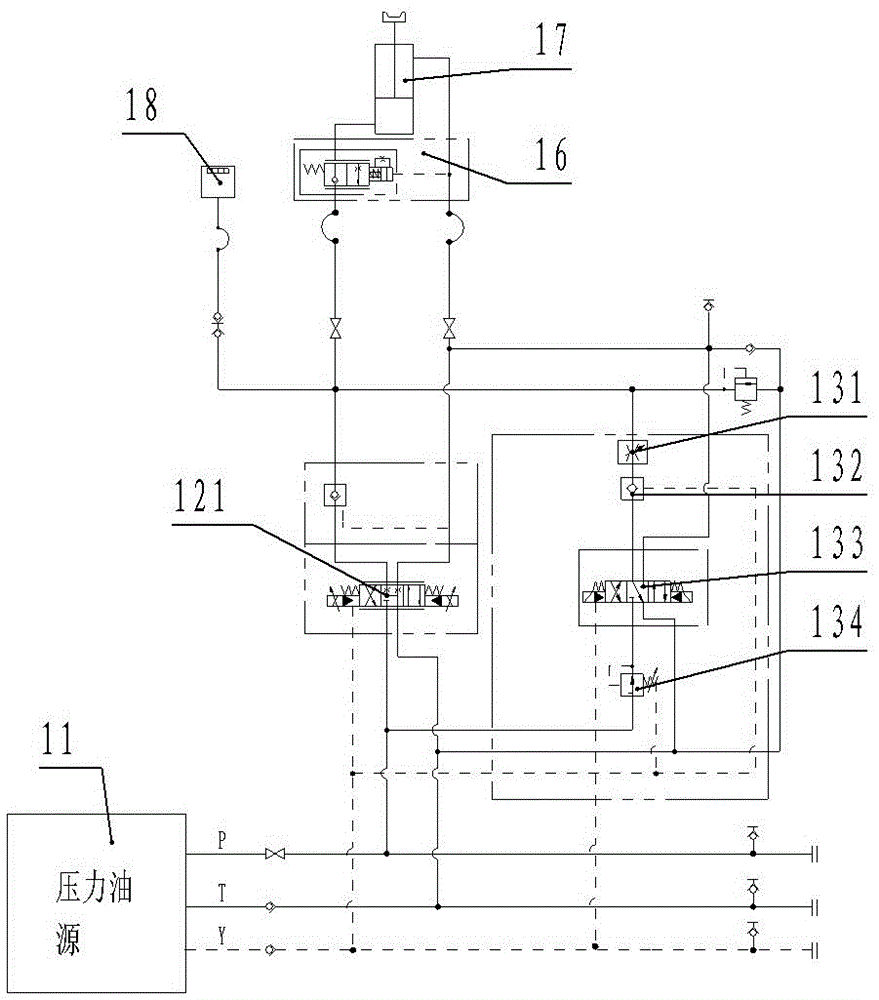

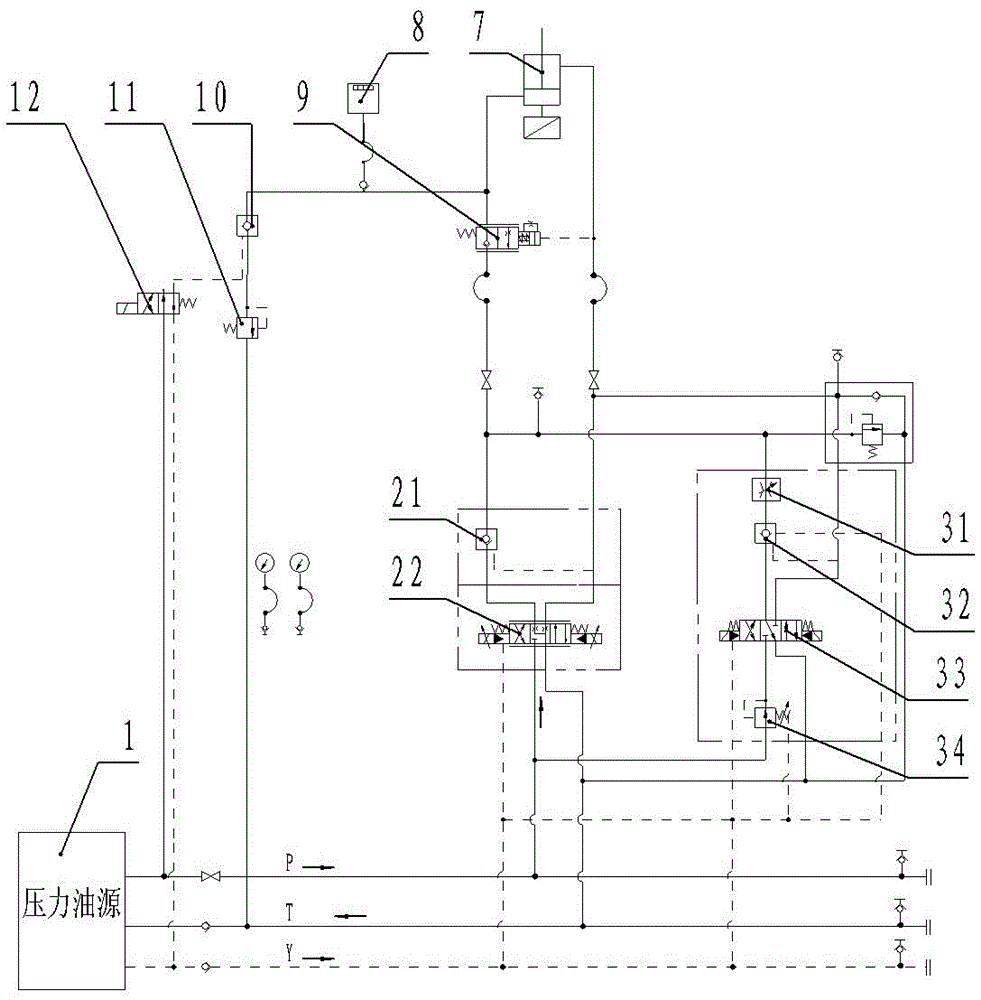

[0012] figure 2 The hydraulic system of the coil unloading trolley shown includes a lifting cylinder 7 located at the bottom of the coil unloading trolley, and the lifting cylinder 7 supplies oil to it through two branches, one of which is through the first hydraulic control reversing valve 22 and the pressure The oil source 1 is connected, and the first hydraulic control lock 21 is provided between the rodless cavity of the lifting cylinder 7 and the first hydraulic control reversing valve 22. The control end of the first hydraulic control lock 21 is connected to the rod cavity of the lifting cylinder 7. connection; another branch is provided with a second hydraulic control reversing valve 33, and a throttle valve 31 and a second hydraulic control lock 32 are sequentially connected between the rodless cavity of the lift cylinder 7 and the second hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com