High current anti-swing spring terminal

An anti-swing, high-current technology, applied in circuits, electrical components, parts of connecting devices, etc., can solve the problem of electrical wiring that cannot flow current, the contact area between male inserts and insert springs is small, and it is not suitable for higher power electrical wiring. requirements and other issues to achieve the effect of avoiding potential safety hazards, good electrical conductivity, safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

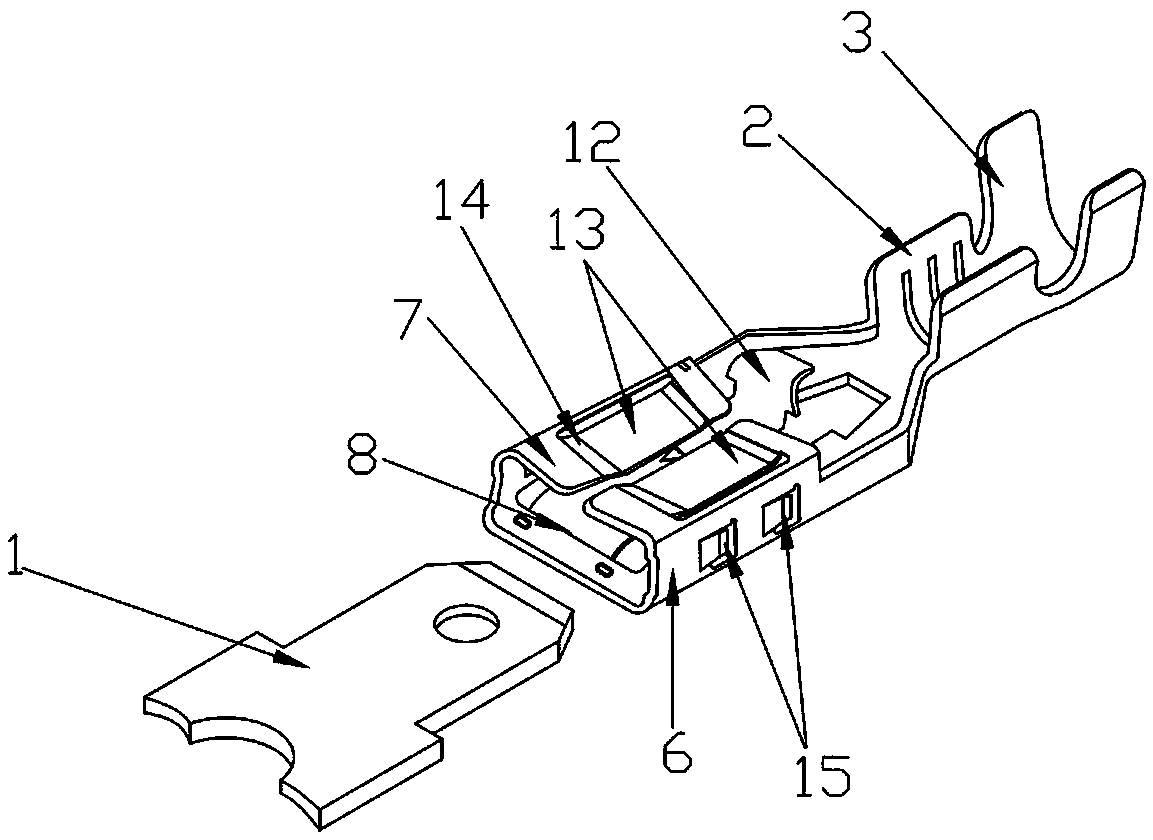

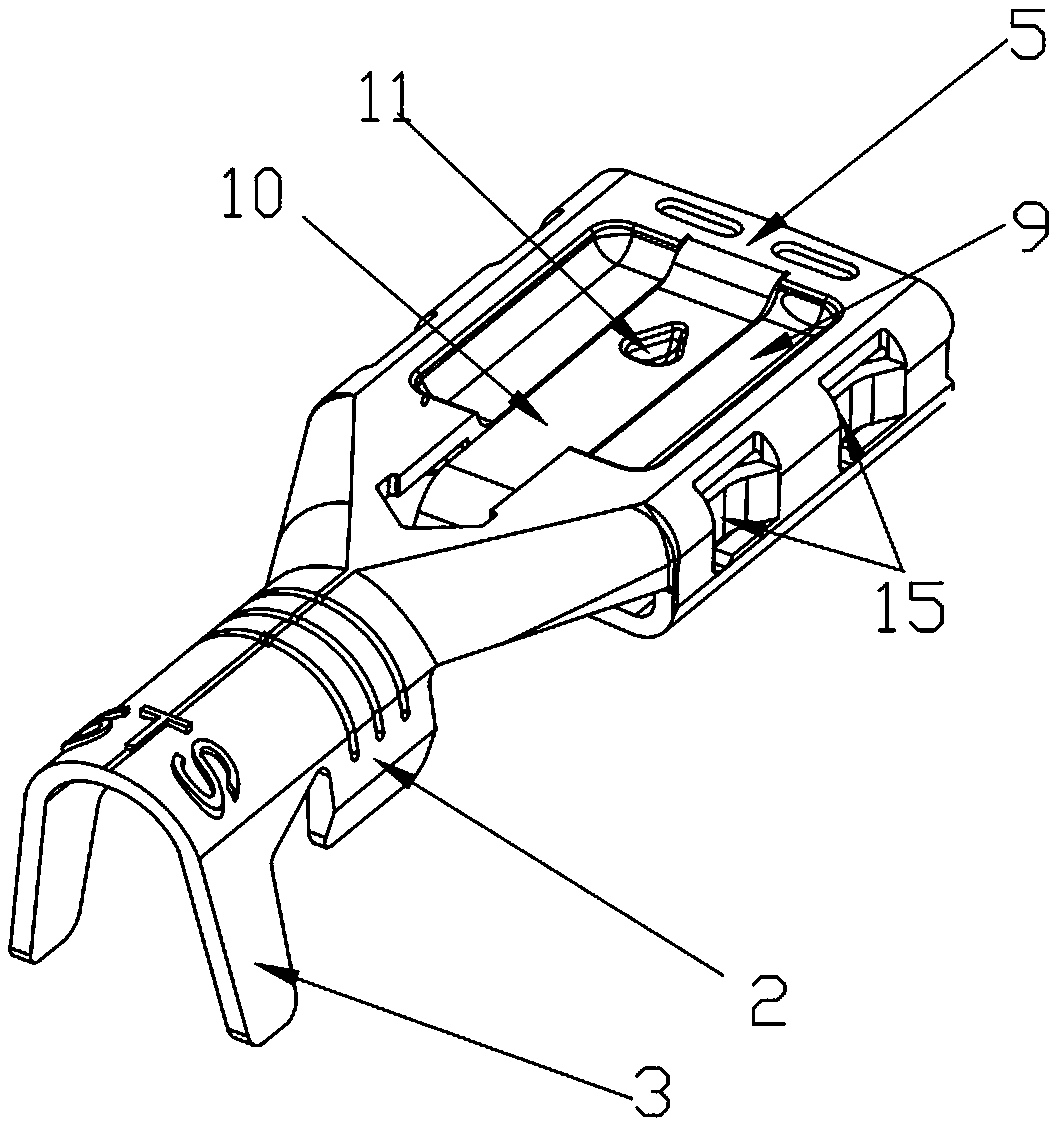

[0027] refer to Figure 1 to Figure 5 , the high-current anti-swing spring terminal specifically implemented includes a riveting foot and a spring. The riveting foot is located at the tail end of the spring terminal and is used to connect with a wire. The riveting foot is composed of a riveting core foot 2 and a riveting leather foot 3 Composition, the riveting thread leather foot 3 is arranged on the rear end of the riveting thread mandrel foot 2, and the inner surface of the riveting thread mandrel foot 2 and the riveting thread leather foot 3 are all provided with a wire placement groove 4 for matching and accommodating the wire, and the riveting thread mandrel foot 2 The inner side is provided with a raised horizontal crimping line for pressing the wire core. When connecting the wire, the wire is placed on the wire placement groove 4, and then the riveting wire core foot 2 and the riveting wire leather foot 3 are riveted to make the riveting wire core Pin 2 presses the wir...

