Welding method for stainless steel pipeline in benzene hydrogenation engineering

A welding method and stainless steel technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated, unreasonable, and unscientific manufacturing processes, achieve safe and reliable welding quality, reduce engineering construction costs, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The benzene hydrogenation engineering stainless steel pipeline welding method of the present invention uses a TIG pulse welder to weld 0Cr18Ni9, 00Cr19Ni11 and 0Cr18Ni10Ti brand stainless steel with manual tungsten argon arc welding, and is characterized in that comprising the following steps:

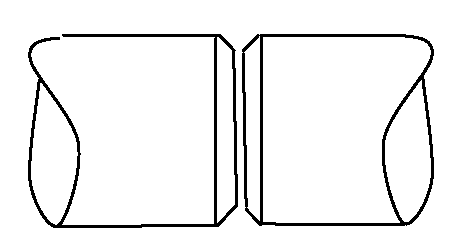

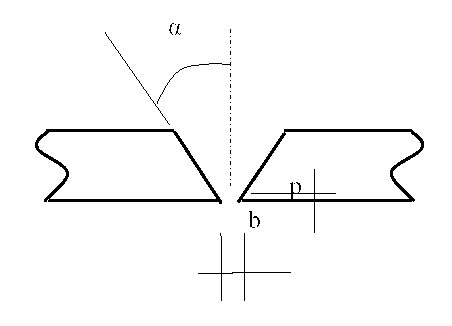

[0042] figure 1 It is a schematic diagram of the pipe-to-pipe butt joint groove structure according to the embodiment of the present invention, figure 2 It is a schematic diagram of the groove angle of the pipe-to-pipe butt joint of the embodiment of the present invention, and the pipe-to-pipe butt joint welding of the stainless steel pipeline is performed.

[0043] a. Pipe section cutting and bevel processing

[0044] Plasma arc or mechanical cutting is used to cut the pipe section, and mechanical methods are used to remove the oxidized pollution layer at the welding groove and the near seam area; the pipe joint with a pipe wall thickness of more than 3mm adopts machining gro...

Embodiment 2

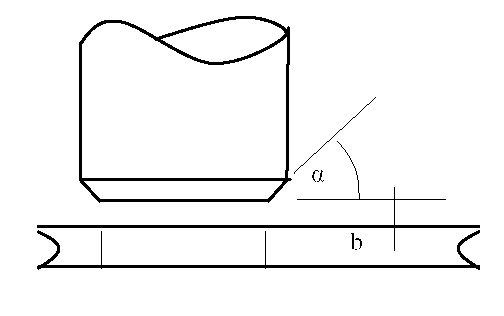

[0054] image 3 It is a schematic diagram of the groove angle of the pipe and the flange joint of the embodiment of the present invention, and the pipe and the flange joint of the stainless steel pipeline are welded by the saddle joint. Plasma arc or mechanical cutting is used, and the oxidation pollution layer is removed mechanically at the welding groove and the near seam area; the branch pipe joints with a pipe wall thickness of more than 3mm are processed by machining groove α=45+5°, p=0, b= 2.0~2.4mm.

[0055] Figure 5 It is a schematic diagram of the protection device for the welding joint between the pipe and the flange according to the embodiment of the present invention, and a protection device using a blind plate on the flange and partial argon filling in the pipe is provided for the joint with the flange. Other technical features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0057] In the welding of the branch pipe insertion type and the saddle type welding joint, except that the main pipe and the branch pipe are partially sealed with argon-filled protection device, other technical features are the same as those in embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com