A Concrete Frame Seismic Reinforcement Structure Using Steel Mesh

A technology for strengthening structures and steel mesh, which is applied in the direction of building structure, building types, buildings, etc., can solve problems affecting normal life, achieve convenient construction, solve frictional energy consumption, and improve energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

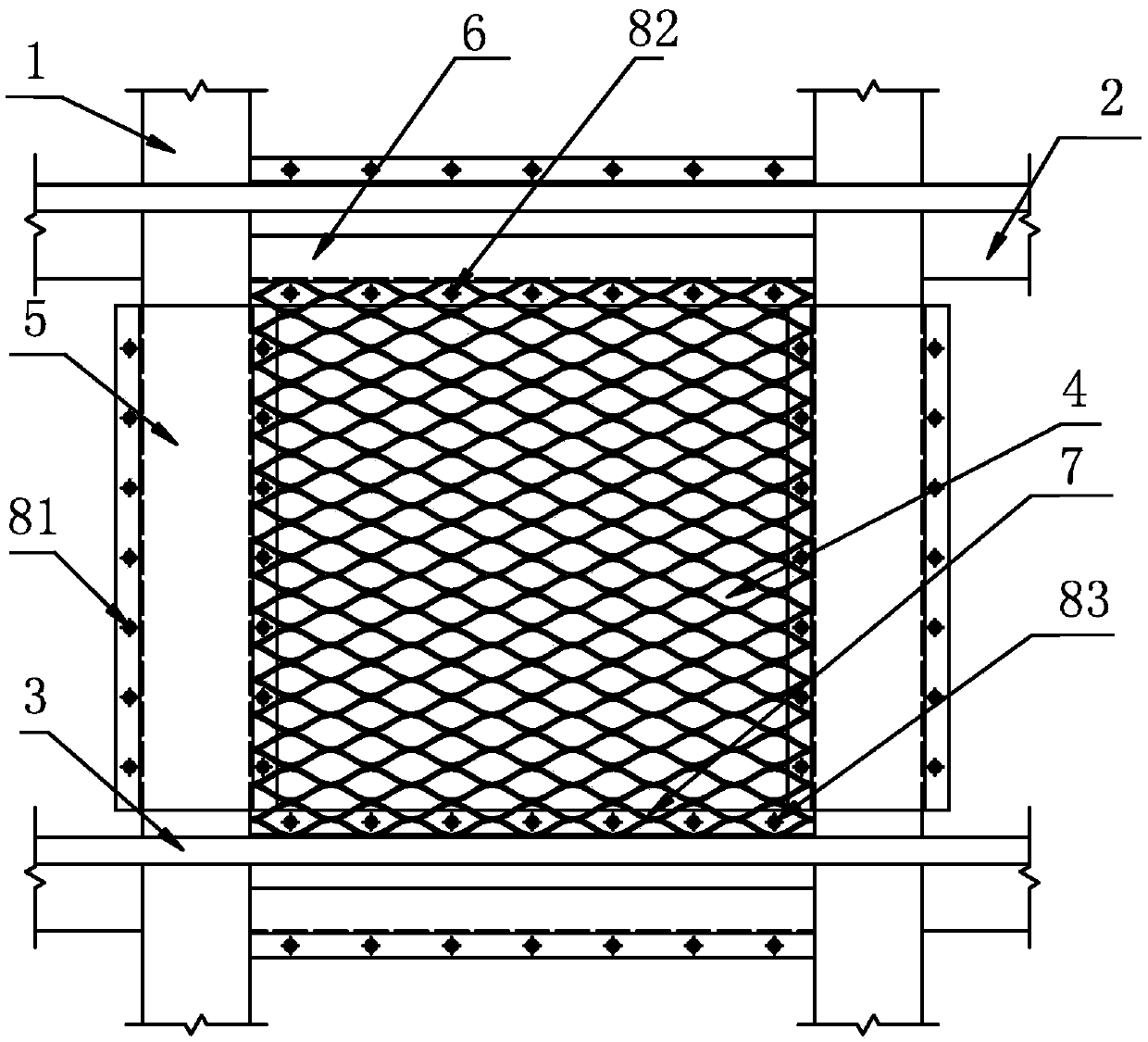

[0024] Such as figure 1 As shown, the present invention proposes a concrete frame anti-seismic reinforcement structure using steel mesh, which consists of frame columns to be reinforced and frame beams to be reinforced to form a concrete frame to be reinforced, and two adjacent frame columns to be reinforced on the same facade and two adjacent frame beams to be reinforced are respectively connected with steel mesh 4, a column restraint kit is provided between the steel mesh 4 and the frame column to be reinforced, and a Features a beam restraint kit and two equilateral angles7.

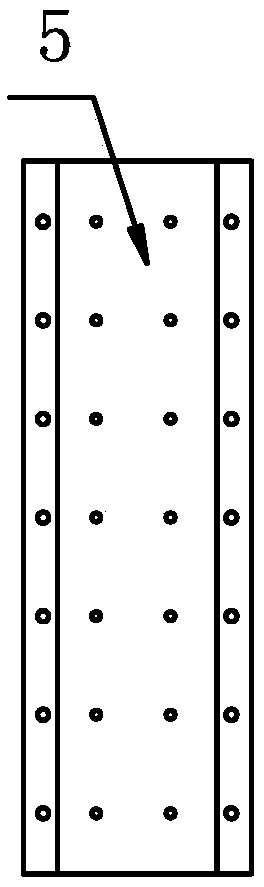

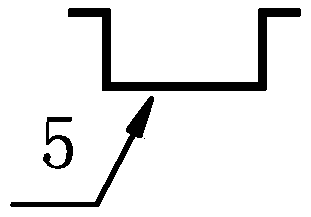

[0025] The column restraint kit includes two semi-enclosed channel steel members 5, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com