Welding method for bottom plate of large stainless steel tank under high-temperature environment

A high-temperature environment, welding method technology, applied in welding equipment, welding/welding/cutting items, household containers, etc., can solve the problems of inconvenient welding of the bottom plate of large tanks, affecting the quality of the tank, and the unevenness of the bottom of the tank. Strict design, strong operability and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

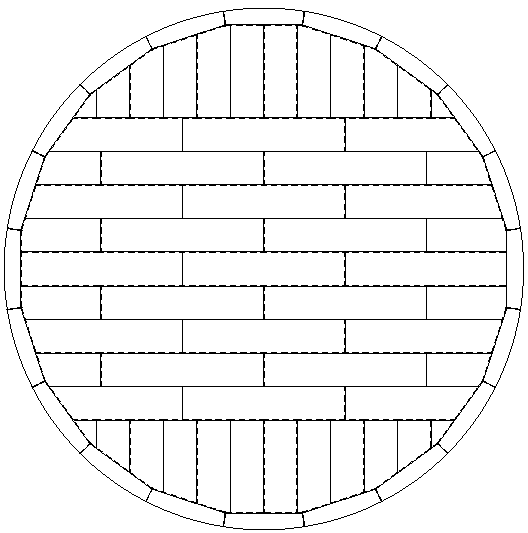

[0038] figure 1 It is the layout diagram of the bottom plate of the stainless steel tank according to the embodiment of the present invention. The welding method of the large stainless steel tank bottom plate under the high temperature environment of the present invention comprises the following steps:

[0039] a. Medium plate welding:

[0040] When welding the long weld seam, use a long back bar to flatten the bottom plate, or use a gantry plate welded on the bottom plate to clamp the channel steel to reduce welding stress.

[0041] During welding, welders should be evenly distributed, using basically the same process parameters, and welding at the same time; both long and short welds should be welded from the center to the outside; the first pass of welding adopts the segmented jump welding method, and the second pass uses the segmented backward method.

[0042] After the long weld seam of the bottom plate is welded, use a wooden hammer to lightly tap along the weld seam f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com