LCD EDID burning method

A technology of liquid crystal display and burning method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of long burning time, manpower and station occupation, high production cost, etc., and achieve small data volume, long transmission time, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

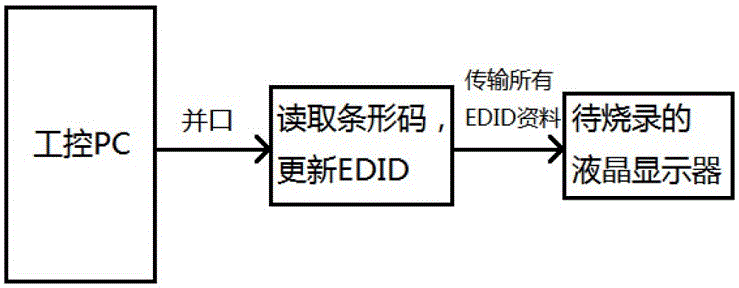

[0022] Please refer to figure 1 , in the prior art, the industrial control PC reads the barcode through the parallel port to update the EDID data, and transmits all the EDID data to the liquid crystal display to be burned for burning. In this process, the amount of data transmitted is too large and takes a long time.

[0023] The invention provides a liquid crystal display EDID burning method, comprising the following steps:

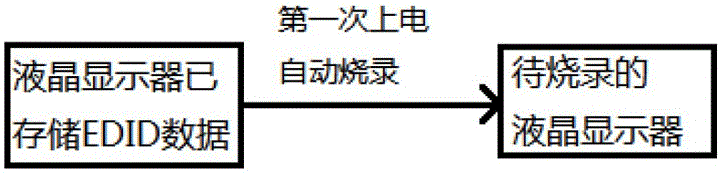

[0024] Step S1: Please refer to figure 2 , power on the liquid crystal display to be burned, and perform the first burning of EDID data, wherein, the liquid crystal display to be burned has pre-stored EDID data;

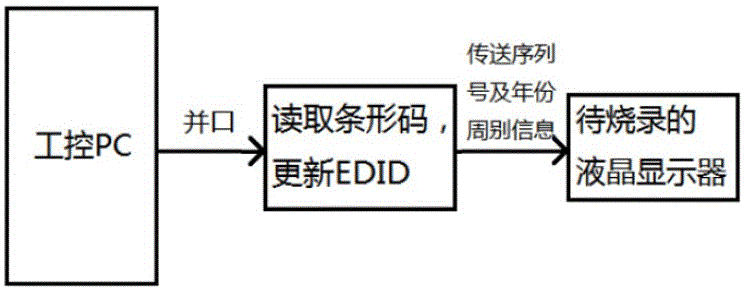

[0025] Step S2: Please refer to image 3 , connect the liquid crystal display to be burned to the host, the host will obtain the serial number by reading the barcode online and convert the manually entered date into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com