Electrode connection structure of ultrasonic sensor

A technology for connecting structures and sensors, which is applied in the direction of using wave/particle radiation devices to transmit sensing components, instruments, measuring instrument components, etc. The effect of large connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

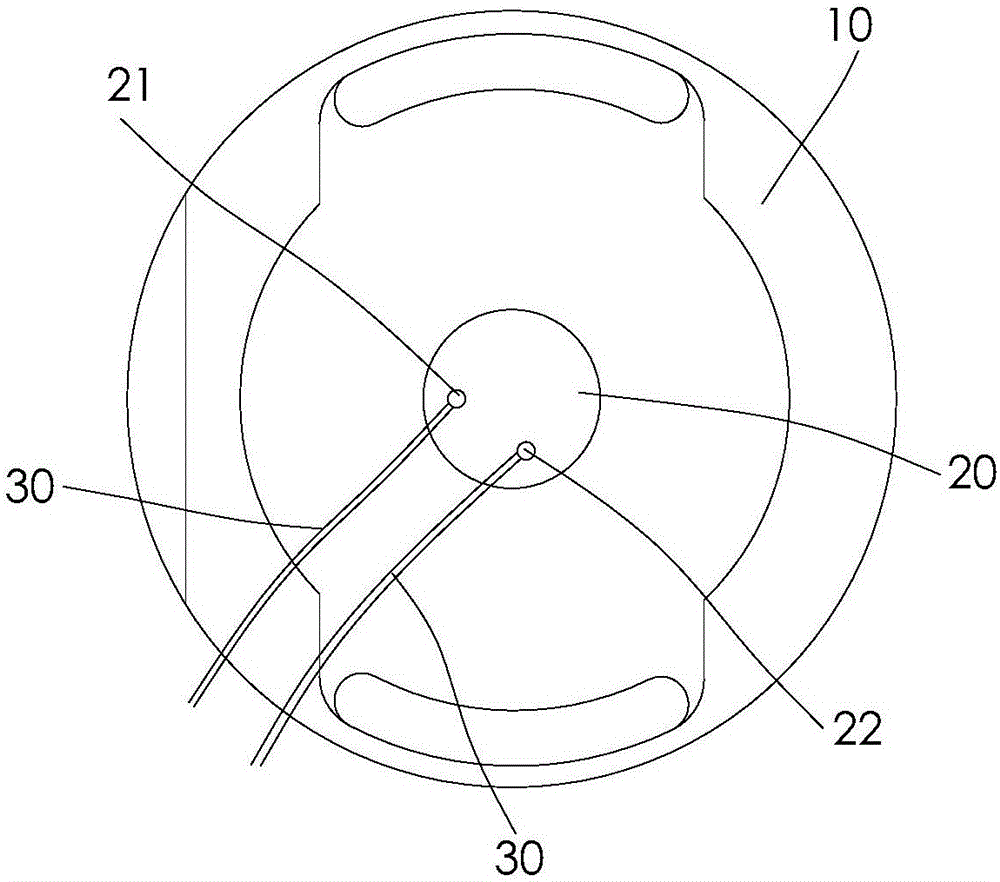

[0013] like figure 1 The shown electrode connection structure of an ultrasonic sensor includes an aluminum casing 10, a piezoelectric ceramic sheet 20 and two leads 30. Specifically, the piezoelectric ceramic sheet 20 is fixed in the aluminum casing 10, and the piezoelectric ceramic sheet is 20 is electrically connected to the aluminum shell 10, one side of the piezoelectric ceramic sheet 20 is provided with a positive electrode 21 and a negative electrode 22, one end of a lead 30 is electrically connected to the positive electrode 21 by welding, and the other lead 30 is electrically connected to the positive electrode 21. One end of the lead wire 30 is electrically connected to the negative electrode 22 by welding;

[0014] On the basis of the above structure, the piezoelectric ceramic sheet 20 is connected to the positive and negative electrodes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com