Active alignment apparatus for module assembling process

A focusing device and process technology, applied in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of poor assembly effect, difficult to meet the requirements of consistent product performance, and achieve the effect of good consistency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

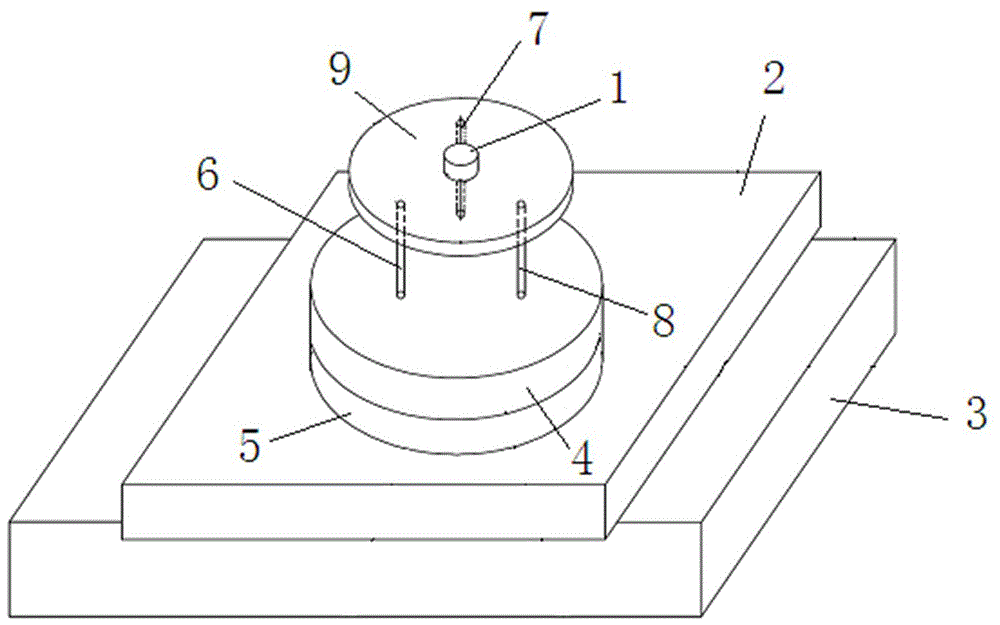

[0024] The specific implementation of the active focusing device for the module assembly process of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] See attached figure 1 , The active focusing device in the module assembly process realizes the six degrees of freedom adjustment of the lens during the chip-level product packaging process through the drive module. The device includes an X platform 2, a Y platform 3 and a Z platform 5, and the R platform 4 realizes the horizontal X-direction movement, the horizontal Y-direction movement, the Z-direction vertical movement and the R-direction rotational movement of the device respectively. It is also possible to use other motion platforms to realize the motion in the four directions of XYZR. The arrangement order of the X platform 2, Y platform 3, Z platform 5, and R platform 4 is not limited, as long as the movement of four degrees of freedom can be completed during work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com