Embodiment 2

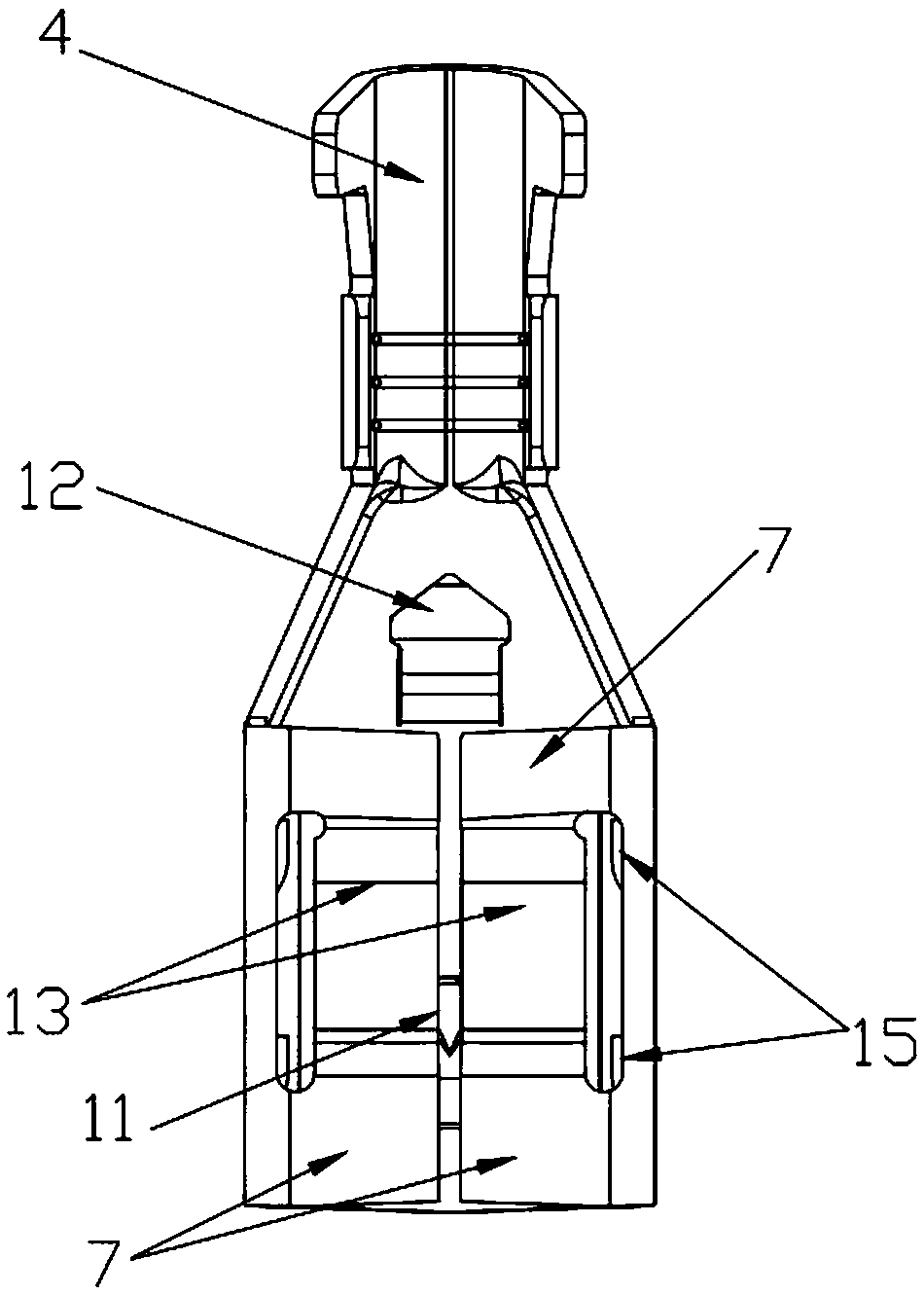

[0033] refer to Figure 6 The difference between the present embodiment and the first embodiment lies in the structure of the riveting core foot 2 and the riveting leather foot 3. Both the riveting core foot 2 and the riveting leather foot 3 extend upward and bend inward, forming a palm structure in combination. The center line of the wire placement groove 4 is perpendicular to the center line of the female end interface 8, thus forming a horizontal spring structure.

[0034] figure 1 and Figure 6 The male plug piece 1 is in the uninserted state. When the male plug piece 1 is inserted into the spring from the female end interface 8, the upper top platform 9 bears upward against the bottom surface of the male plug piece 1, and at the same time, the rear end of the upper spring piece 13 is affected by the male plug. The extrusion of the insert piece 1 withstands the rear stretching surface upwards, so that the top surface of the male insert piece 1 bears the pressure of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com