Needling mechanism of single-spindle single-needle-area needling machine

A single-spindle, acupuncture machine technology, applied in the field of acupuncture machines, can solve the problems affecting the quality and output of acupuncture products, vibration and shaking of the acupuncture machine, hidden safety hazards, etc., to achieve low noise and vibration, reduce vibration and The effect of shaking, ensuring quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

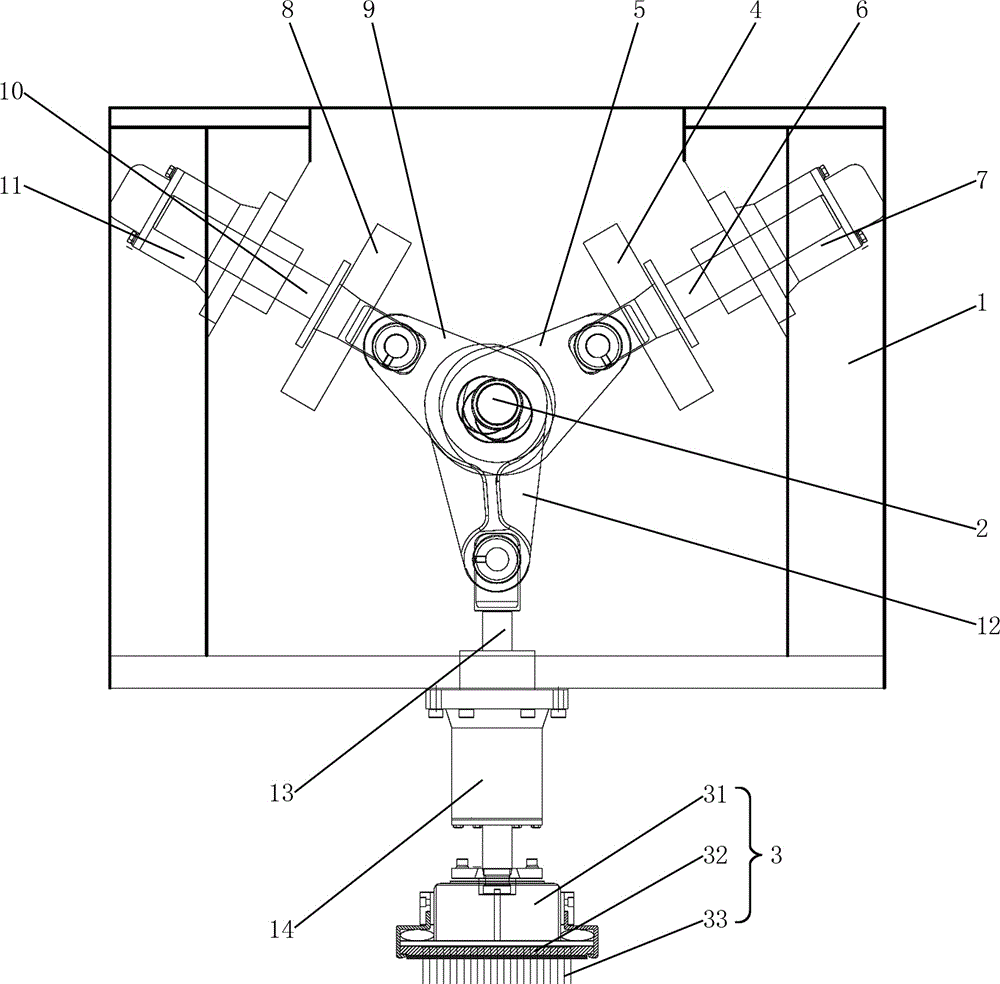

[0020] Such as Figure 1-Figure 3 As shown, the needling mechanism of the single-spindle single-needle zone needling machine includes a frame 1 , a drive shaft assembly 2 and a needling part 3 , and the drive shaft assembly 2 is rotatably mounted on the frame 1 . The transmission shaft assembly 2 is connected with the acupuncture unit 3 through at least one (one in this embodiment) lifting transmission mechanism.

