Bottle supply device used for sample collection and preparation

A technology for supplying bottles and sample bottles, which is applied in the field of bottle supplying devices for sample collection and processing, and can solve the problem of inability to evaluate and calculate the real-time consumption of sample vials, affecting work efficiency and production management, and intelligentizing the bottle supplying device. Low-level problems, to achieve the effects of easy use and maintenance, convenient and fast way of taking bottles, and efficient way of taking bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

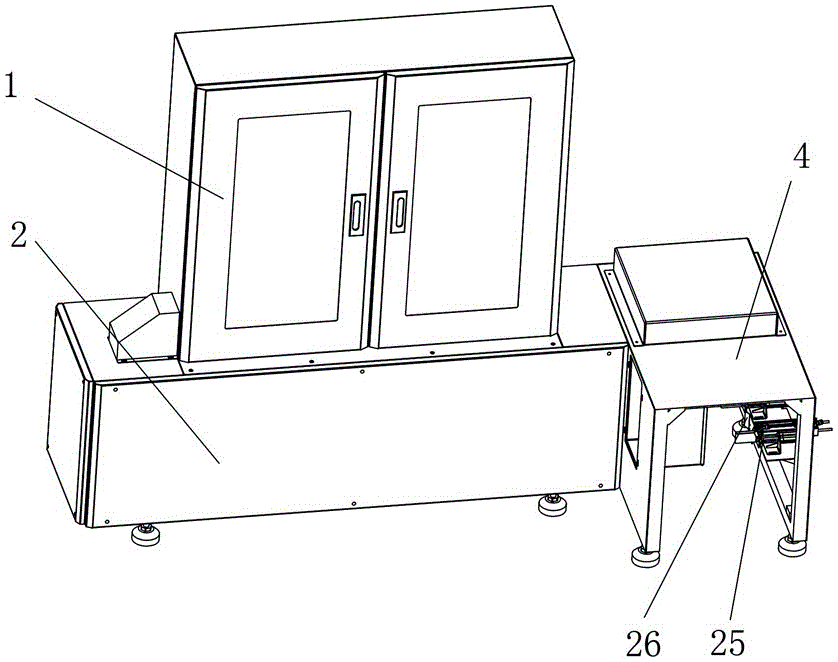

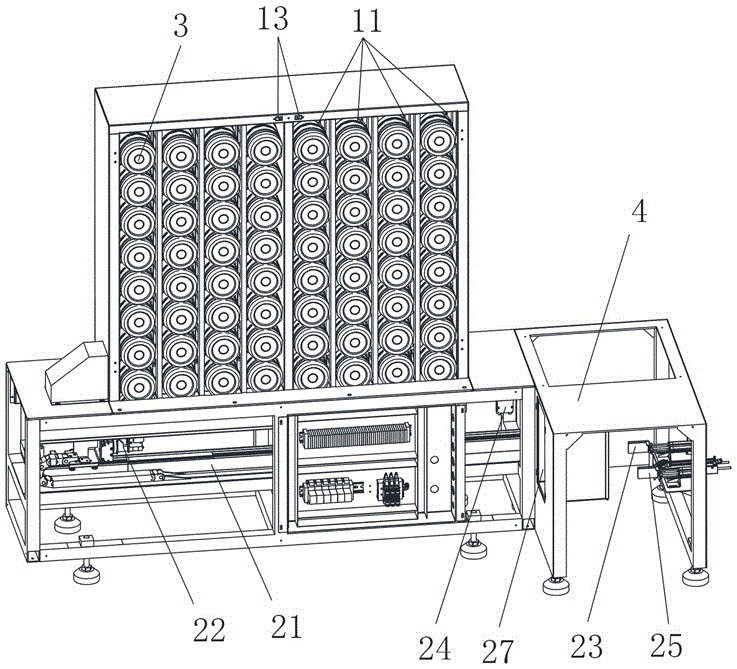

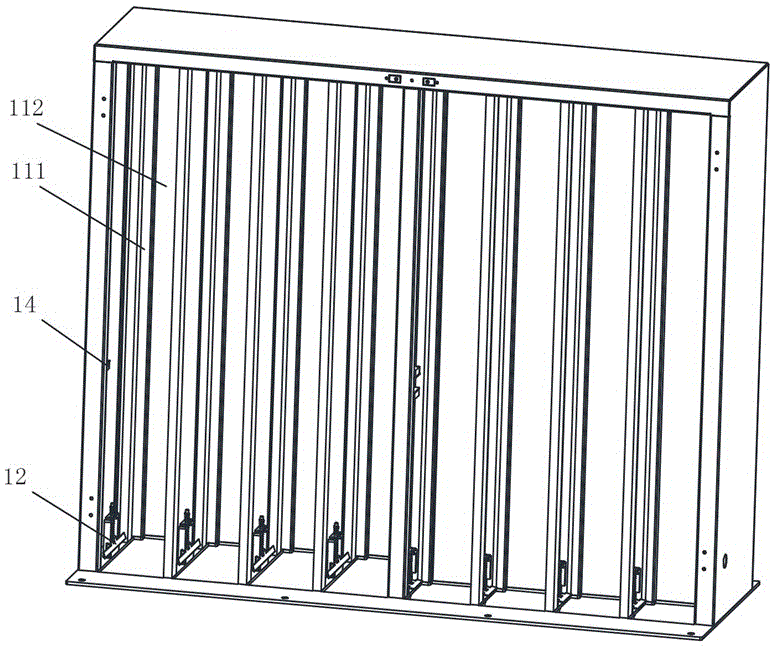

[0039] Such as Figure 1 to Figure 7 As shown, the present invention provides a bottle feeding device for sample collection and processing, comprising a bottle storage cabinet 1 and a bottle fetching and conveying mechanism 2 arranged below the bottle storage cabinet 1. The bottle storage cabinet 1 is provided with multiple rows of vertically parallel The provided storage bottle racks 11 store a plurality of horizontal sample bottles 3 sequentially from bottom to top in each row of storage bottle racks 11 , and the sample bottles 3 in each row are in contact with each other. A bottle stopper switch assembly 12 for blocking the sample bottle 3 from falling downward is provided at the bottle outlet at the bottom of the vertical direction of each column storage bottle grid 11 . One end of the bottle fetching and conveying mechanism 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com