Adhesion control program's automatic and rapid online testing method and testing module

An adhesion control and online testing technology, applied in the field of rail transit, can solve the problems of the semi-physical simulation test system difficulty, the consumption of large man-hours, manpower and material resources, and the inapplicability of the adhesion control program test, so as to achieve a safe and reliable test process and reduce development. Period, easy to quickly and accurately locate and find the effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

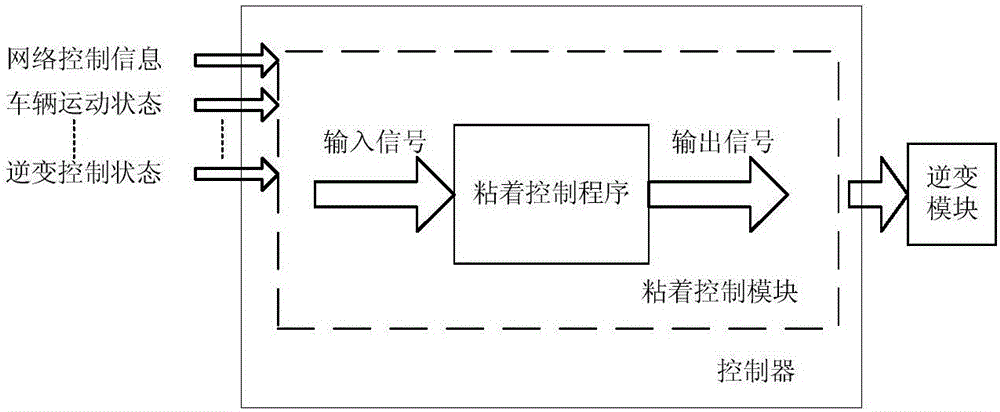

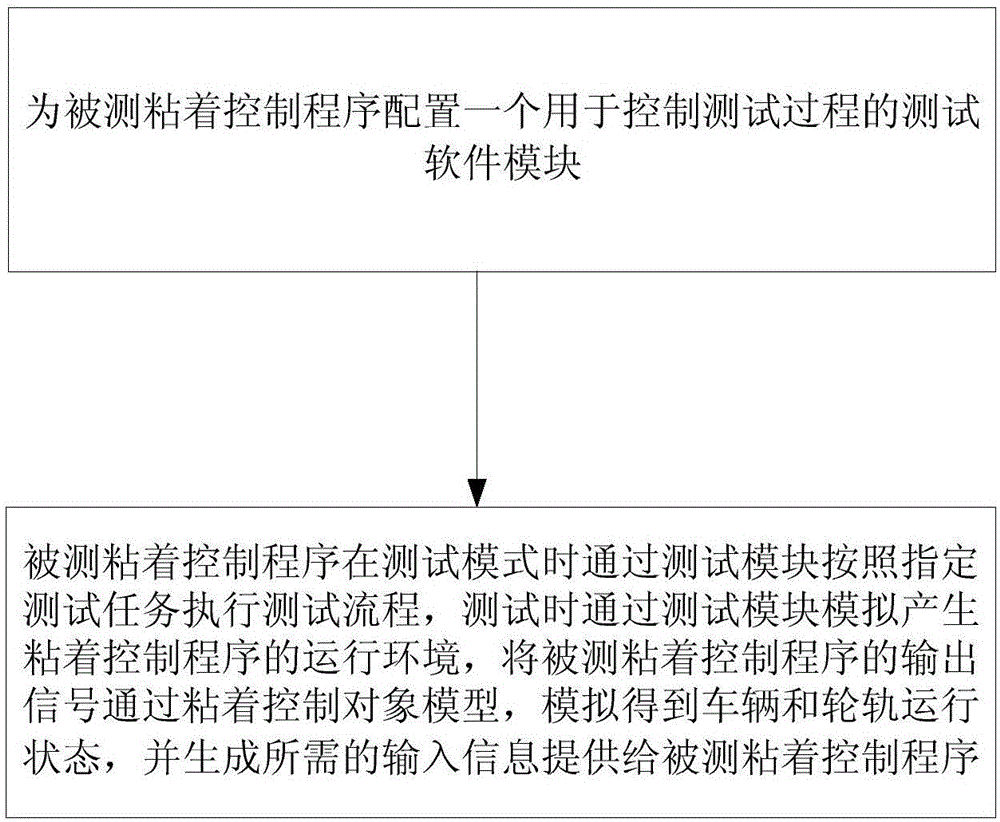

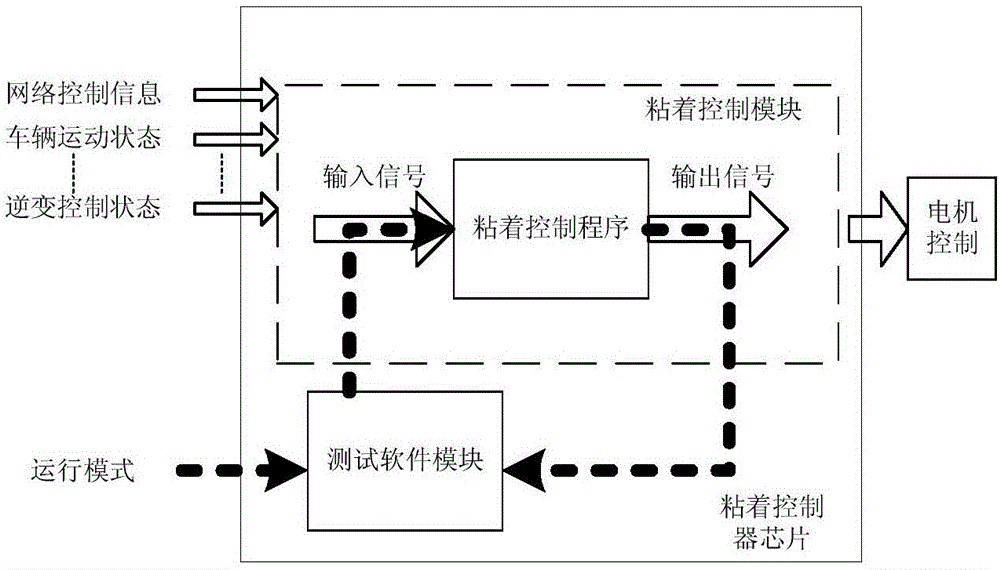

[0046] Such as figure 2 , 3 As shown, the automatic fast online testing method of the adhesion control program in this embodiment, the steps include:

[0047] 1) Configure a test module for controlling the test process for the adhesion control program under test;

[0048] 2) The sticky control program under test executes the test process according to the specified test task through the test module in the test mode, and simulates the running environment of the sticky control program through the test module during the test, and passes the output signal of the sticky control program under test through the pre-established The adhesion control object model simulates the running state of the vehicle and wheel-rail, and generates the input information required by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com