Method and system for teaching tracing of welding seam of electron beam welding machine

A technology of electron beam welding and electron beam, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low precision and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

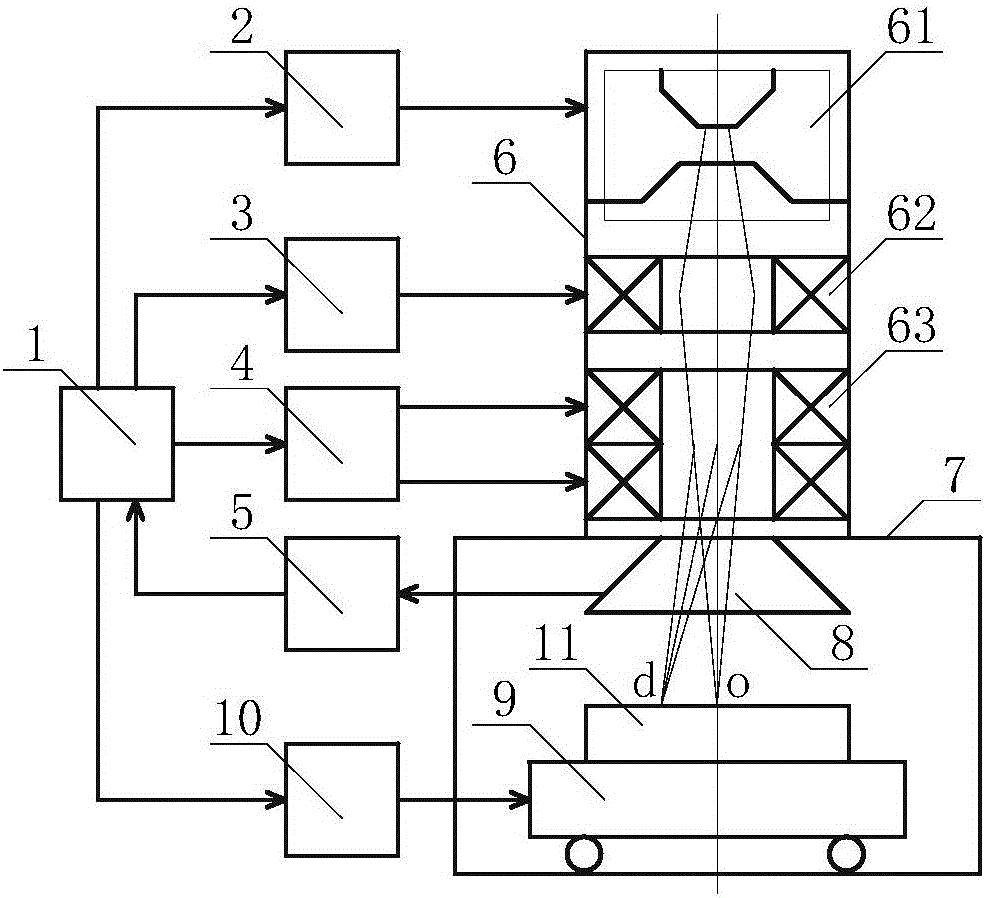

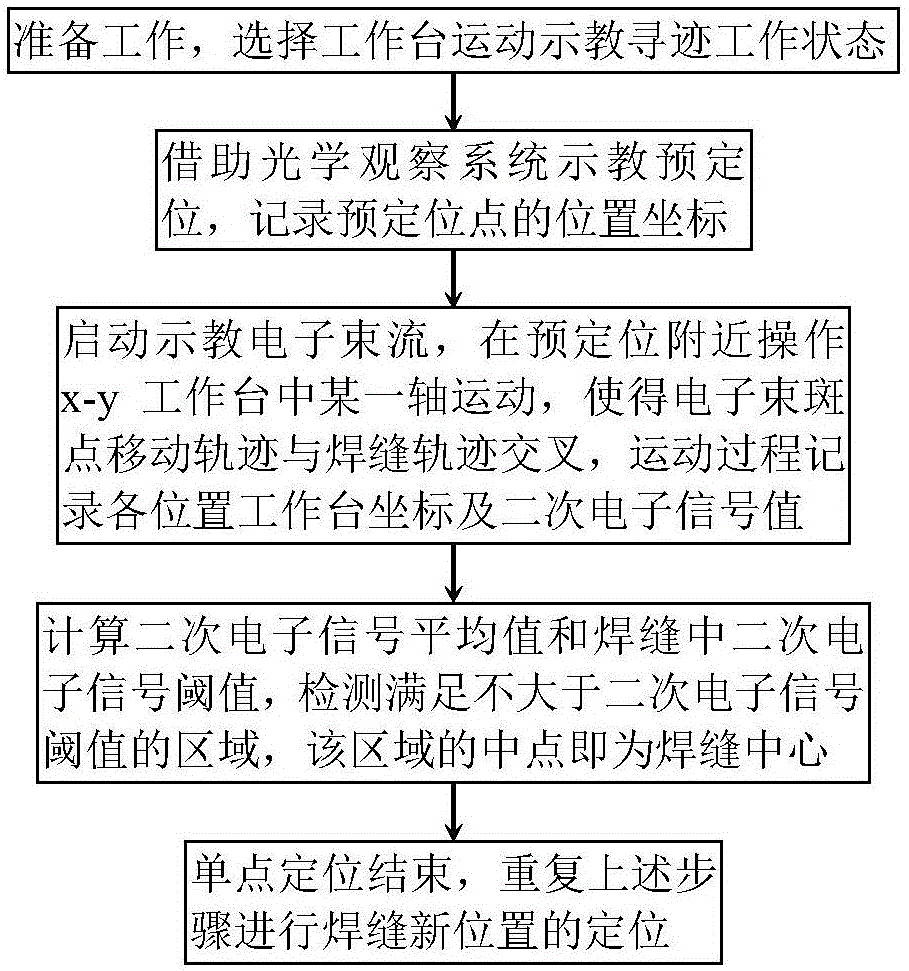

[0075] A method for teaching and tracing of electron beam welding seams based on table motion welding realized by the above system, such as image 3 As shown, it specifically includes the following steps:

[0076] The first step: preparation work.

