Intelligent logistics transport cart and logistics transport method

A technology of intelligent logistics and transportation vehicles, applied in the field of intelligent logistics transportation vehicles and logistics transportation, can solve the problems of untimely transportation, increased cost, and a large number of configurations, so as to avoid untimely, improve productivity, and reduce investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

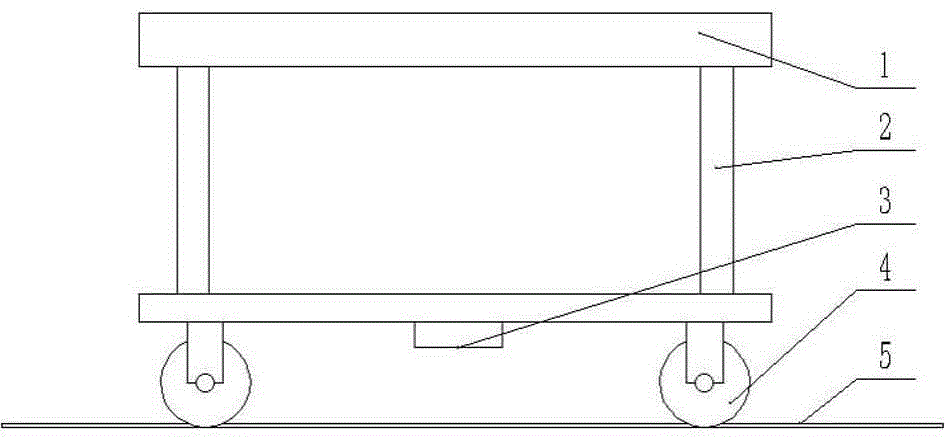

[0010] Such as figure 1 The shown intelligent transport vehicle includes a vehicle frame 2, a driving device and a control device capable of driving the rollers to rotate. , the control device includes an induction device and a control element, the induction device includes an induction element 3 and an emission element 5, the induction element 3 is arranged on the bottom of the vehicle frame 2, the emission element 5 is arranged on the required road surface, the induction element 3 and the driving device Both are connected with the control element, and two buttons "go" and "back" are arranged on the control element.

[0011] A logistics transport method, using the above-mentioned intelligent logistics transport vehicle, the steps are as follows:

[0012] a. Reasonably lay the launcher 5 on the ground between the assembly line and the logistics center;

[0013] b. When the transport vehicle is required to transport accessories, click the "go" button, the sensing element 3 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com