Manufacturing method and structure of carbon fiber wheel rim

A manufacturing method and carbon fiber technology, which are applied in the directions of rims, transportation and packaging, vehicle parts, etc., can solve the problem of insignificant effect of overall strength, and achieve the effect of convenient covering and positioning, reducing the number of layers, and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the technical content used in the present invention, the purpose of the invention and the effect achieved more complete and clear disclosure, it is now described in detail below, and please also refer to the disclosed drawings and figure numbers:

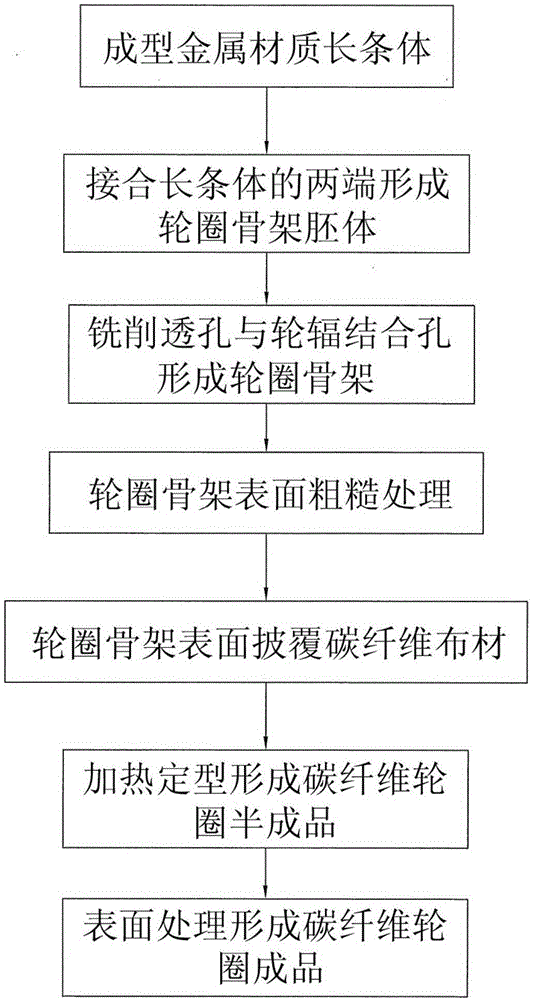

[0058] Please see figure 1 , which is a schematic diagram of the manufacturing process of a preferred embodiment of the manufacturing method of the carbon fiber rim of the present invention. The manufacture method of carbon fiber rim of the present invention, its step comprises:

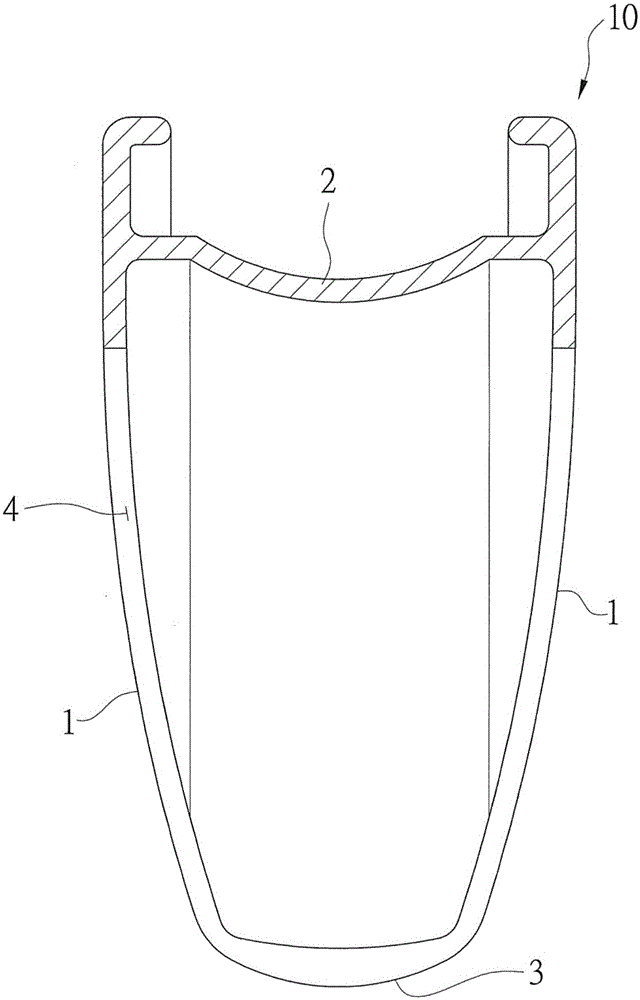

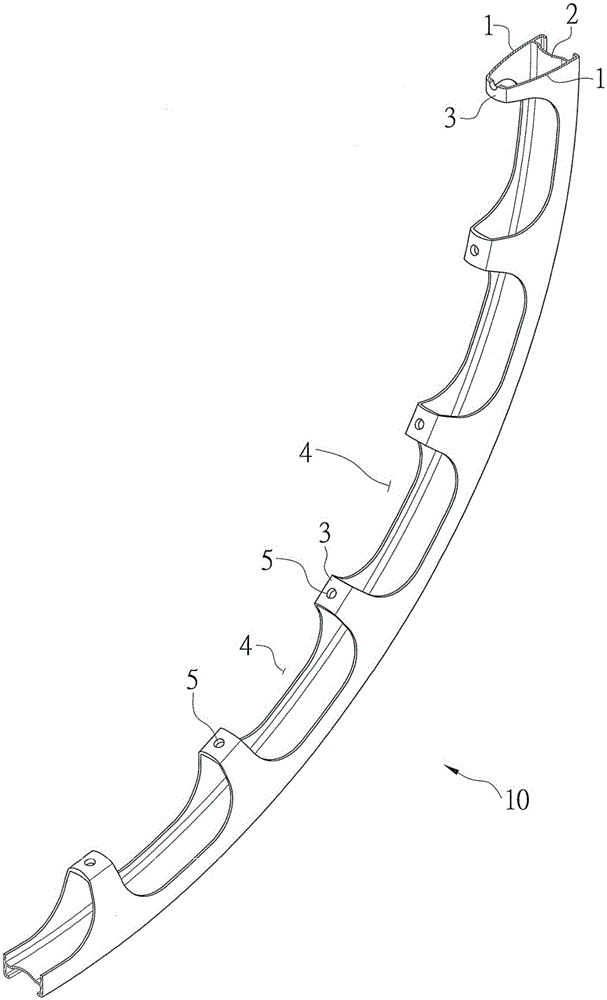

[0059] A. Forming a long strip of metal material, heating the metal substrate to the plastic temperature and then extruding to obtain a long strip of the desired shape (please refer to the following figure 2 ), the elongated body includes two side walls 1, a connecting wall 2 connected between the opposite end faces of the two side walls 1, and an inner ring wall 3 connected between the radial inner edges of the two side walls 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com