Launching system of small parachute

A launch system and parachute technology, applied in the field of small parachute safety landing equipment, can solve the problems of poor launcher stability, slow response, and reduced safety performance of spring-powered parachutes, so as to ensure the pass rate, strong effectiveness, and prevent entanglement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

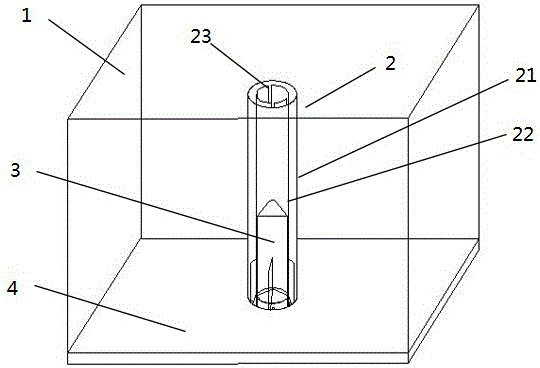

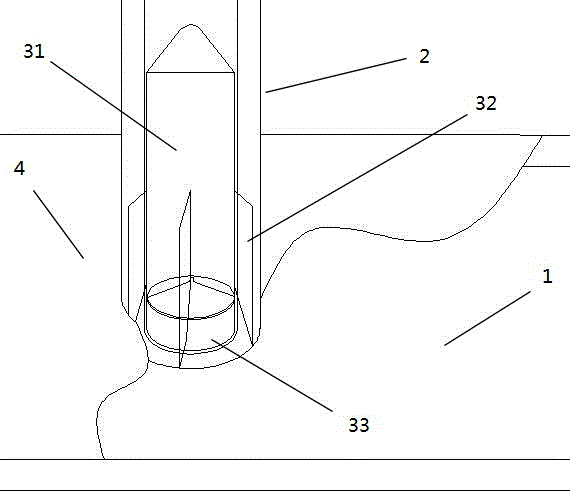

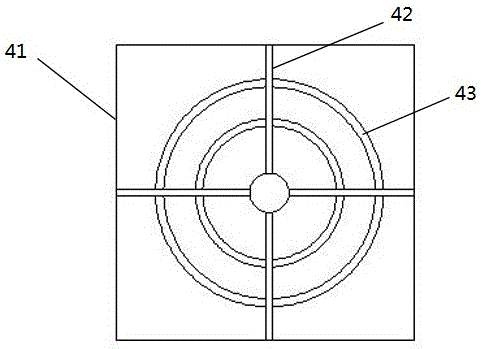

[0053] Embodiment 1: a launch system of a small parachute, characterized in that, the launch system includes a launch tube 2, a casing 1 and a launcher 3; the launch tube 2 is arranged in the casing 1; the launch The launcher 3 is arranged in the launcher 2; the launcher 3 includes a projectile 31 and an igniter 33; the igniter 33 is arranged at the bottom of the launcher 2, and the inner diameter of the launcher 2 is equal to the outer diameter of the igniter 33 The projectile 31 is arranged directly above the igniter 33; the outer diameter of the projectile 31 is equal to the inner diameter of the launch tube 2; the igniter 33 is used to ignite the projectile 31; the projectile 31 After the igniter 33 is ignited, the launch tube 2 can be ejected, and the launch tube 2 is used to pull out the parachute; at least three guide fins 32 are symmetrically arranged on the side wall of the launch body 31; There are empennage slots 23 that are identical in number and matched with the ...

Embodiment 2

[0055] Embodiment 2: a launch system of a small parachute, characterized in that, the launch system includes a launch tube 2, a casing 1 and a launcher 3; the launch tube 2 is arranged in the casing 1; the launch The launcher 3 is arranged in the launcher 2; the launcher 3 includes a projectile 31 and an igniter 33; the igniter 33 is arranged at the bottom of the launcher 2, and the inner diameter of the launcher 2 is equal to the outer diameter of the igniter 33 The projectile 31 is arranged directly above the igniter 33; the outer diameter of the projectile 31 is equal to the inner diameter of the launch tube 2; the igniter 33 is used to ignite the projectile 31; the projectile 31 After the igniter 33 is ignited, the launch tube 2 can be ejected, and the launch tube 2 is used to pull out the parachute; at least three guide fins 32 are symmetrically arranged on the side wall of the launch body 31; There are empennage slots 23 that are identical in number and matched with the ...

Embodiment 3

[0057] Embodiment 3: a launch system of a small parachute, characterized in that, the launch system includes a launch tube 2, a casing 1 and a launcher 3; the launch tube 2 is arranged in the casing 1; the launch The launcher 3 is arranged in the launcher 2; the launcher 3 includes a projectile 31 and an igniter 33; the igniter 33 is arranged at the bottom of the launcher 2, and the inner diameter of the launcher 2 is equal to the outer diameter of the igniter 33 The projectile 31 is arranged directly above the igniter 33; the outer diameter of the projectile 31 is equal to the inner diameter of the launch tube 2; the igniter 33 is used to ignite the projectile 31; the projectile 31 After the igniter 33 is ignited, the launch tube 2 can be ejected, and the launch tube 2 is used to pull out the parachute; at least three guide fins 32 are symmetrically arranged on the side wall of the launch body 31; There are empennage slots 23 that are identical in number and matched with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap