Pipe cable conveying device and method

A pipeline cable and conveying device technology, which is applied in the direction of cable installation, cable installation, transportation and packaging, etc., can solve the problems of difficult construction of cables through pipes, achieve simple and reasonable structure, improve work efficiency, and solve time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

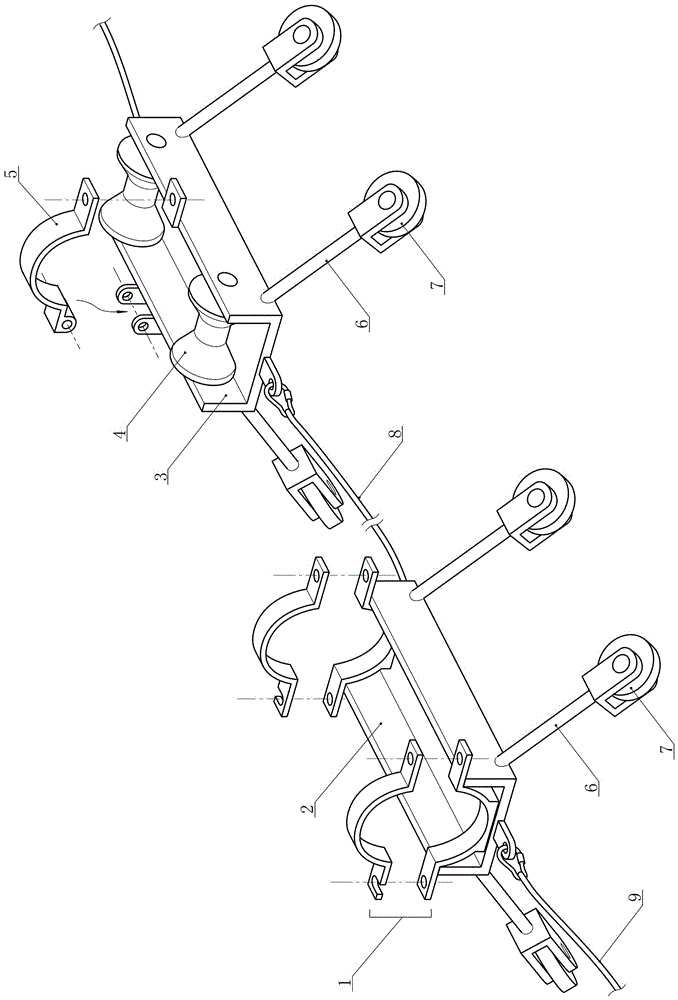

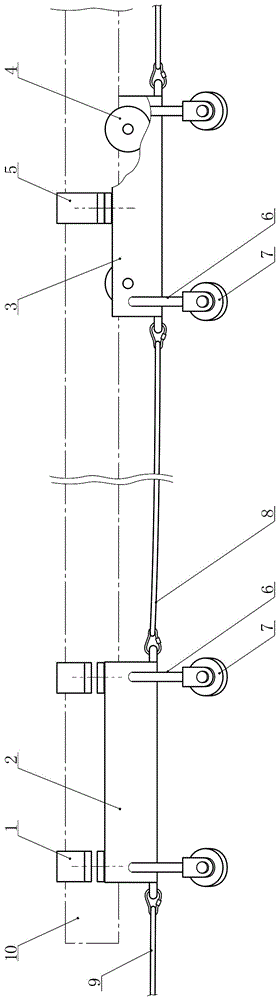

[0032] From figure 1 It can be seen that the present invention includes a tractor and a conveyor; the tractor includes a cable rack 2, a hoop 1, and a rolling bracket for walking; the upper part of the cable rack 2 is provided with a cable groove, and multiple hoops are provided in the groove for clamping Cable; the rolling support is composed of two poles 6 with rollers 7 at the lower ends, and the upper ends of the poles 6 are fixedly connected to both sides of the cable rack 2 (or arranged at the bottom according to the situation). In this embodiment, the cable rack 2 is fixed with two groups of rolling brackets, and a hoop 1 is arranged at both ends of the cable groove.

[0033] The conveyor includes a support bracket 3, a shaft roller 4 for supporting the cable, an anti-off clamp 5 to prevent the cable from falling off, and a rolling bracket for walking; the upper part of the support bracket 3 is equipped with a plurality of horizontally arranged shaft rollers at interval...

Embodiment 2

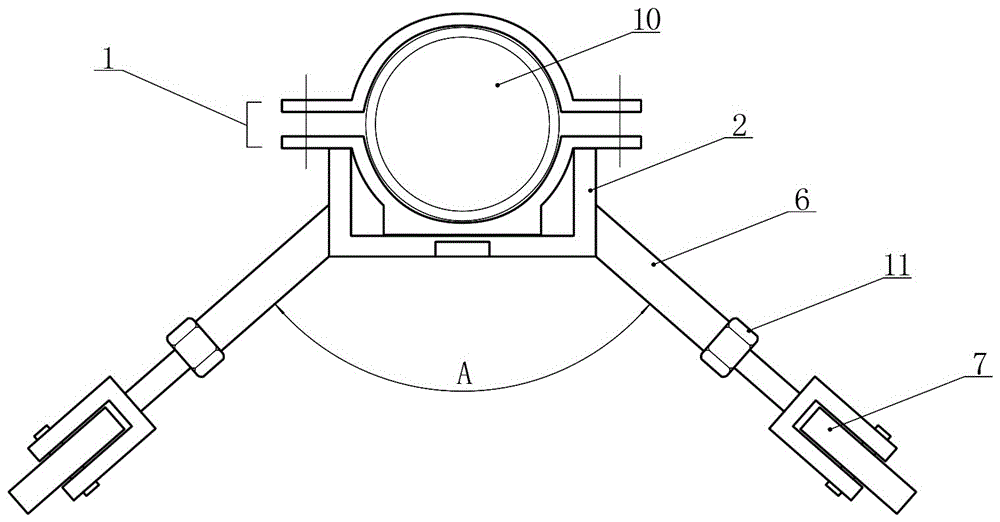

[0050] From image 3 It can be seen that the difference between this embodiment and Embodiment 1 is that the angle A between the two poles of the rolling support is 100 degrees; Positioning, pole length can be adjusted according to the construction site conditions.

[0051] Other technical features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com