Device of accurately controlling rotation angle of clamping part and realization method thereof

A rotation angle and precise control technology, applied in the direction of feedback control, etc., can solve problems such as liquid bubbles in the bottle, light inspection interference, bottle vibration, etc., to achieve the effects of reducing loss, reducing interference, and suppressing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

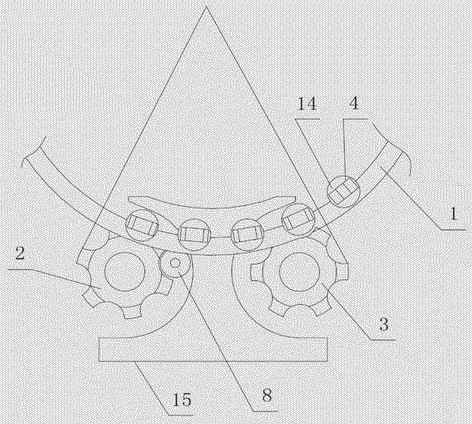

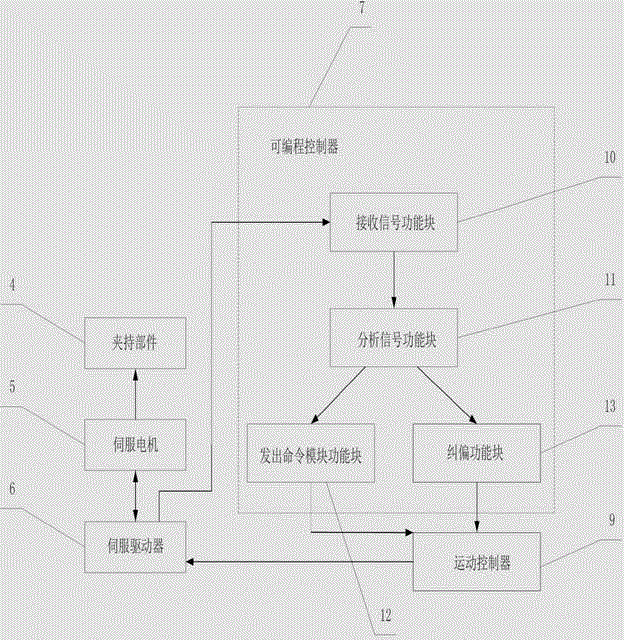

[0033] Such as figure 1 and figure 2 As shown, the device for precisely controlling the rotation angle of the clamping part includes a clamping part 4, a turntable 1, a bottle-in star wheel 2, a support frame 15, a bottle-out star wheel 3, a servo motor 5, a motion controller 9, a servo drive 6 and The programmable controller 7 is equipped with a plurality of installation holes 14 evenly on the turntable 1, and the installation holes 14 are evenly distributed on the outer edge of the turntable 1. Rotationally connected, the bottle-in star wheel 2 and the bottle-out star wheel 3 are respectively arranged on both sides of the support frame 15, and the bottle-in star wheel 2 and the bottle-out star wheel 3 are evenly provided with openings for clamping the bottle 8, and the opening and The size of the mounting holes is the same, and the opening corresponds to the mounting hole 14. The rotating shaft of the servo motor 5 is connected to the clamping part 4; The signal input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com