Regulator flow damping

A technology of flow regulator and regulating valve, which is applied in the fuel valve, transportation and packaging of machine/engine, turbine/propulsion device, etc., can solve problems such as excess, and achieve the effect of reducing leakage sensitivity and improving pollution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

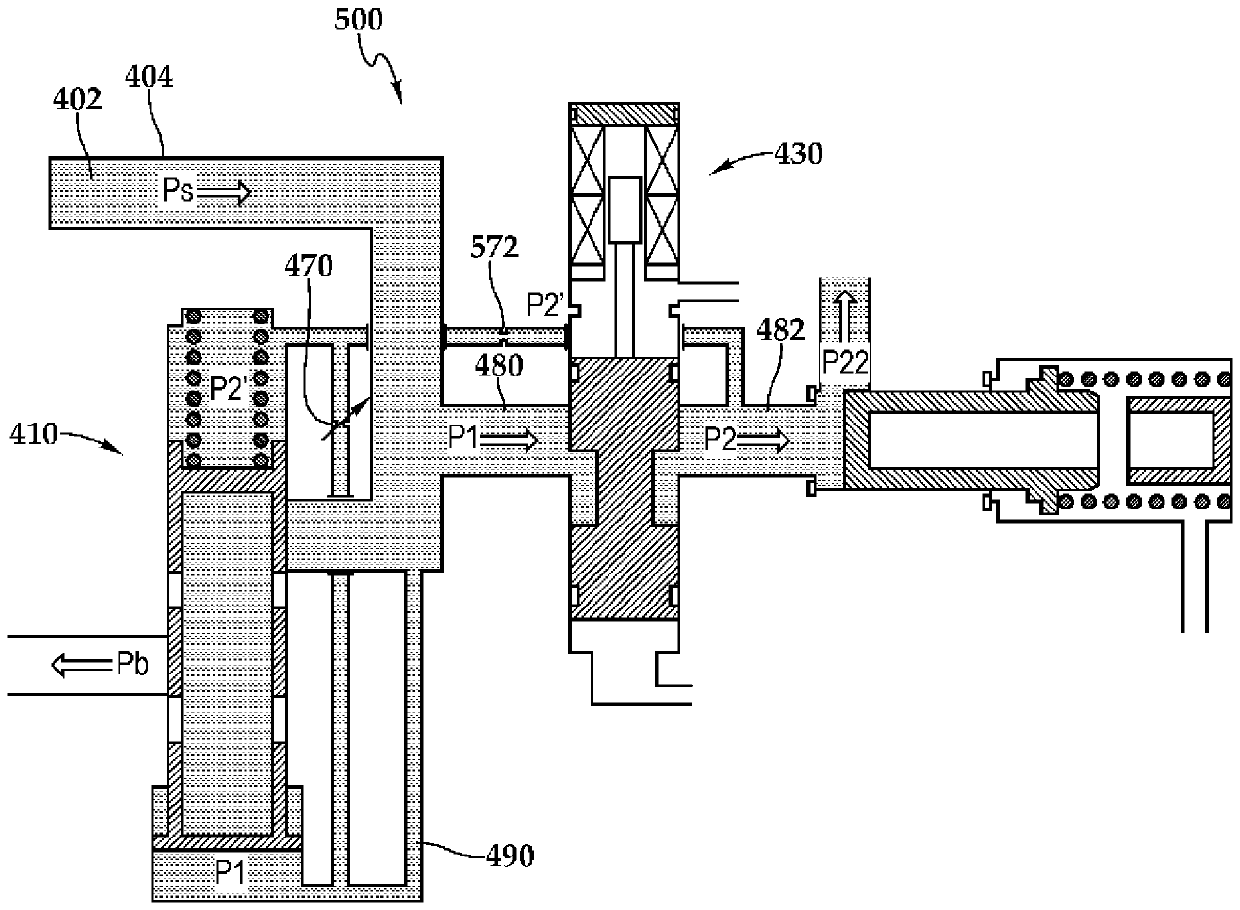

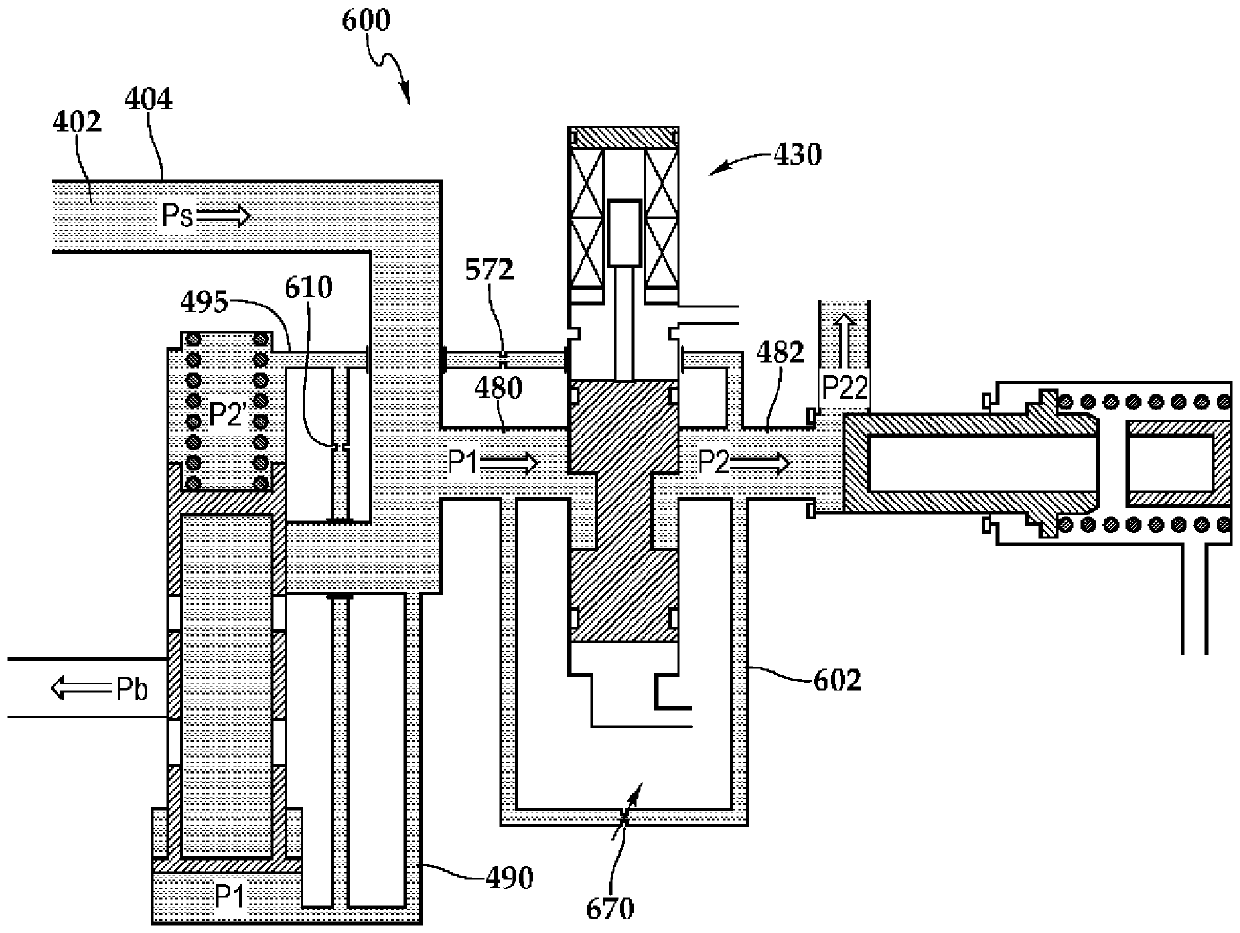

[0020] This document describes systems and techniques for regulating fluid flow with a dampened response. A flow regulator valve can maintain fluid flow provided at the inlet of the flow regulator. Two choke schemes for flow regulator systems include the use of laminar leak path chokes or orifices in non-flow lines.

