Underwater dirt cutting and pulverizing machine suitable for water conservancy and hydropower projects

A water conservancy and hydropower, cutting and crushing technology, which is applied in water conservancy projects, sea area projects, artificial waterways, etc., can solve the problems of no pollution cleaning measures, and achieve the effect of eliminating salvage, reducing project operating costs, and quickly and efficiently cleaning pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

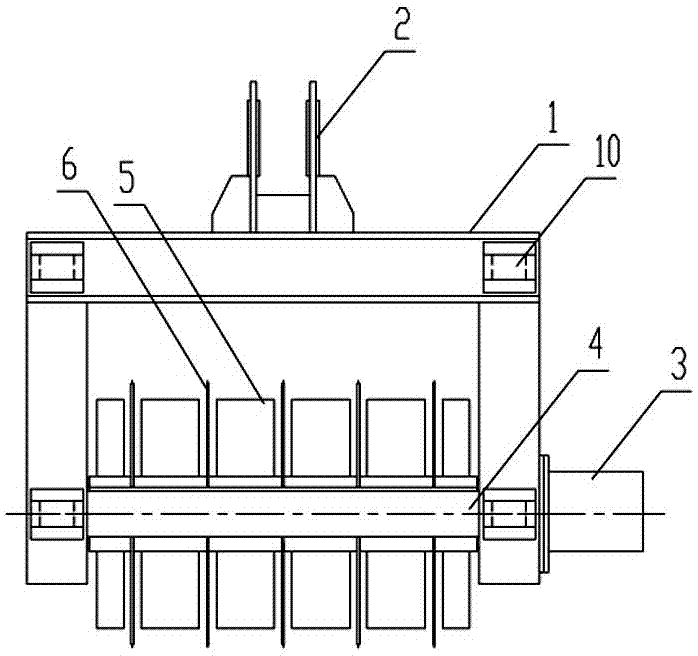

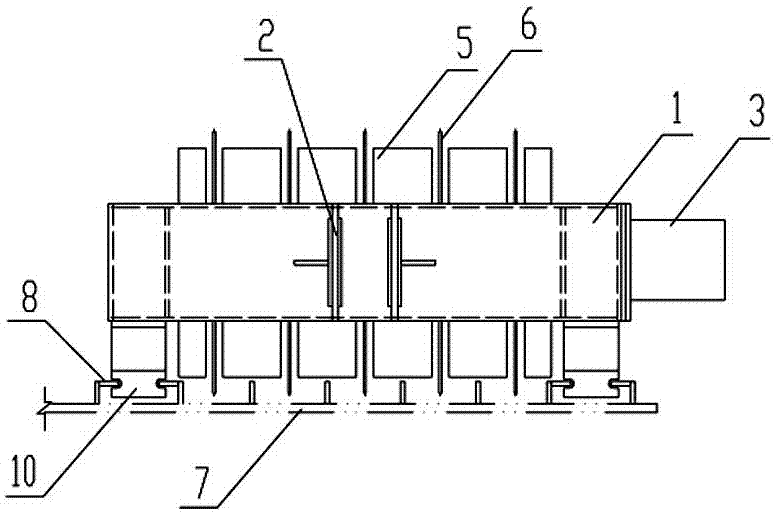

[0017] Such as figure 1 , 2 , 5, 6, and 7, the underwater dirt cutting and pulverizing machine suitable for water conservancy and hydropower projects according to the present invention includes a "gate" sub-frame 1, and lifting lugs arranged on the crossbeam of the "gate" sub-frame 1 2. A cutting and crushing mechanism is provided on the "gate" sub-frame 1; the cutting and crushing mechanism is directly connected to the power shaft 4 driven by the underwater motor 3, and the power shaft 4 is horizontally arranged on the left side of the "gate" sub-frame through the bearing body. Between the columns on the right side, a plurality of rake wheels 5 are fixedly set on the power shaft 4 at intervals, and saw blades 6 are fixedly set on the power shaft 4 between adjacent rake wheels 5, and the diameter of the saw blade 6 is larger than that of the rake wheels 5. Diameter; Be positioned at the left and right side column of " door " sub-shaped frame 1 and be respectively fixed with t...

Embodiment 2

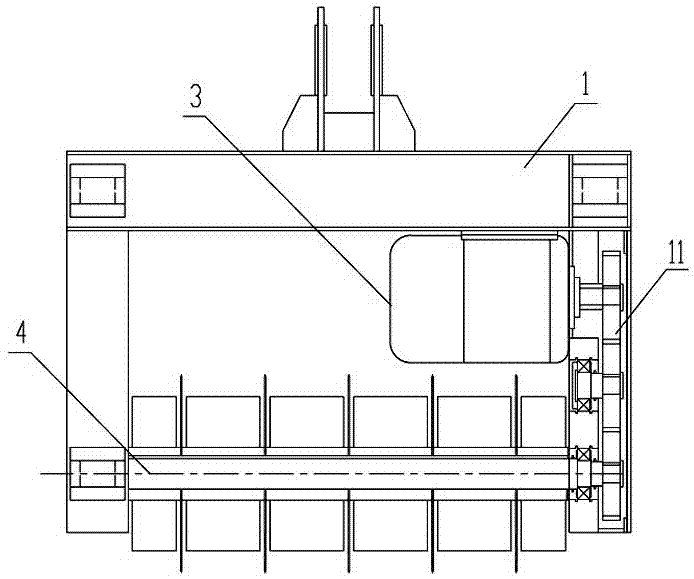

[0019] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the underwater motor 3 of the cutting and crushing mechanism is connected with the power shaft 4 through the sprocket drive mechanism 11; When the direct connection is not suitable due to the influence of volume, the torque of the underwater motor 3 is transmitted to the power shaft 4 through the transmission mechanism 11 . The transmission mechanism can be in various forms such as gears, sprockets, and belt pulley transmissions.

Embodiment 3

[0021] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that an intermediate column 12 is fixed vertically downwards at the crossbeam middle part of the "door" sub-shaped frame 1, and between the left and right sides of the intermediate column 12 and the "door" sub-shaped frame 1. A set of cutting and crushing mechanisms are respectively arranged between the columns on both sides, and each set of cutting and crushing mechanisms is the same as that of Embodiment 2, that is, the underwater motor 3 of each cutting and crushing mechanism is connected with the power shaft 4 through the transmission mechanism 11 ; This embodiment is mainly applicable to the cutting and crushing of the underwater dirt of the trash rack with a large-span structure.

[0022] The working principle of the present invention is briefly described as follows:

[0023] When the dirt piled up in front of the trash rack 7 needs to be cleaned up, the hoisting equipment lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com