Printing device of sticky printing machine

A technology for printing devices and offset printing machines, applied in printing machines, rotary printing machines, gravure rotary printing machines, etc., can solve problems such as unsuitable printing devices and complex structures, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

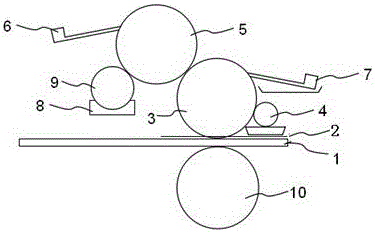

[0017] This embodiment: as figure 1 As shown, a printing device of a self-adhesive printing machine includes a conveying table 1, on which a flat printed matter 2 is arranged, and the printed matter 2 is rotated and crimped to a rubber cylinder 3, and the outer circumference of the rubber cylinder 3 has one end The radial surface is connected to the cleaning roller 4, and the other end of the outer circumference of the rubber cylinder 3 is radially connected to the gravure cylinder 5, and the outer peripheral surface of the gravure cylinder 5 is rollingly connected to the knife head of the gravure cylinder scraper 6, and the rubber cylinder 3 The outer peripheral surface is rollingly connected to the squeegee 7 of the rubber cylinder, and the outer peripheral surface of the gravure cylinder 5 radially faces the ink transfer roller 9 provided with the ink groove 8 at the bottom.

[0018] Several grooves are distributed on the outer peripheral surface of the gravure cylinder 5 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap