Optical collector for automotive dipped headlight module

A concentrator and low beam technology, applied in the field of concentrators, can solve the problems of high cost, large module space, and the concentrator has a single condensing structure, etc., and achieves the effect of large margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

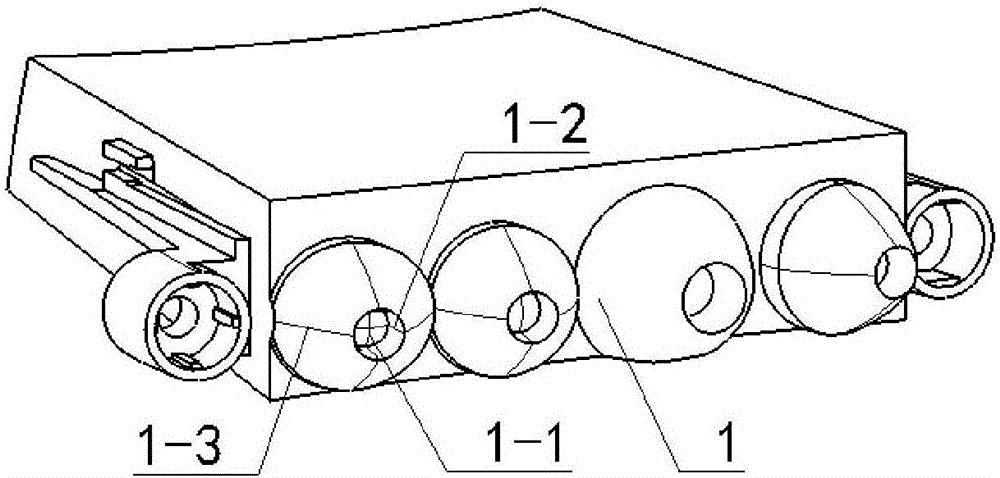

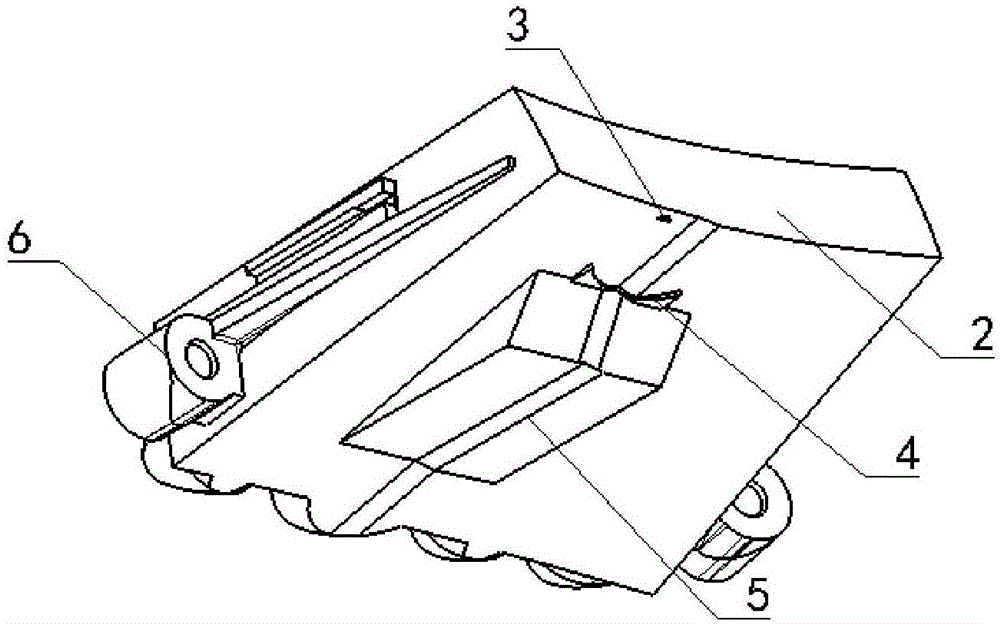

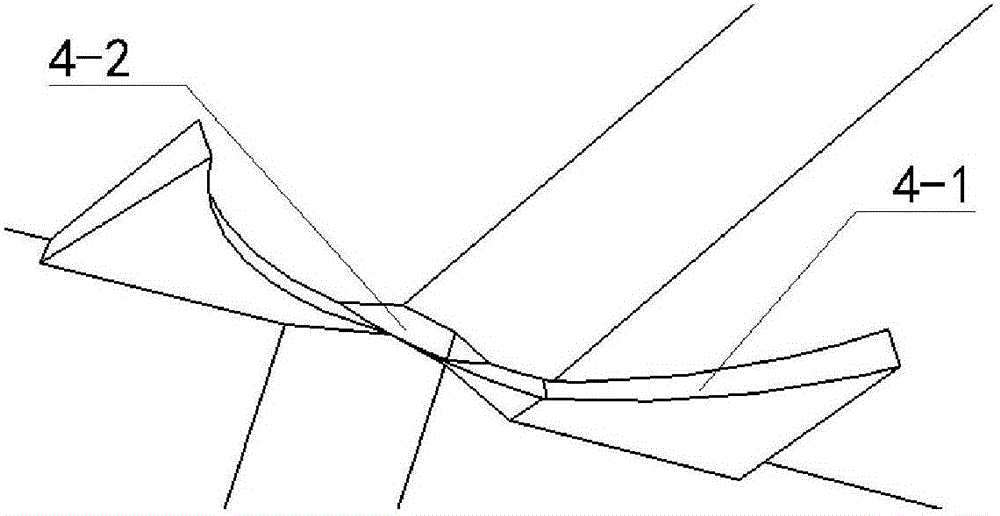

[0094] Such as figure 1 and2 As shown, the embodiment of the present invention provides a concentrator for a low-beam vehicle lamp module, which is used for the low-beam illumination of an automobile and placed in the headlight of the automobile. The concentrator includes a light concentrating structure 1 , a cutoff line forming structure 2 , a 50L dark region forming structure 3 , a III region forming structure 4 , a SEG10 brightness reducing structure 5 and a concentrator installation structure 6 . The overall size of the concentrator is about 65mm in length, about 50mm in width, and about 10mm in height. The material of the light concentrator is transparent plastic or resin, and the material used in this embodiment is PC with a refractive index of 1.586-1.587.

[0095] The light concentrating structure 1 is arranged at the rear end of the light concentrator, the cut-off line forming structure 2 is arranged at the front end of the light concentrator, the SEG10 brightness r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com