Built-in sewing machine winding mechanism

A winding mechanism and sewing machine technology, applied in the direction of bobbin winding in sewing machines, sewing machine components, sewing equipment, etc., can solve the problems of affecting the working efficiency, stability and reliability of sewing machines, affecting the aesthetics of sewing machines, and low degree of automation. Achieve the effects of superior performance, improved work stability and work efficiency, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

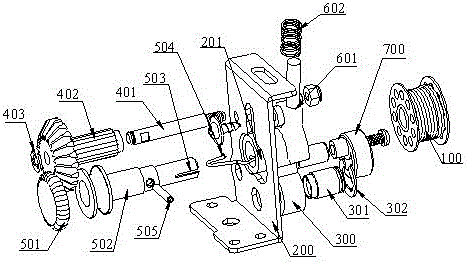

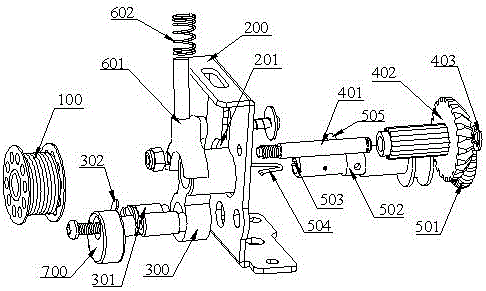

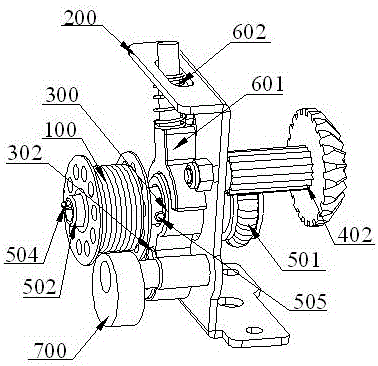

[0020] refer to Figure 1 to Figure 6 , propose an embodiment of a built-in sewing machine winding mechanism of the present invention, the sewing machine includes a casing, a motor transmission mechanism located in the casing, the motor transmission mechanism includes a motor, a main shaft that can rotate with the work of the motor, A driven gear that is set on the main shaft and can rotate with the rotation of the main shaft. The upper end surface of the casing is provided with a storage slot that can accommodate the bobbin 100 at the position corresponding to the position of the driven gear. Simple and practical, reasonable and innovative design.

[0021] The sewing machine winding mechanism of the present invention is built in the casing, the sewing machine winding mechanism can fix the bobbin 100 and can complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com