Liquid pre-injection communicating pipe device for hydrostatic leveling instrument, and liquid injection method and measurement method of liquid pre-injection communicating pipe device

A static level and connecting pipe technology, which is applied to measuring devices, measuring inclinations, instruments, etc., can solve problems such as the influence of the installation efficiency of the measurement site, the interference of bubbles on the measurement of the static level, and the inability of the bubbles to be effectively discharged in time. The effect of bubbles on measurement interference, convenient operation and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

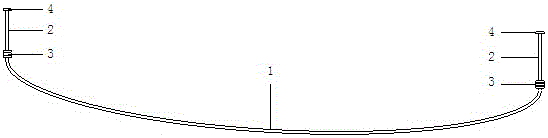

[0033] When pre-filled at the factory, the connecting tube presses figure 1 The sealing section 2 is set and connected with a transparent joint 3; the end of the sealing section 2 is provided with a terminal joint 4.

[0034] In this embodiment, the polyurethane transparent tube 1 is used as the pre-injection liquid connecting pipe section used in the measurement site, and the inner diameter is between 10 and 20 mm. The models of the transparent joint 3 and the end joint 4 are consistent with those of the liquid injection joint 5 of the pre-filled transparent box to facilitate connection.

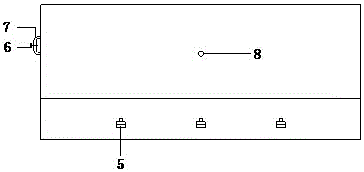

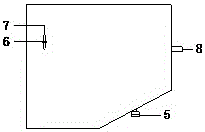

[0035] The pre-fill liquid transparent box of the factory pre-fill liquid is the same as the on-site public liquid tank, such as figure 2 , 3 , 4, and 5.

[0036] Transparent casing box wall 11 selects transparent plastics or plexiglass for use. The transparent box is divided into an upper layer and a lower layer structure, and the top layer of the upper layer is open. Between the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com