Welding structure and method for vacuum brazing of metal plates and metal fins

A metal fin, welding structure technology, applied in welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of unstable welding quality, large fin thickness, low connection strength, etc., to solve the problem of unstable welding quality, The effect of ensuring the spacing size and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

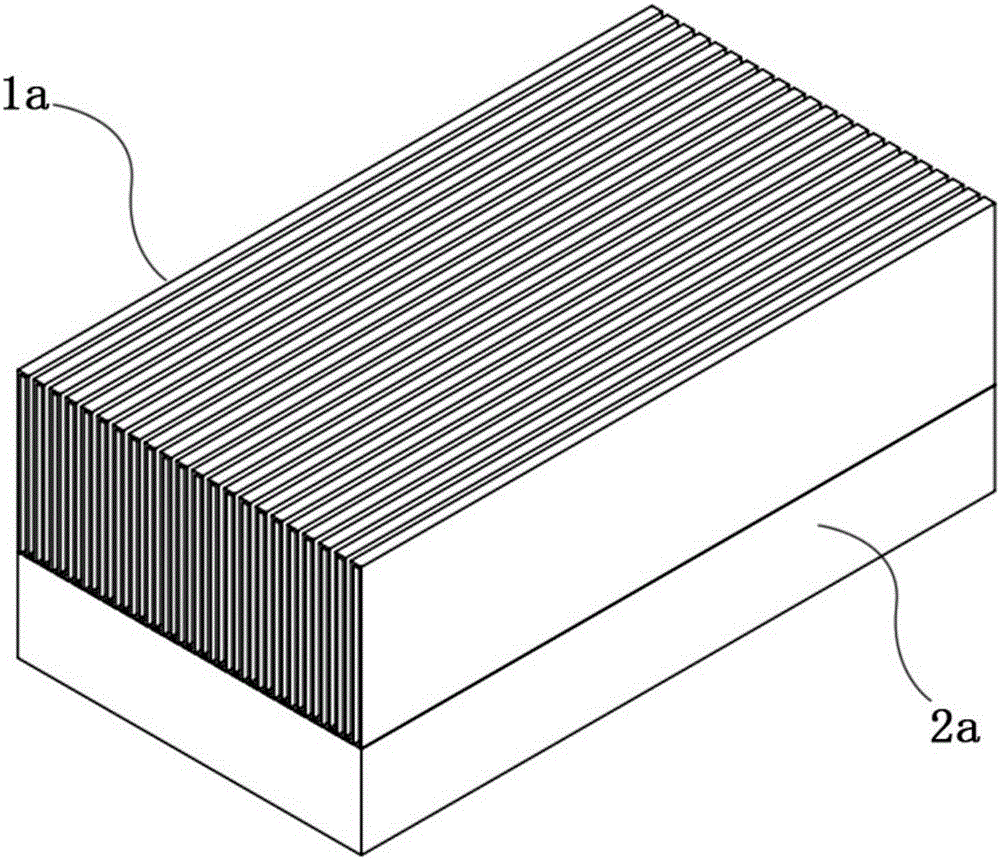

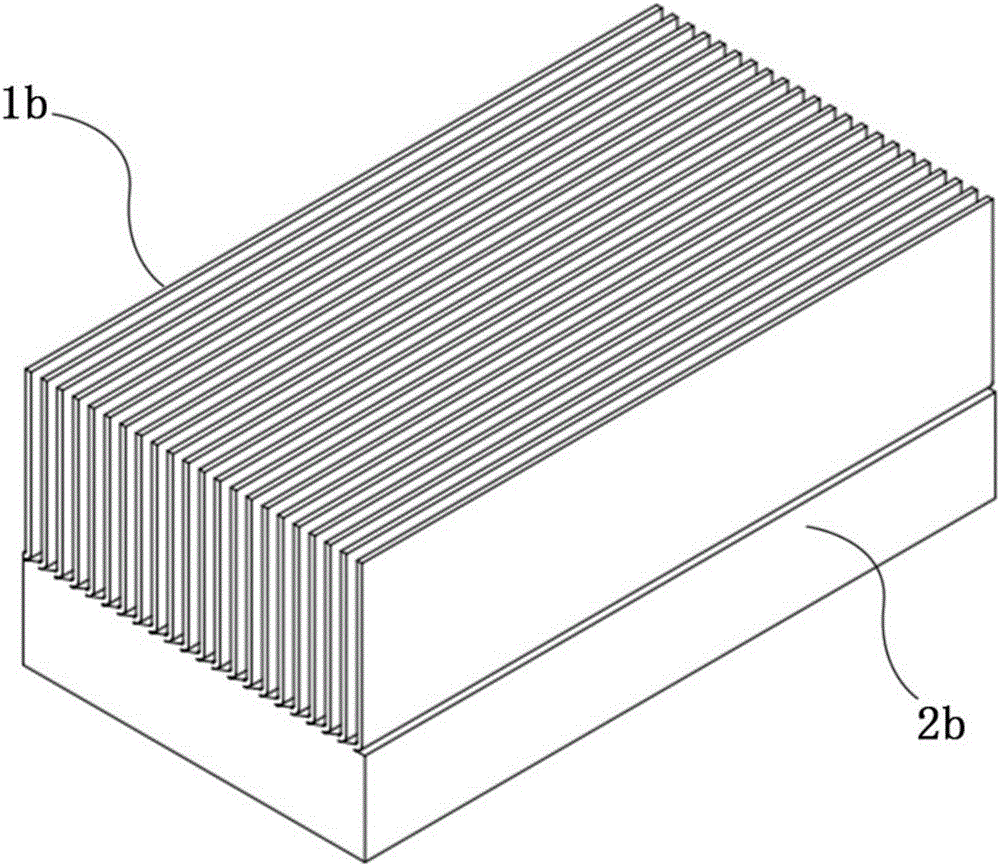

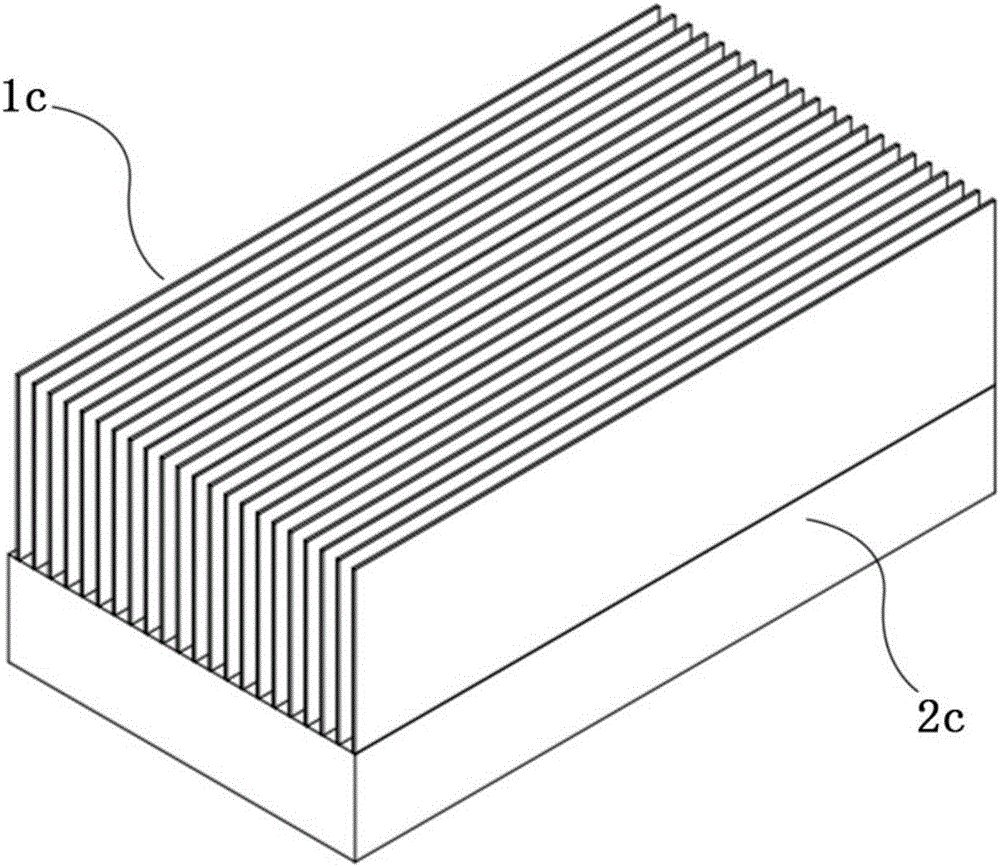

[0041] The vacuum brazing welding structure of a metal plate and a metal fin of the present invention is especially suitable for processing heat sink products with denser and thinner fins in main applications. The present invention also adopts metal fins, but the metal fins can be composed of a plurality of individual metal sheets (strengths) or integral metal folded fins, but it is different from the vacuum brazing structure of the existing radiators. Invention During the manufacturing process, the overall volume of the metal fins already includes the volume of the solid base, that is to say, the metal fins that need to be made into a solid base are interspersed with metal fins that can be connected to the adjacent metal fins by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com