Coreless linear motor of embedded I-shaped coil

A linear motor, I-shaped technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor connection, uneven speed, low thrust coefficient, etc., and achieve good thrust uniformity and high space. The effect of utilization, high structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

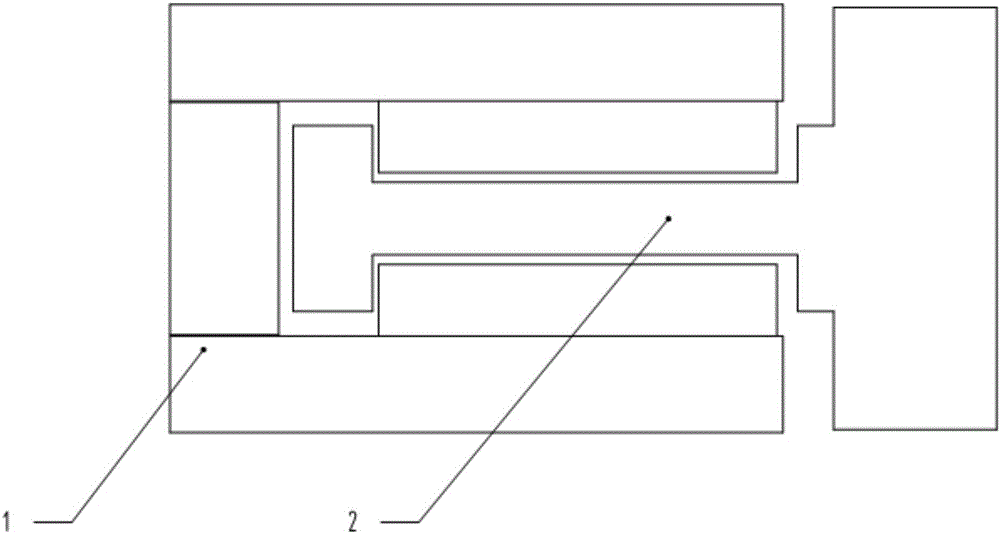

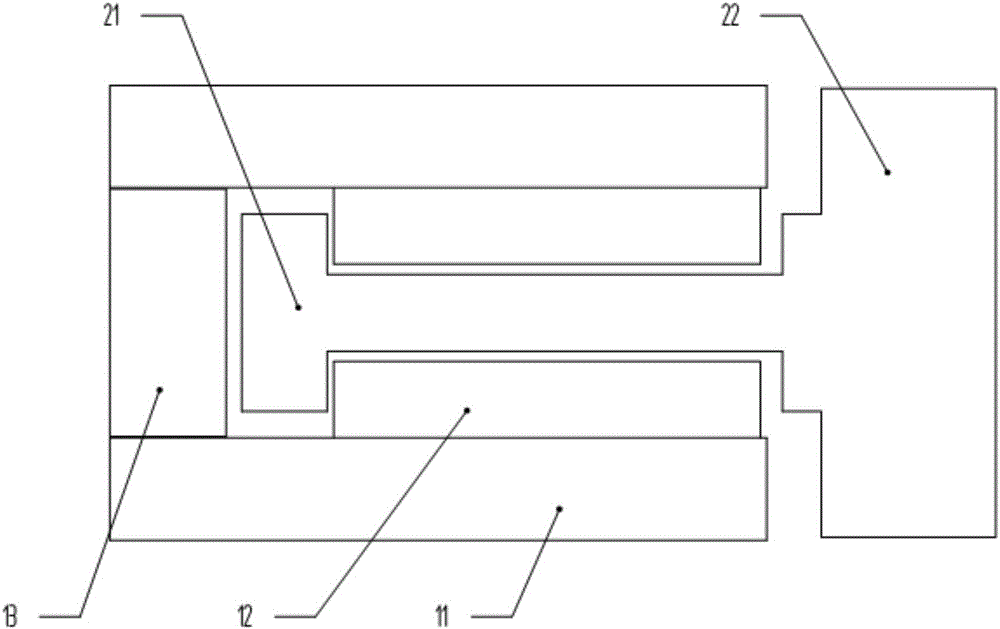

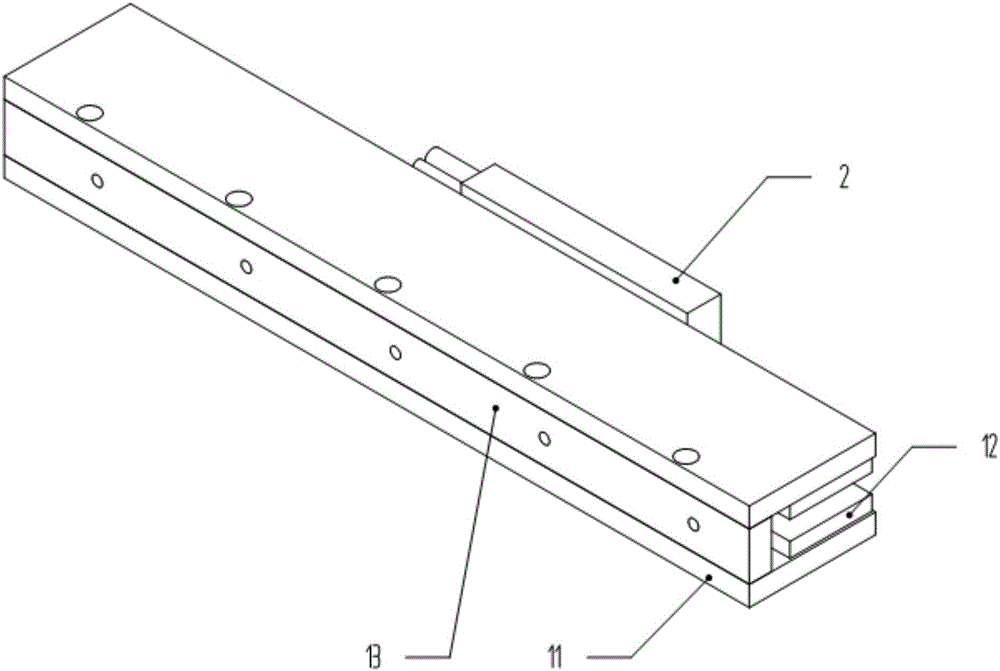

[0022] refer to figure 1 , figure 2 and Figure 4 As shown, the present invention provides a coreless linear motor with an embedded I-shaped coil, including a U-shaped stator 1, an I-shaped mover 2, and the I-shaped mover 2 includes an I-shaped coil 21 and The mover mounting plate 22 located at one end of the I-shaped coil 21, the other end of the I-shaped coil 21 is placed in the U-shaped stator 1, and the I-shaped coil 21 is composed of a U-shaped coil winding 211, The V-direction coil winding 212 and the W-direction coil winding 213 are composed of three-phase coil windings. The coil windings are embedded in each other and evenly woven. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com