Straight pipe structure for underwater anti-clogging and drag reduction

A straight pipe and anti-blocking technology, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as pipe blockage, inner wall wear of pipe fittings, and large water flow resistance of ordinary pipe fittings, so as to reduce resistance and avoid The effect of hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

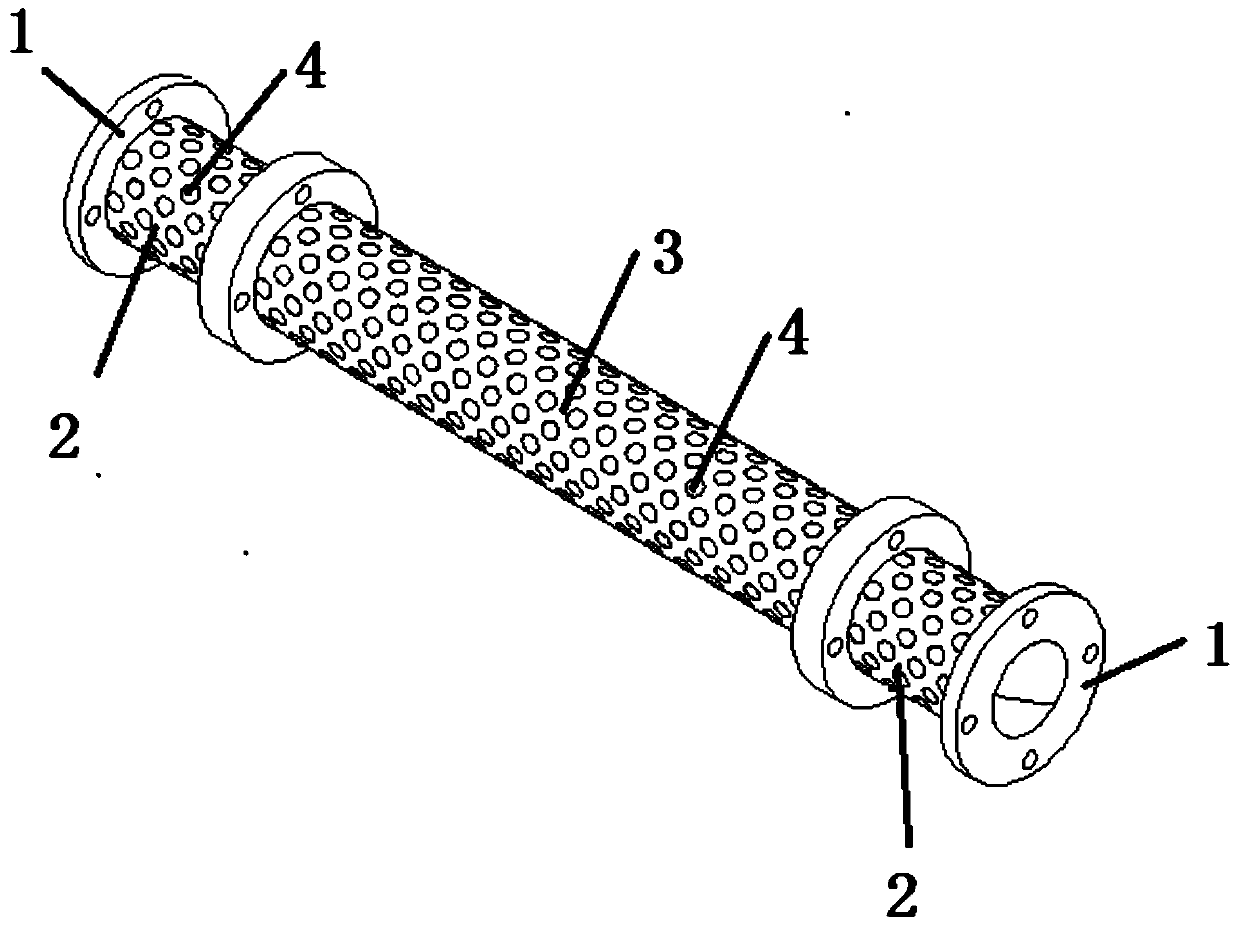

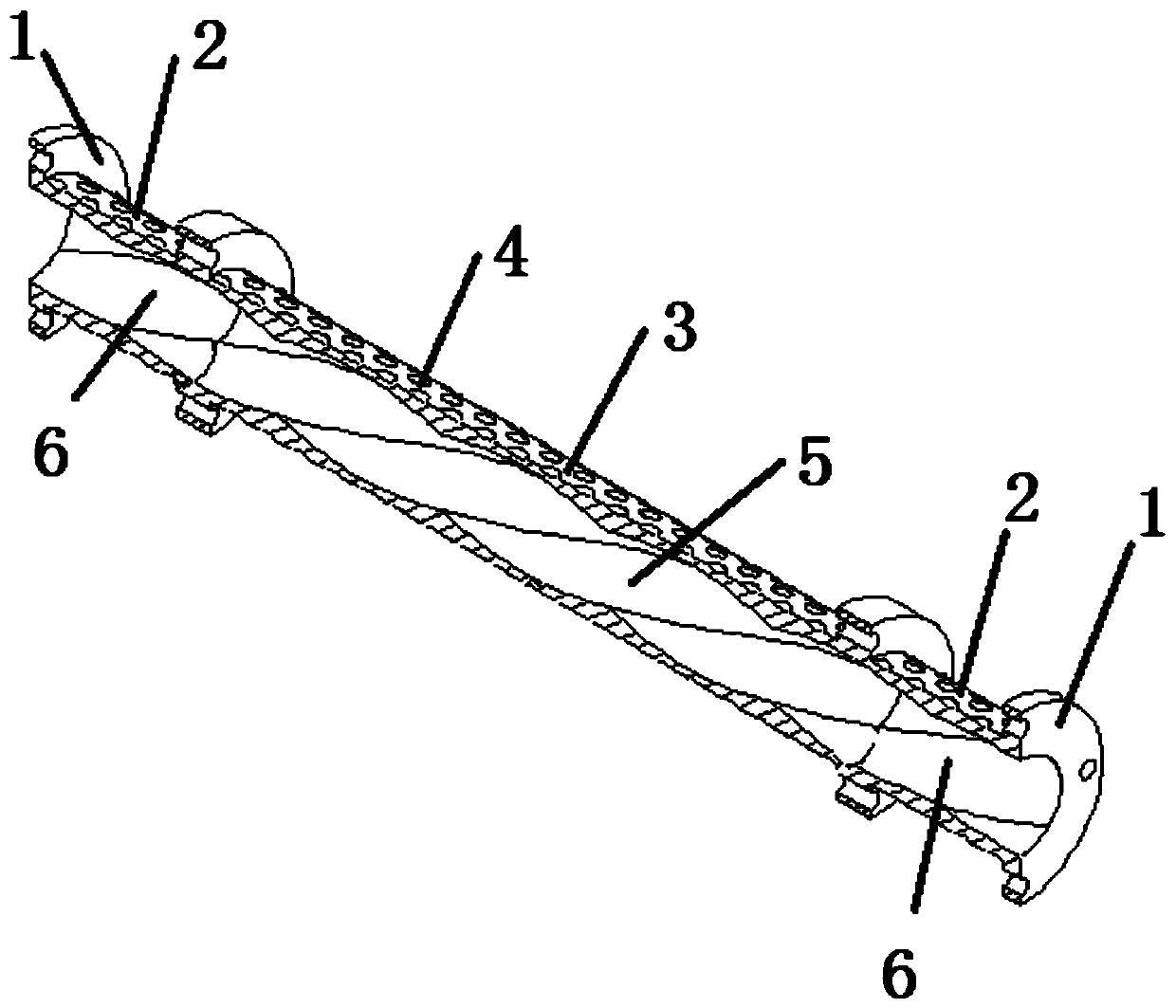

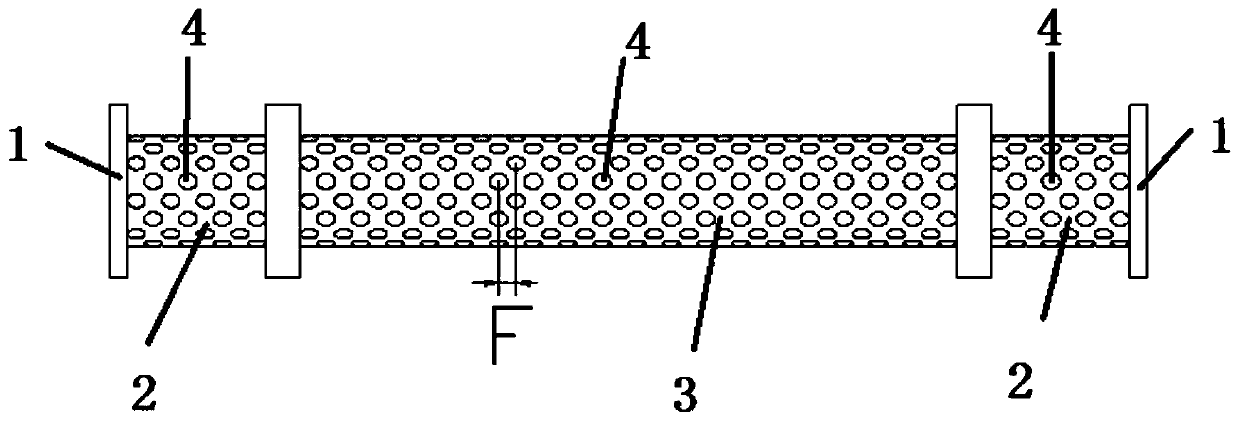

[0023] As shown in the accompanying drawings, a straight pipe structure for underwater anti-blocking and drag reduction includes a main pipe section 3 with a plurality of main spiral grooves 5 inside the flow channel, and two rotary pipes respectively arranged at both ends of the main pipe section 3. The connecting section 2 , the main pipe section 3 and the connecting section 2 are respectively provided with a plurality of pits 4 on their outer surfaces. A plurality of dimples 4 are alternately and evenly distributed on the outer surfaces of the main pipe section 3 and the transition section 2 . The hydraulic diameter of the transition section 2 is equal to the hydraulic diameter D of the main pipe section 3 , and correspondingly, the outer diameter of the transition section 2 is also equal to the outer diameter E of the main pipe section 3 .

[0024] The transition section 2 has a gradual spiral groove 6 connected to the main spiral groove 5, and the gradual spiral groove 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com