A reusable sealed connection structure

A connection structure and sealing groove technology, applied in the direction of sealing surface connection, non-detachable pipe connection, pipe/pipe joint/pipe fitting, etc., to achieve the effect of low leakage rate, reduced sealing leakage rate, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

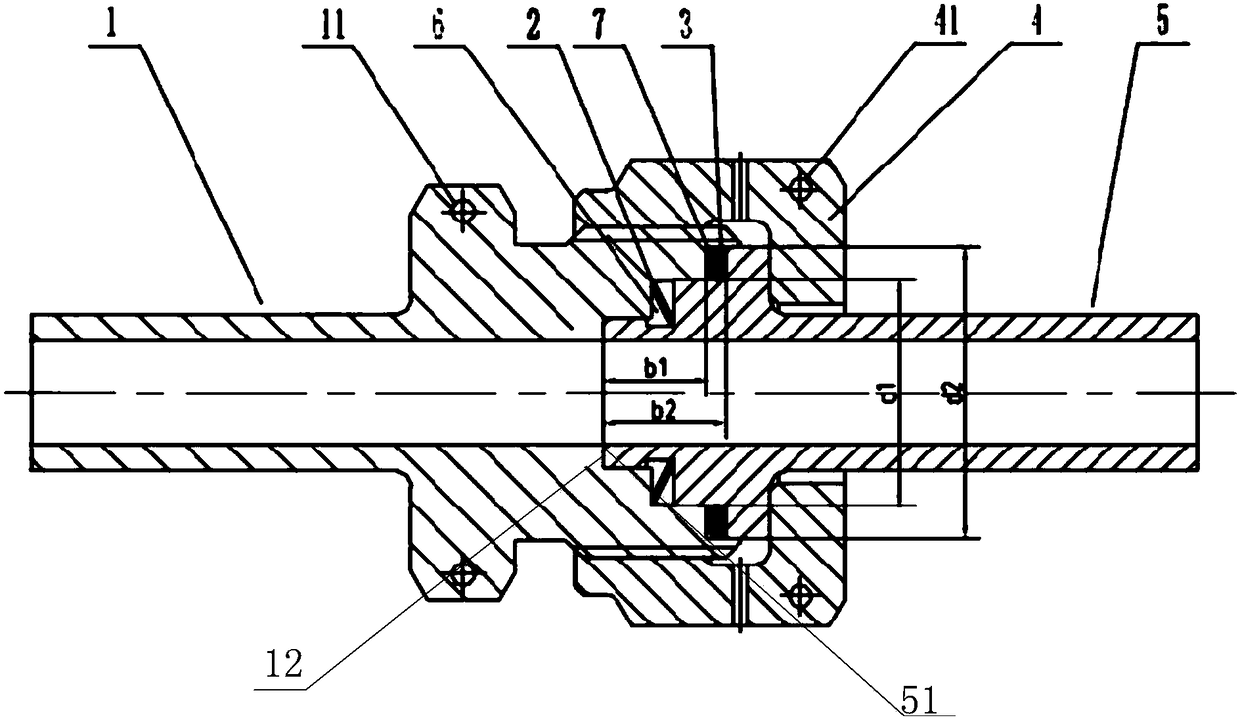

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] figure 1 A schematic structural view of the reusable sealing connection structure provided by the embodiment of the present invention is shown. like figure 1 As shown, the connection structure includes a concave stepped joint 1 , a metal dish ring 2 , a rubber O-ring 3 , an outer casing nut 4 and a convex stepped joint 5 . in,

[0023] The concave stepped joint 1 is hollow, and one end is used for connecting with pipelines. During specific implementation, one end of the concave step joint 1 ( figure 1 (middle is the left end) is welded with the pipeline, and the hollow structure of the concave stepped joint 1 can transport propellant together with the pipeline.

[0024] The convex stepped joint 5 is hollow, and one end is used to connect with another pipeline. During specific implementation, one end of the convex step joint 5 ( figure 1 (middle is the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com