[0077] ① Place the weldment 11 in the vacuum working chamber 7 .

[0078] ②Close the door of the studio, start the vacuum unit to exhaust the electron gun 6 chamber and the vacuum studio 7.

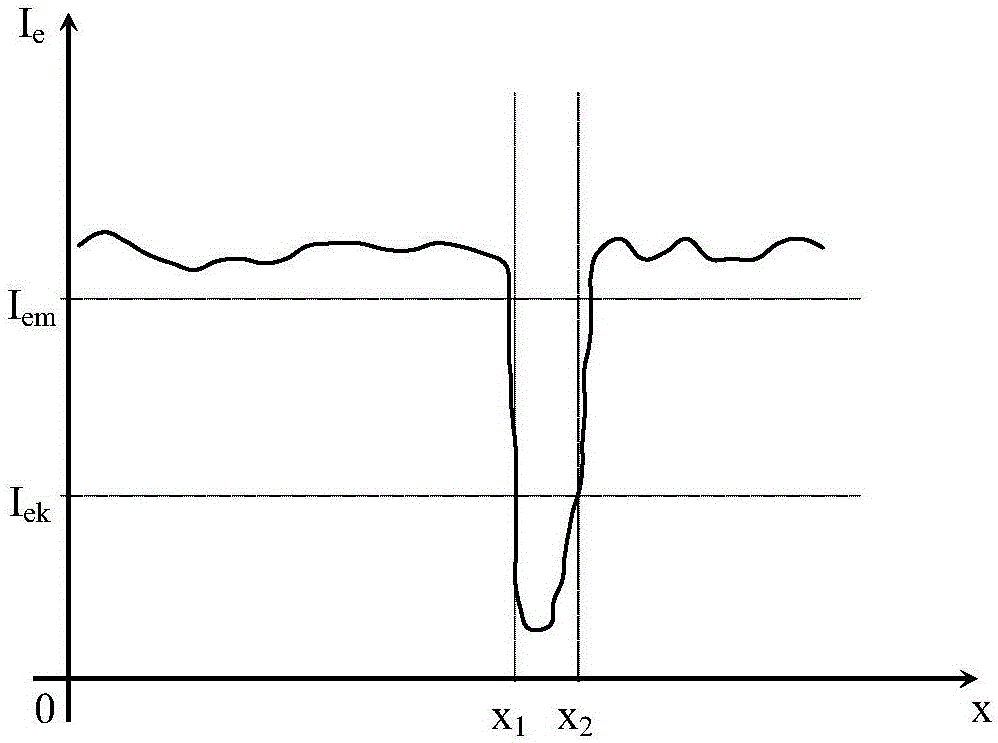

[0079] ③Setting parameters: acceleration voltage U a Set according to the requirements of the working voltage, generally the rated voltage; teach the electron beam current I b The value range is 0.01~1mA; the value range of the discrete detection moving distance δ is 0.01~0.1mm; the value range of the secondary electronic signal threshold coefficient α is 0.2~0.5.

[0080] ④ After the vacuum conditions of the electron gun chamber 6 and the vacuum chamber 7 are satisfied, select the working state of the workbench movement teaching and traci...

Embodiment 2

[0091] A method for teaching and tracing of electron beam welding seams based on table motion welding realized by the above system, such as image 3 As shown, it specifically includes the following steps:

[0092] The first step: preparation work.

[0093] ① Place the weldment 11 in the vacuum working chamber 7 .

[0094] ②Close the door of the studio, start the vacuum unit to exhaust the electron gun 6 chamber and the vacuum studio 7.

[0095] ③Setting parameters: acceleration voltage U a Set according to the requirements of the working voltage, generally the rated voltage; teach the electron beam current I b The value range is 0.01~1mA; the value range of the discrete detection moving distance δ is 0.01~0.1mm; the value range of the secondary electronic signal threshold coefficient α is 0.2~0.5.

[0096] ④ After the vacuum conditions of the electron gun chamber 6 and the vacuum chamber 7 are satisfied, select the working state of the workbench movement teaching and traci...

Embodiment 3

[0108] A method of teaching and tracing of electron beam welder weld seam based on electron beam partial sweep welding realized by the above system, such as Figure 4 As shown, it specifically includes the following steps:

[0109] The first step: preparation work.

[0110] ① Place the weldment 11 in the vacuum working chamber 7 .

[0111] ②Close the door of the studio, start the vacuum unit to exhaust the electron gun 6 chamber and the vacuum studio 7.

[0112] ③Setting parameters: acceleration voltage U a Set according to the requirements of the working voltage, generally the rated voltage; teach the electron beam current I b The value range is 0.01~1mA; the bias sweep current discrete change step distance μ is set as the minimum resolution value of 1 bias sweep current digital setting; the value range of the secondary electronic signal threshold coefficient β is 0.2~0.5.

[0113] ④ After the vacuum conditions of the electron gun chamber 6 and the vacuum chamber 7 are sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com