Thermoforming apparatus

A thermoforming and hot plate technology, applied in the direction of coating, etc., can solve the problems of loss of air outflow space, flake blockage due to softening of vacuum holes, uneven heating of flakes, etc., and achieve the effect of suppressing quality degradation and reducing imprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

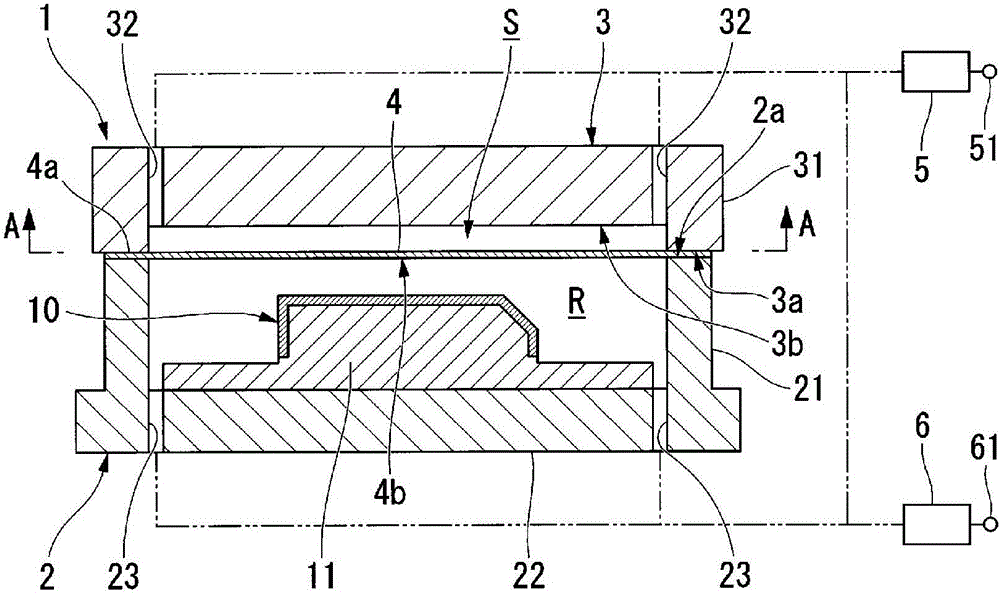

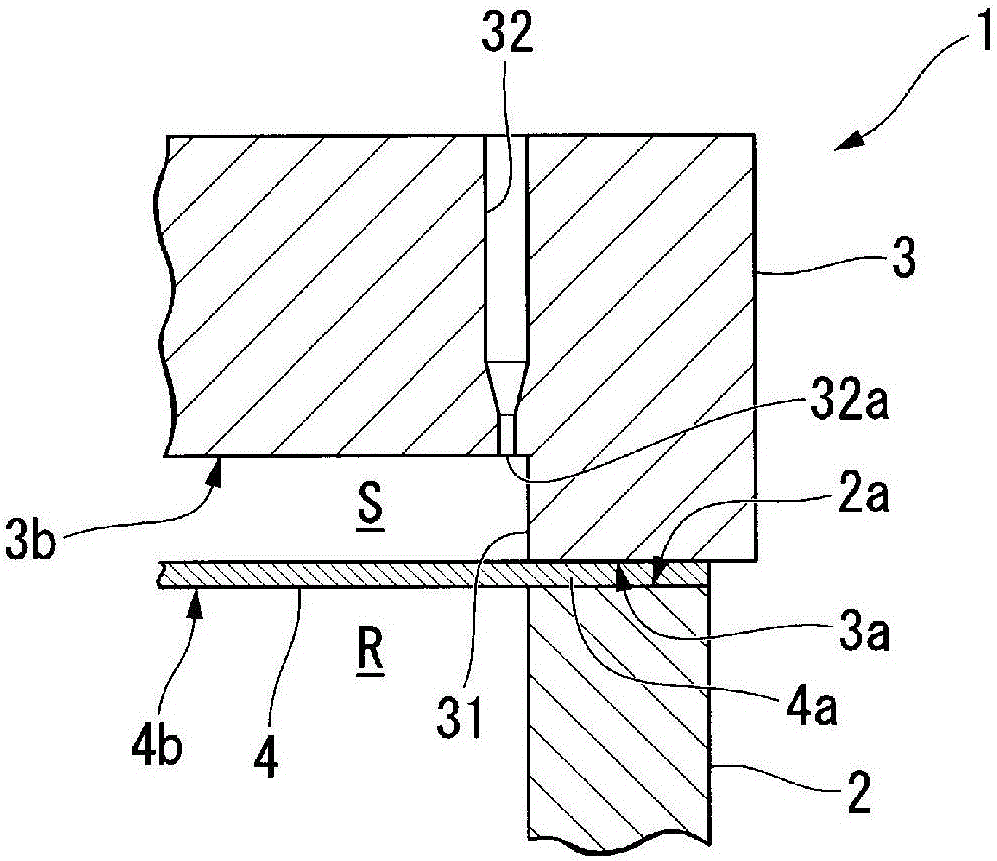

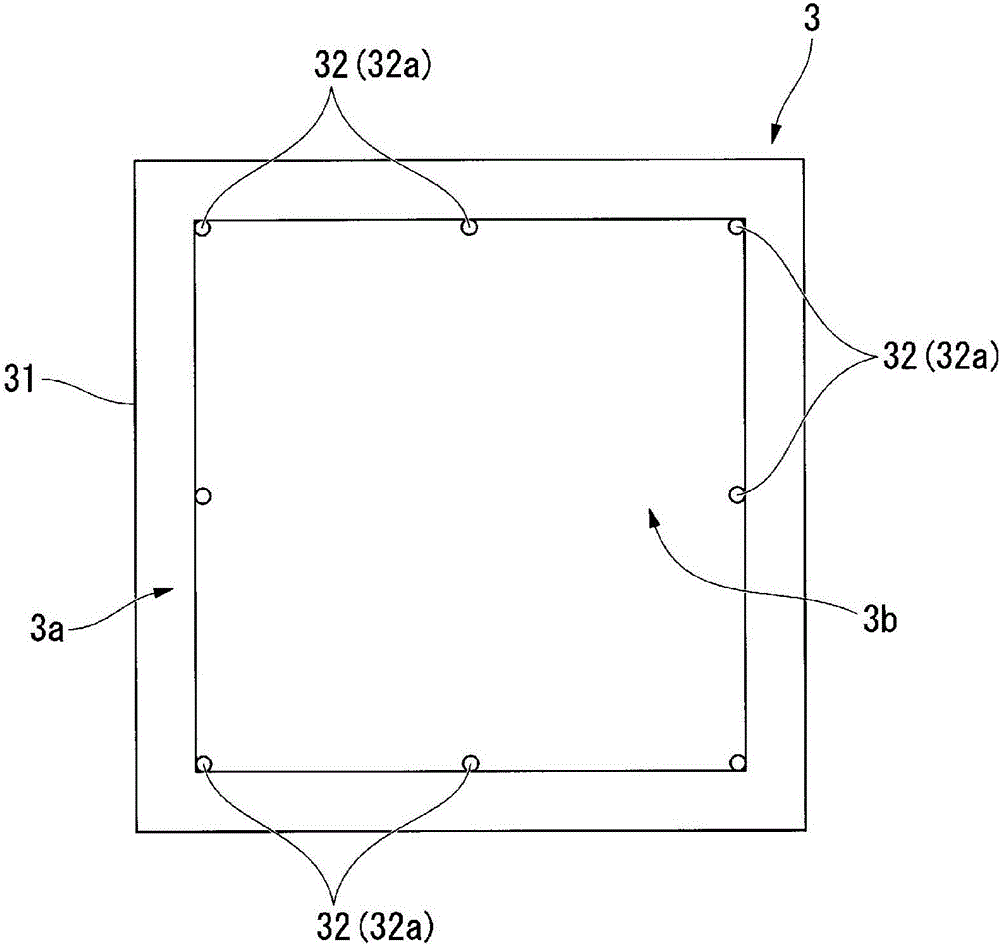

[0058] Hereinafter, the thermoforming device provided by the embodiment of the present invention will be described with reference to the accompanying drawings.

[0059] Such as figure 1 As shown, the thermoforming device 1 provided by the embodiment of the present invention is used for overmolding the adhesive sheet 4 on the substrate 10 .

[0060] The thermoforming device 1 has a lower frame 2 having a space (accommodating area R) capable of accommodating a substrate 10 and a hot plate 3 having a frame upper edge portion 2a capable of abutting against the lower frame 2 . The abutment surface 3a. The structure is such that a resin sheet 4 is provided between the lower frame 2 and the hot plate 3 , and the sheet 4 is heated to adhere to the base material 10 for thermoforming. Here, the substrate 10 is formed into a thermoformed product by bonding the sheets 4 , and is clamped by the substrate holder 11 in the thermoforming apparatus 1 .

[0061] However, the thermoforming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com