Novel rolling head

A rolling head and rolling technology, applied in the field of rolling head, can solve problems such as increased error, increased error in workpiece processing, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

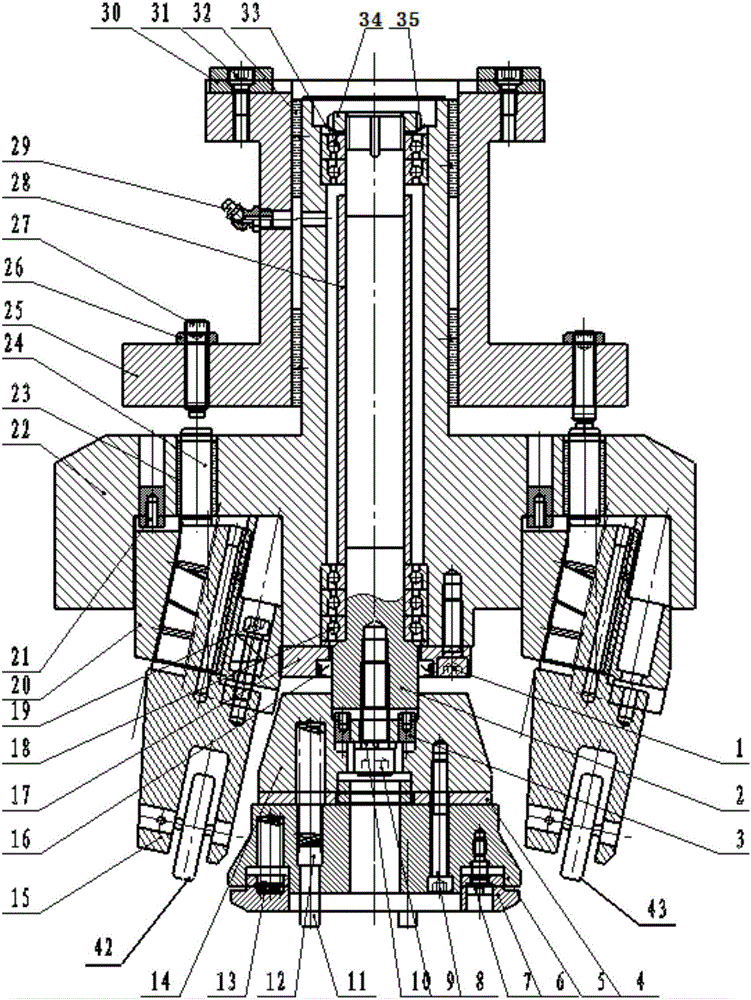

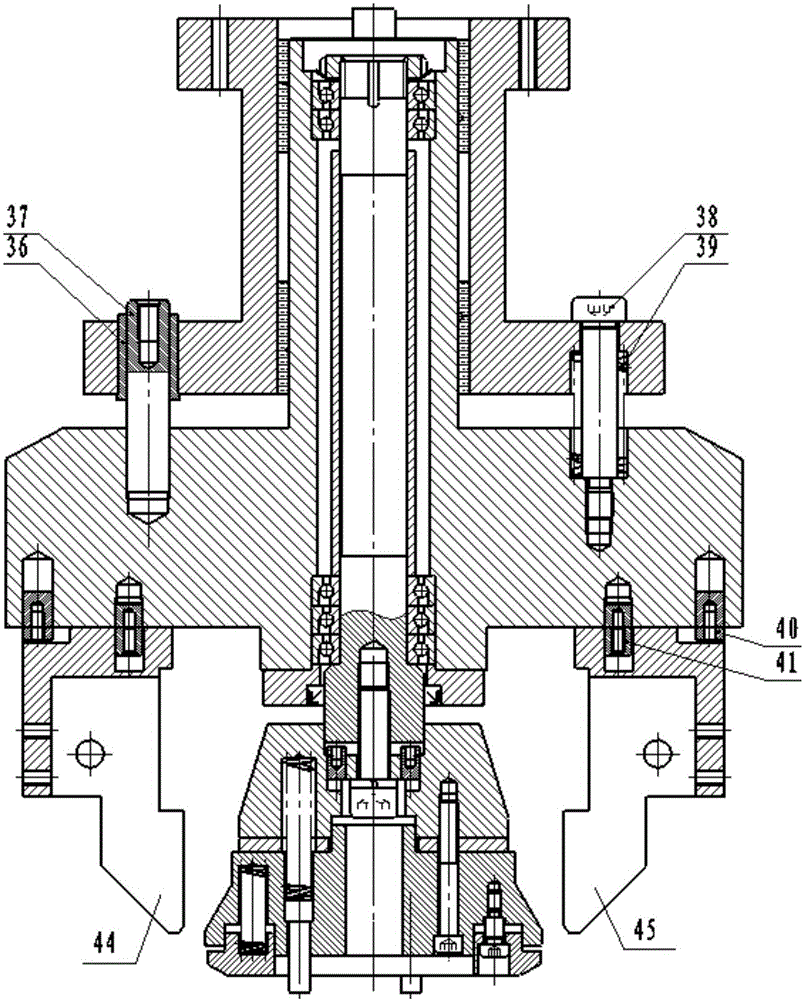

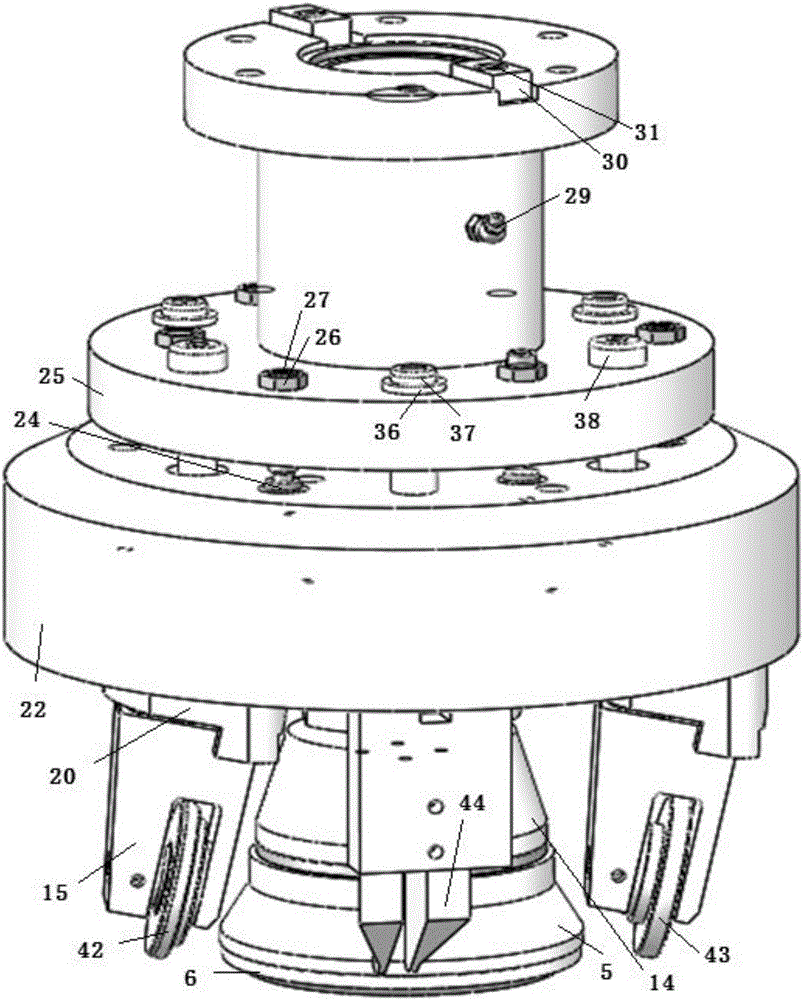

[0028] see figure 1 with image 3 Shown:

[0029] Compression part: Three hexagon socket head cap screws arranged in the circumferential direction fix the triangular pad 17 on the rolling lower body 22 to ensure that the three angular contact ball bearings 18 do not fall off, and at the same time block the central shaft 2 so as not to loosen. Two square round keys 2 3 are installed in the large end slot of the central shaft 2, and the lower end is stuck in the two holes of the pressing disc seat 14, then screw on the hexagon socket head cap screw and add the spring washer 10 to make the center The shaft 2 and the compression disc seat 14 can not move relative to each other in the circumferential direction and the axial direction, so that it can be lowered accurately; The position between the workpieces is convenient for turning down and rolling in the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com