Indoor cable inlet transformer winding short-circuiting device

A technology for transformer winding and cable entry, which is applied to the casing of the measuring device, etc., can solve the problems of independent oil tank pollution, personal injury to equipment, damage, etc., to save wiring time, ensure timely commissioning, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

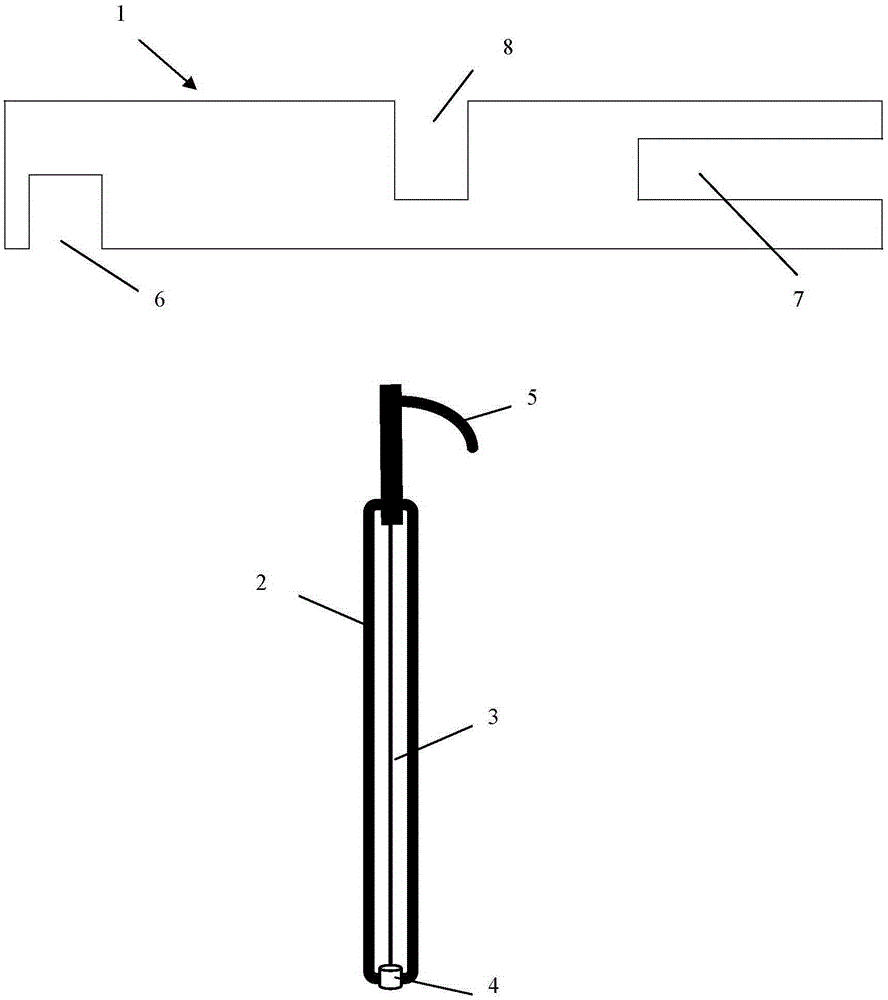

[0012] The indoor cable incoming transformer winding short-circuit device provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the indoor cable inlet transformer winding short-circuit device provided by the present invention includes an insulating plate 1, an insulating rod 2, a lead wire 3 with low dielectric strength, a short-circuit connection interface 4 and a hook 5; wherein the insulating plate 1 is a vertically arranged rectangular plate One end is recessed upward on the long side below to form a card slot 6, the middle of the short side of the other end is formed inwardly to form a groove 7, and at the same time, the long side above is recessed downward to form an insulating rod setting groove 8 The insulating rod 2 is composed of a main rod 9 of a hollow structure and a connecting rod 10 connected to one end of the main rod 9. The middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com