a cooking system

A technology of hot water washing and speed adjustment, applied in textile and papermaking, textile material processing, textile material carrier processing, etc., can solve the problems of inability to reduce steam usage and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

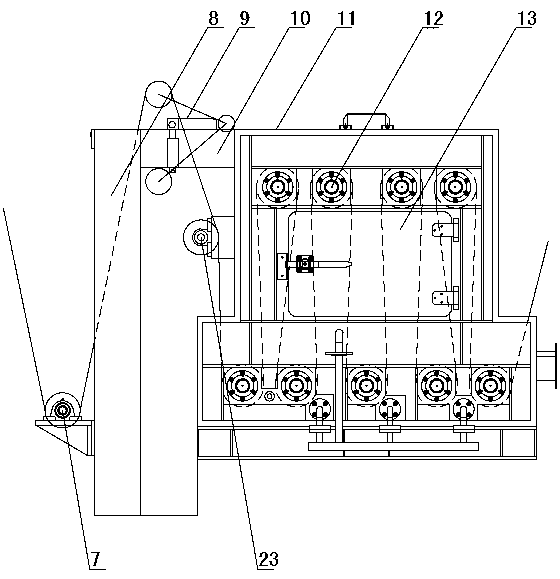

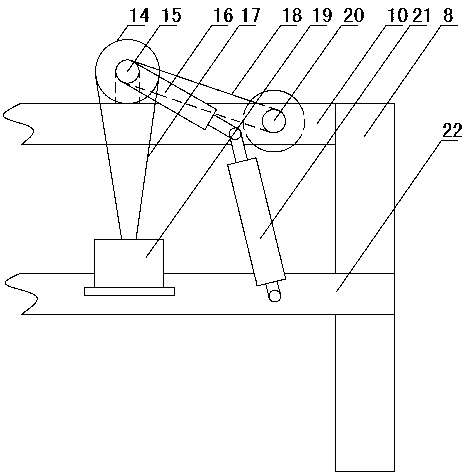

[0027] Figure 1~4 It is the best embodiment of the present invention. Figure 1~5 The present invention will be further explained.

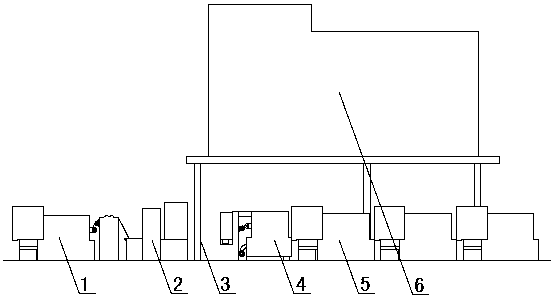

[0028] Such as figure 1 As shown, a scouring system includes a primary hot water washing unit 1, a rolling aid unit 2, and a secondary hot water washing unit 5 arranged in sequence in the salt process, wherein the primary hot water washing unit 1 and the secondary hot water washing unit 5 are both end-to-end There are a plurality of adjacent ones, and the rolling aid unit 2 is arranged at the output port of the primary hot water washing unit 1 at the end. A speed adjusting unit 4 is provided at the output port of the rolling aid unit 2, and a plurality of secondary hot water washing units 5 are sequentially arranged at the output port of the speed adjusting unit 4, and the speed adjusting unit 4 and the secondary hot water washing unit 5 A steaming unit 6 is arranged on the upper side, and the steaming unit 6 is supported by a plurality of support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com