Preparation method for table press

A desktop press and machine body technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of complicated press methods and low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

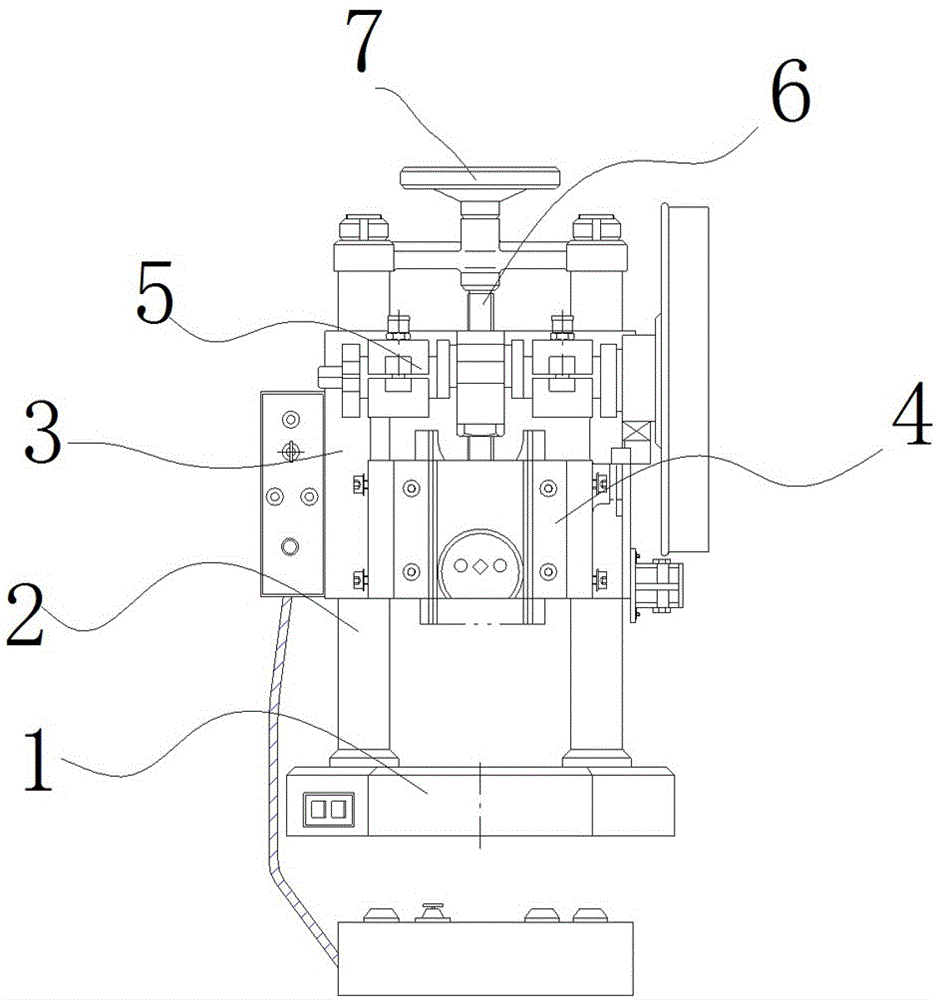

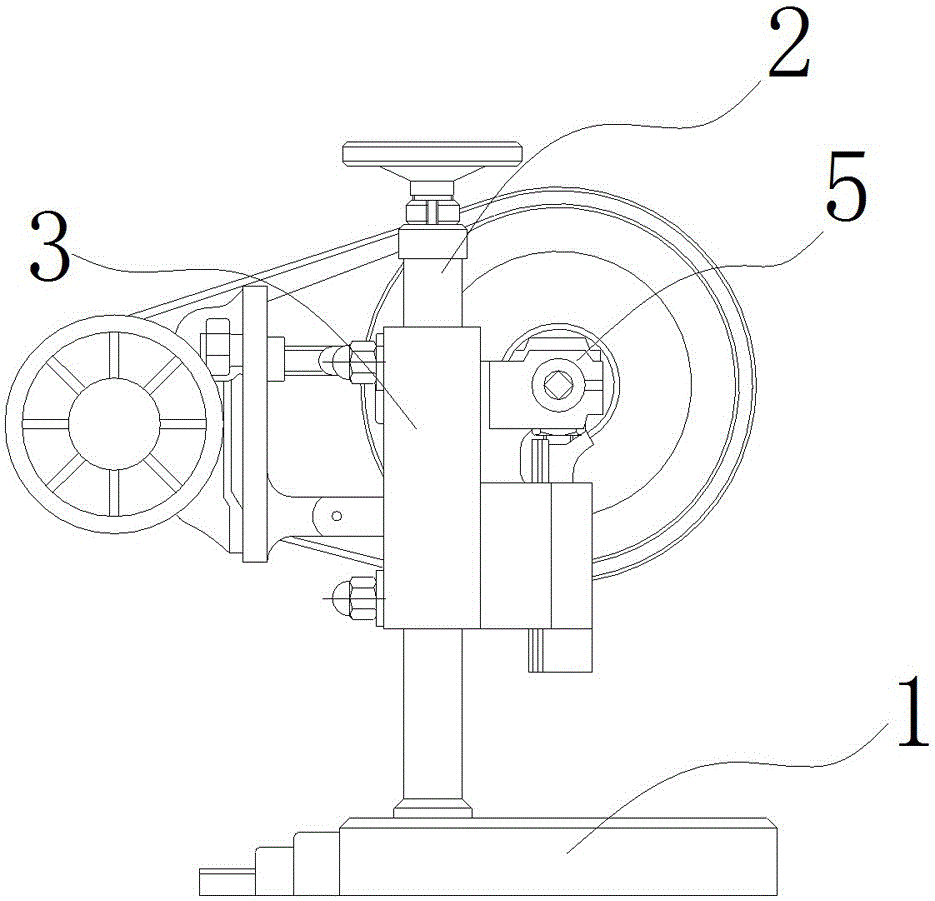

[0222] Embodiment 1: as figure 1 and figure 2 Shown, a kind of preparation method of desktop press is carried out in the following steps:

[0223] (1) Structural composition:

[0224] Including a workbench 1, a number of uprights 2 are arranged on the upper part of the workbench 1, and a body 3 is set on the uprights 2. A slider part 4 is arranged in the body 3, and a crankshaft part 5 is arranged on the upper part of the slider part 4. Between the upper parts of the uprights 2 A ball screw 6 is provided, and the top of the ball screw 6 is provided with a handwheel 7. The crankshaft part 5 is linked with the ball screw 6 to move downward, and the ball screw 6 extends into the slider part 4, and the ball screw 6 drives the sliding block. Block part 4 moves up and down;

[0225] (2) Preparation of slider parts:

[0226] 1. Production of slider body:

[0227] The triangular ribs of the slider body need to be wear-resistant, and their precision is corrected by shoveling. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com