rotary dresser

A dresser and rotary drive technology, used in abrasive surface adjustment devices, metal processing equipment, manufacturing tools, etc., can solve the problems of low dressing accuracy of grinding wheel dressers, achieve small backlash, high transmission accuracy, and ensure dressing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

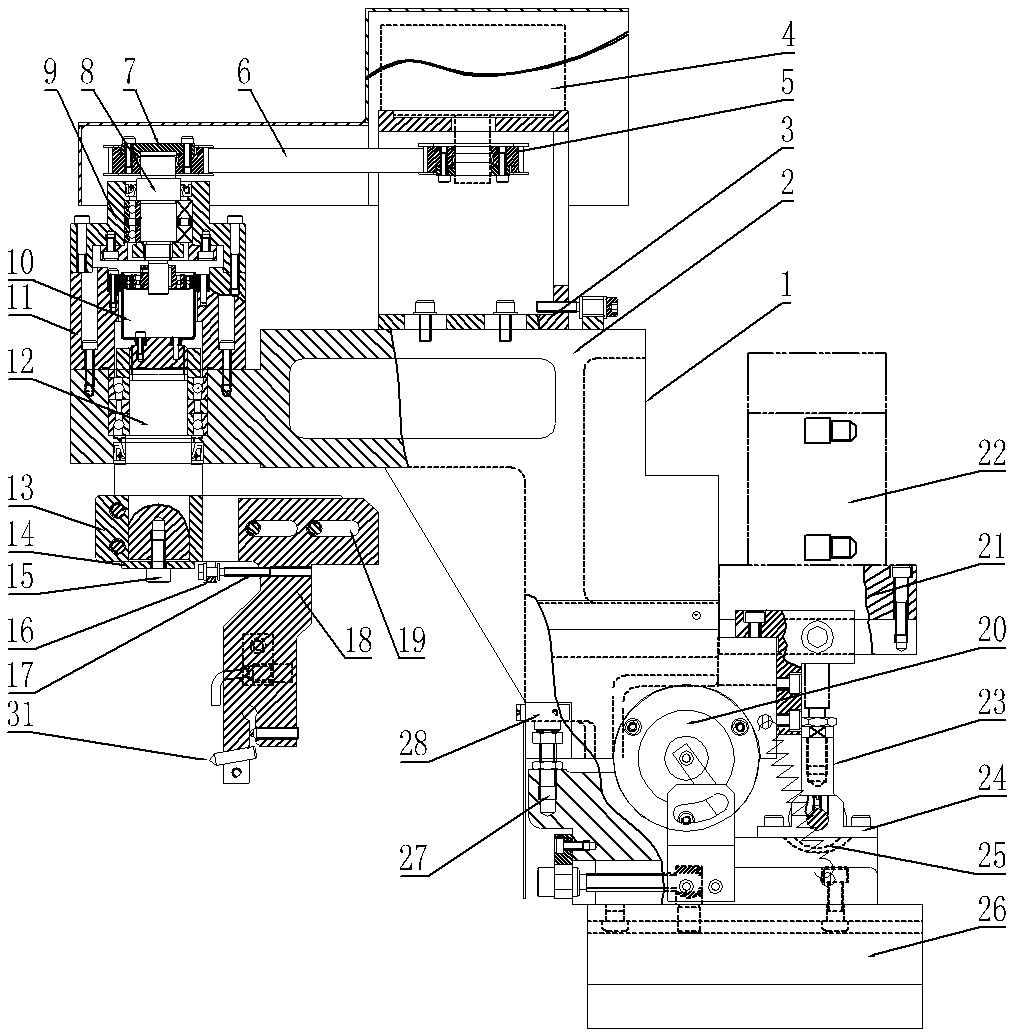

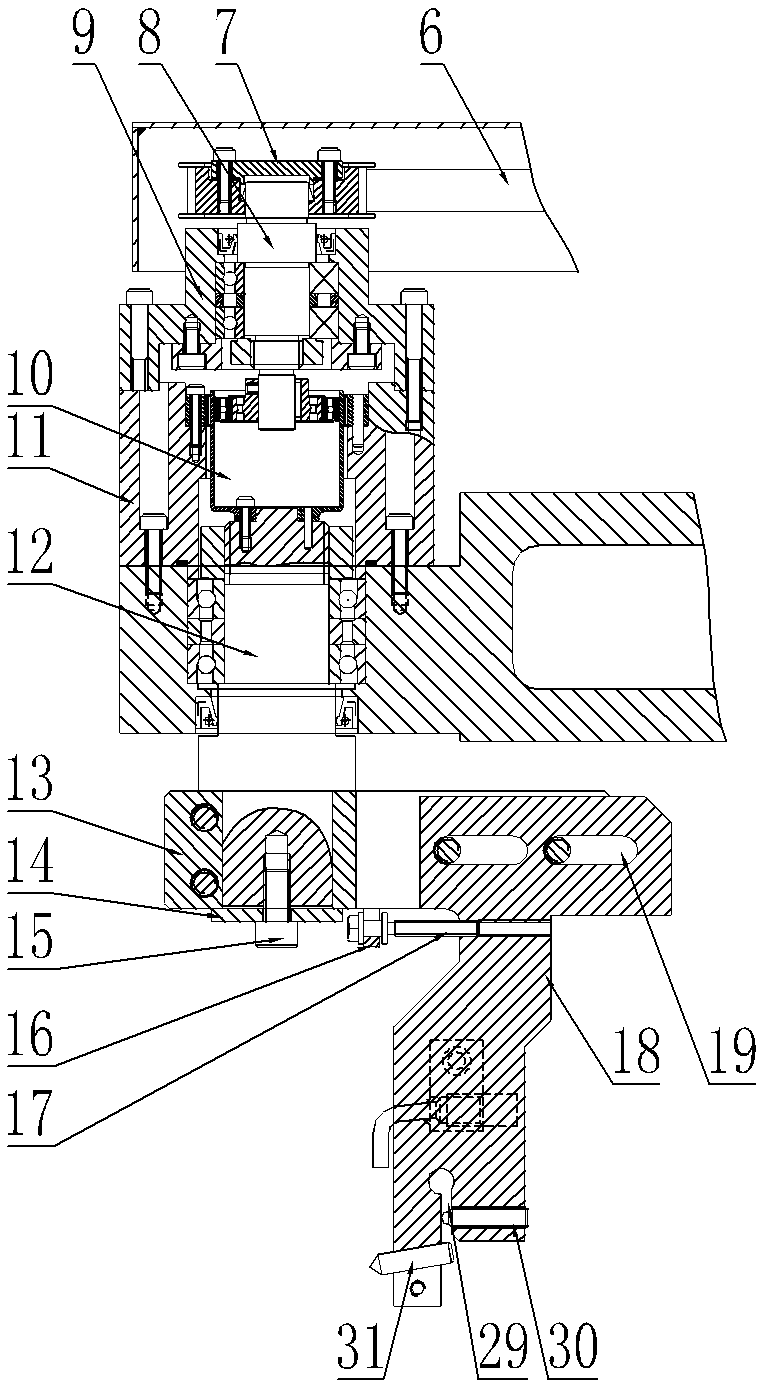

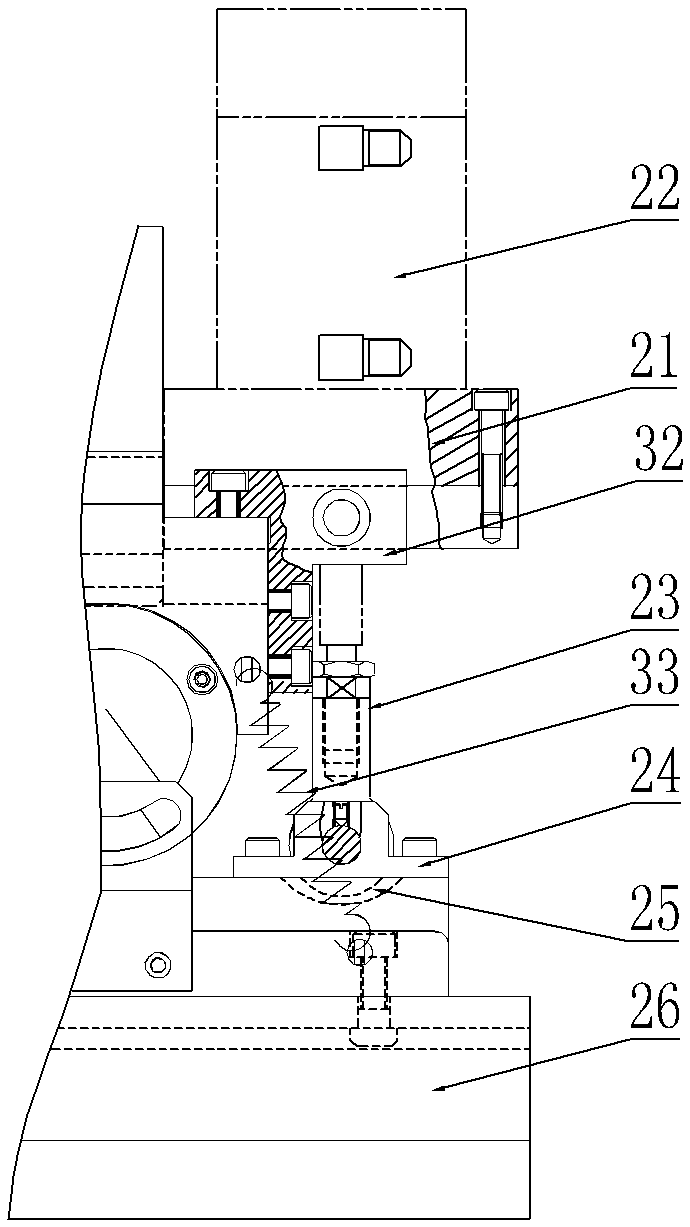

[0019] Such as Figure 1~Figure 3 Shown, it comprises diamond pen 31, fork 18, frame 1 and rotary driving device, and diamond pen is fixed on the fork 18, and rotary driving device is used to drive fork 18 to rotate, and rotary driving device comprises servomotor 4, the first A main shaft 8, a harmonic reducer 10, a second main shaft 12 and a toothed belt 6;

[0020] The upper end of the frame 1 is provided with a support arm 2, the left end of the support arm 2 is fixed with a harmonic reducer seat 11, the upper part of the harmonic reducer 10 seat is fixed with a bearing seat 9, and the harmonic reducer 10 is fixed on the harmonic reducer In the seat 11, the first main shaft 8 is supported on the bearing seat 9 and connected to the input end of the harmonic reducer, and the second main shaft 12 runs through the left end of the support arm and is connected to the output end of the harmonic reducer. The right end of the support arm 2 is fixed with a servo motor base 3, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com