Flexible graphite metal wave tooth composite gasket sealing structure

A technology of flexible graphite and sealing structure, which is applied in the direction of engine sealing, flange connection, pipe/pipe joint/pipe fitting, etc. It can solve the problems of non-redundant performance sealing quantitative control, short sealing leakage channel, etc., and achieve sealing leakage. The effect of low efficiency and enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

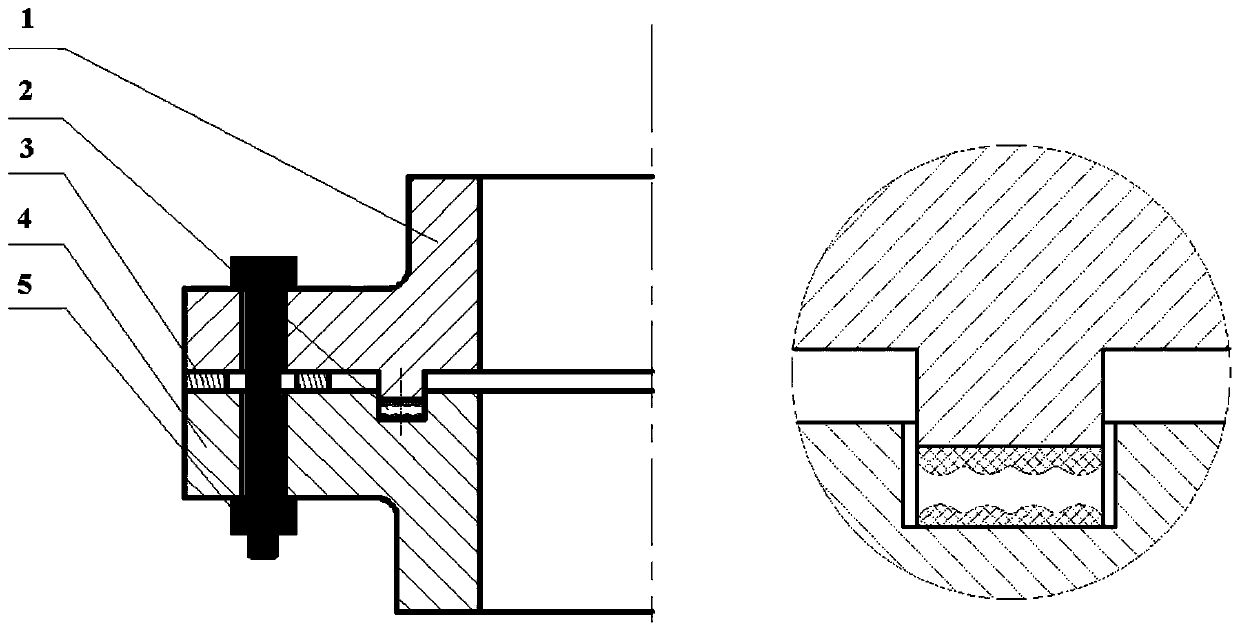

[0045] A flexible graphite metal wave-tooth composite gasket sealing structure, used for sealing and leak-proofing the docking port of the propellant delivery pipeline, such as figure 1 As shown, it mainly includes tenon flange, flexible graphite metal corrugated tooth composite gasket, metal limit ring, and groove surface flange. The corresponding numbers in the figure are: 1- tenon face flange, 2- flexible graphite metal corrugated tooth Composite gasket, 3-metal limit ring, 4-groove flange, 5-fastening screw, tenon flange and groove flange are all symmetrical ring structures with L-shaped edges, and the two flanges pass through The bottom face is matched and connected, and the hollow part is used for the butt joint of the upper and lower ends of the pipeline. The tenon face flange and the groove face flange are fixed by fastening screws to form a flange sealing structure, and are set outside the joint of the upper and lower propellant pipelines.

[0046] Sealing grooves are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com