Wire electric discharge machine

A technology of wire electric discharge machine and wire electrode, which is applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve problems such as wiring failure, wire electrode winding, time-consuming, etc., and achieve the effect of shortening wiring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

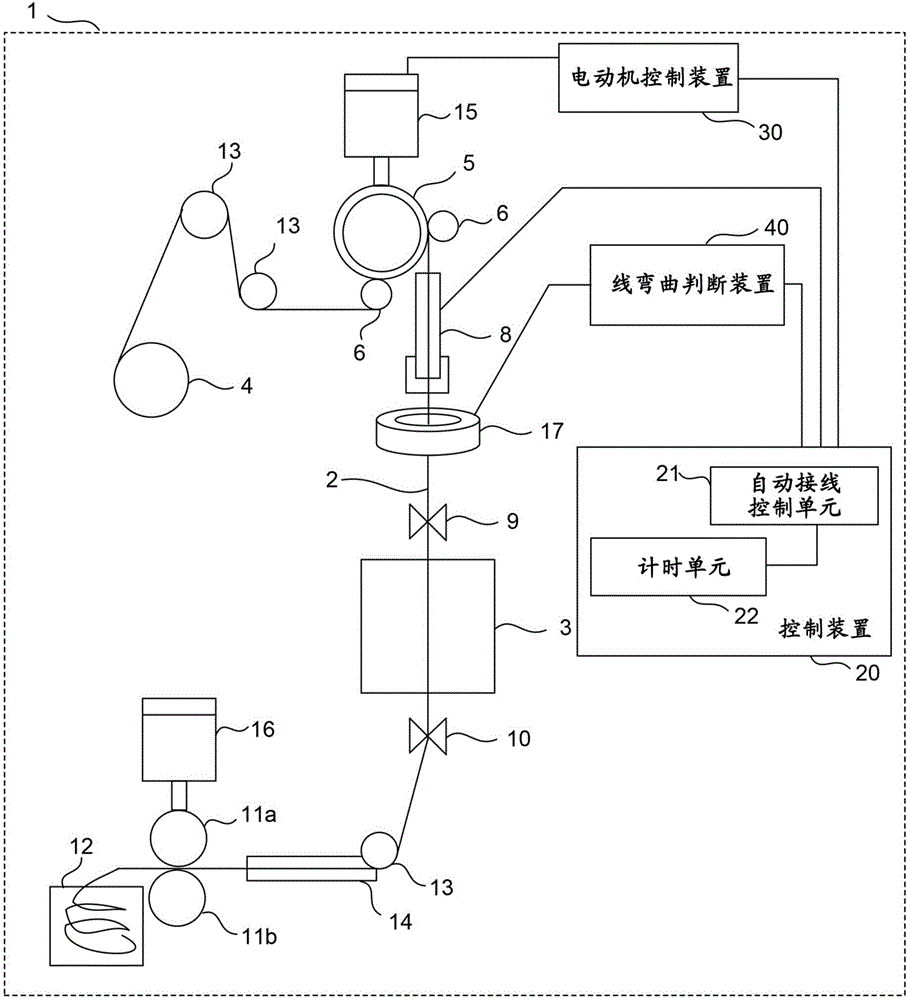

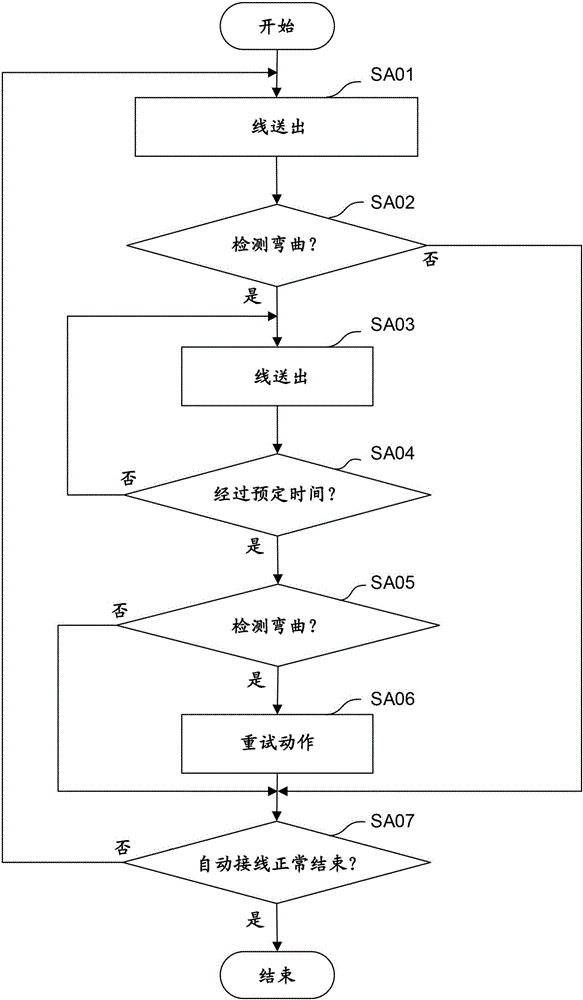

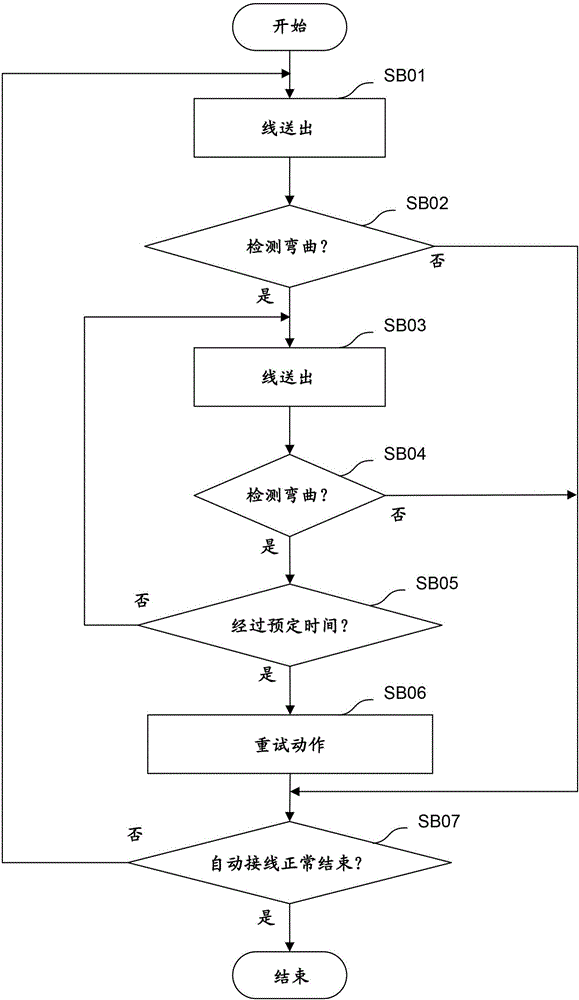

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0018] In the wire electric discharge machine according to the present invention, even if the bending (flexure) of the wire electrode is detected during the automatic connection of the wire electrode, the retry operation is not performed immediately, but the presence of radio is determined again after a certain period of time. When the bending of the wire electrode is detected again, a retry operation is performed, and if the bending of the wire electrode is not detected again, the retry operation is not performed and the normal connection operation is returned. Therefore, when the tip of the wire electrode is clogged and bent, etc., the vibration or deformation of the wire electrode itself eliminates the clog and naturally eliminates the bending, and no retry operation is performed when the normal connection is continued. Looking forward to shortening the wiring time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com