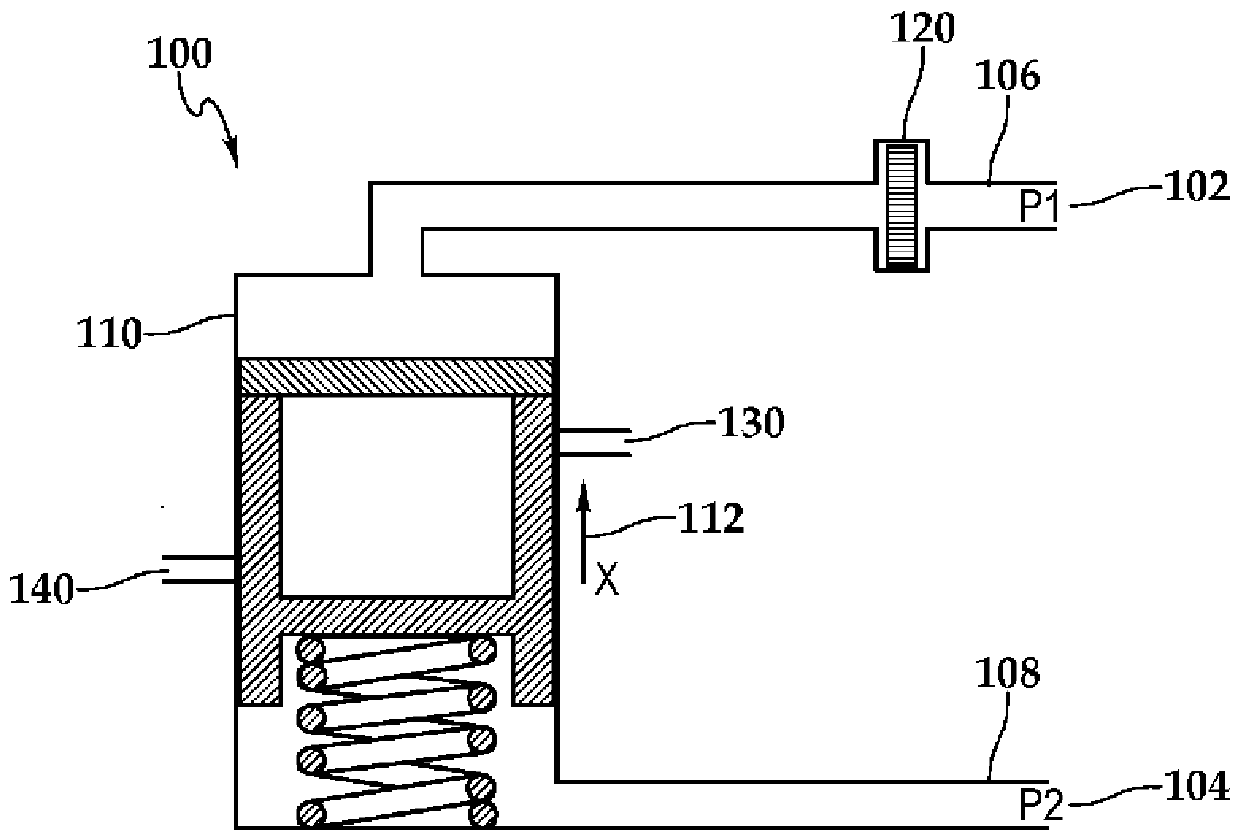

[0021] figure 1 is a schematic diagram of a prior art fluid flow regulator 100 using laminar flow leak path chokes. Regulator 100 includes two different pressure signals at 102 and 104 . The fluid at 102 is fluidly connected to fluid passage 106 and the fluid at 104 is fluidly connected to fluid passage 108 .

[0022] Fluid passage 106 is fluidly connected to outlet fluid passage 108 via bypass valve 110 and laminar flow-resistance orifice 120 . Bypass valve 110 includes a plurality of ports (not shown) that fluidly connect inlet fluid passage 130 to outlet fluid passage 140 . Bypass valve 110 exhibits a regulator speed, generally indicated by arrow 112 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com