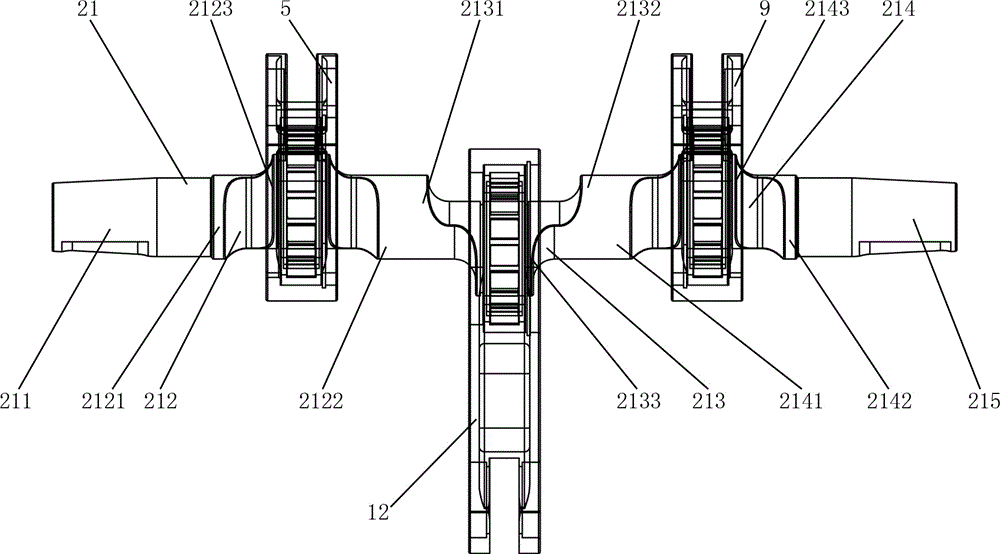

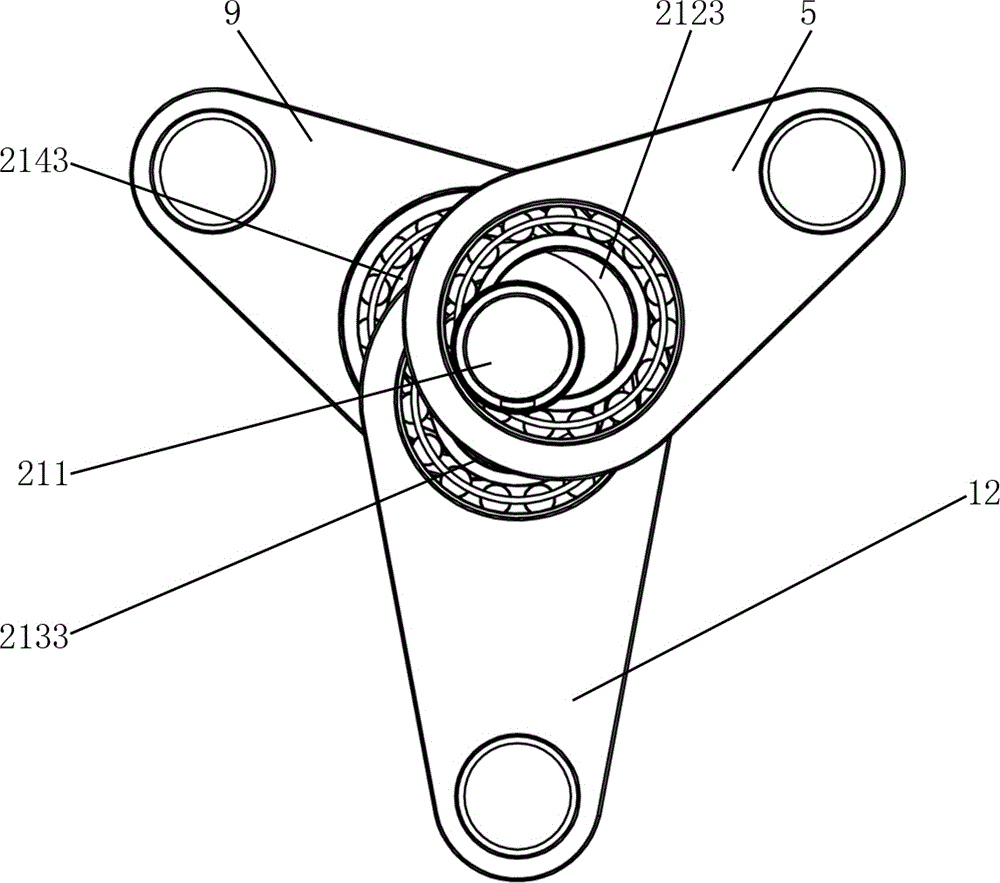

[0021] The transmission shaft assembly 2 includes at least one (one in this embodiment) crankshaft set 21, the crankshaft set 21 has the same number and one-to-one correspondence with the lifting transmission mechanism; the crankshaft set 21 includes a left connecting shaft 211, a first Balance crankshaft 212, acupuncture drive crankshaft 213, second balance crankshaft 214 and right connecting shaft 215; They are respectively arranged on the left side and the right side of the boss 2123, the axes of the two shaft heads 2121, 2122 coincide, the boss 2123 is cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com