A dust-absorbing environmental protection sheet material clamping and conveying mechanism

A clamping conveying and dust-absorbing technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of poor effect, unsatisfactory effect, and low cutting efficiency, so as to achieve good effect and prevent Harm, the effect that the environmental protection efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

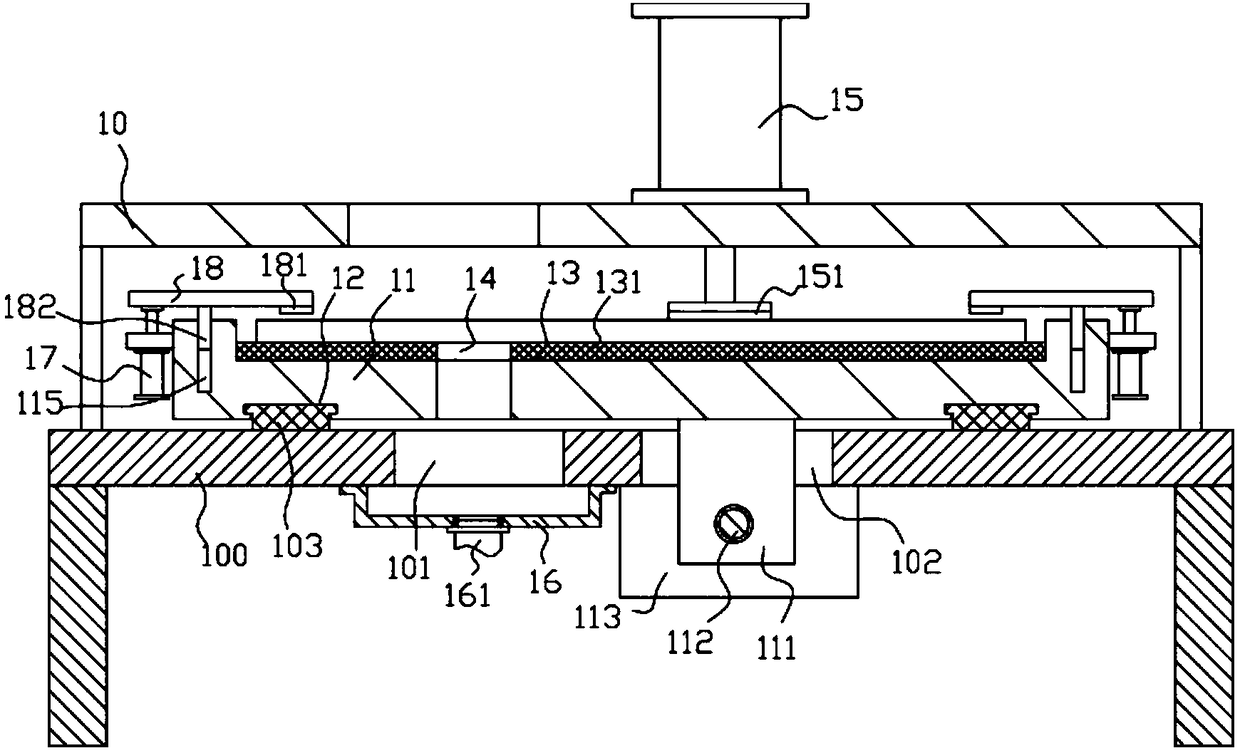

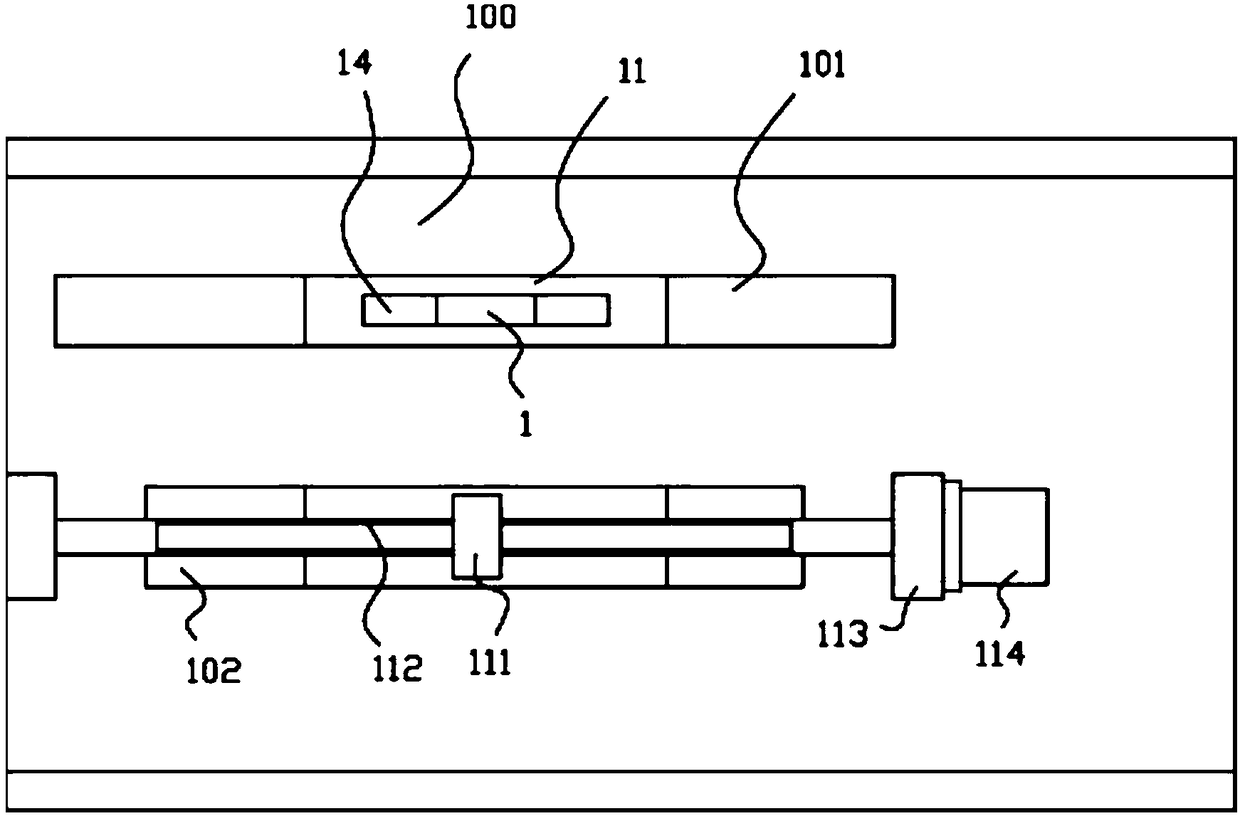

[0015] Example: see Figure 1 to Figure 2 As shown, a dust-absorbing type environmental protection sheet material clamping and conveying mechanism includes a frame 100, an upper support frame 10 is fixed in the middle of the top plate of the frame 100, and the middle of the top plate of the frame 100 has an air suction channel 101 and a conveying Through groove 102, guide track 103 is fixed on both sides of the top surface of the top plate of frame 100, and the bottom surface of moving plate 11 has chute 12, and the top of guide track 103 is inserted and sleeved in chute 12, and the top surface middle part of moving plate 11 There is a placement groove 13, and the bottom surface of the placement groove 13 is fixed with an elastic plate 131. The bottom surface of the elastic plate 131 and the placement groove 13 has a through groove 14 aligned up and down, and the through groove 14 communicates with the suction through groove 101 up and down, and the moving plate The bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com