Transfer roll for imprinting

A technology for transfer rollers and roller bodies, which is applied in the field of transfer roller bodies for embossing, and can solve the problems of time-consuming and labor-intensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

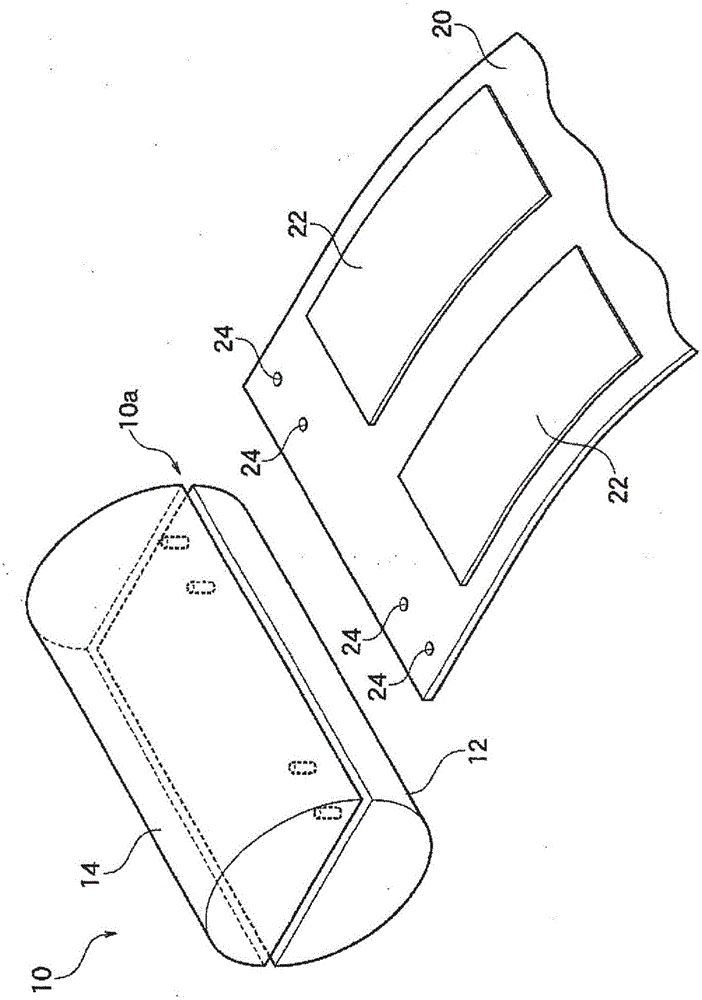

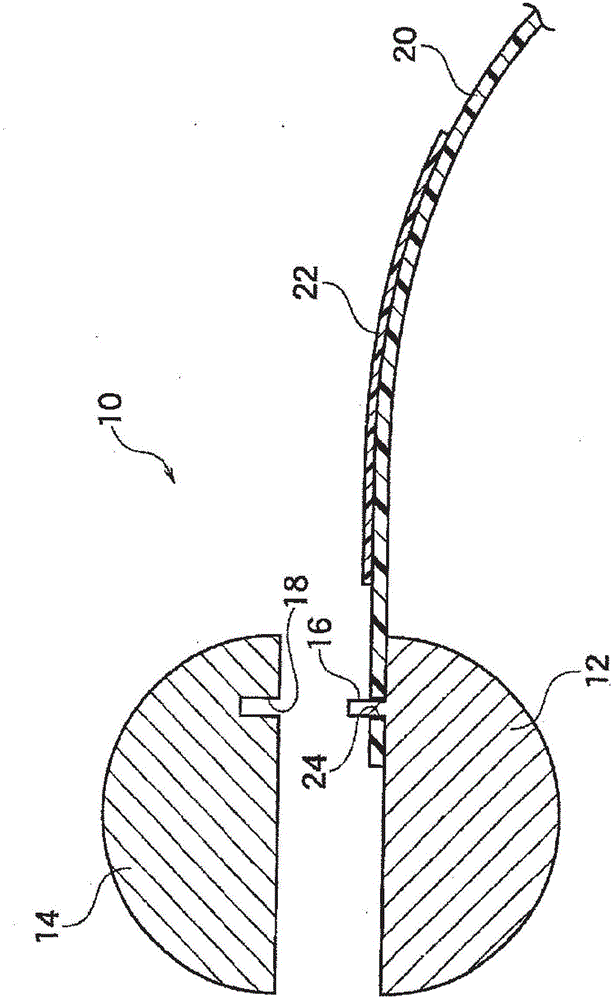

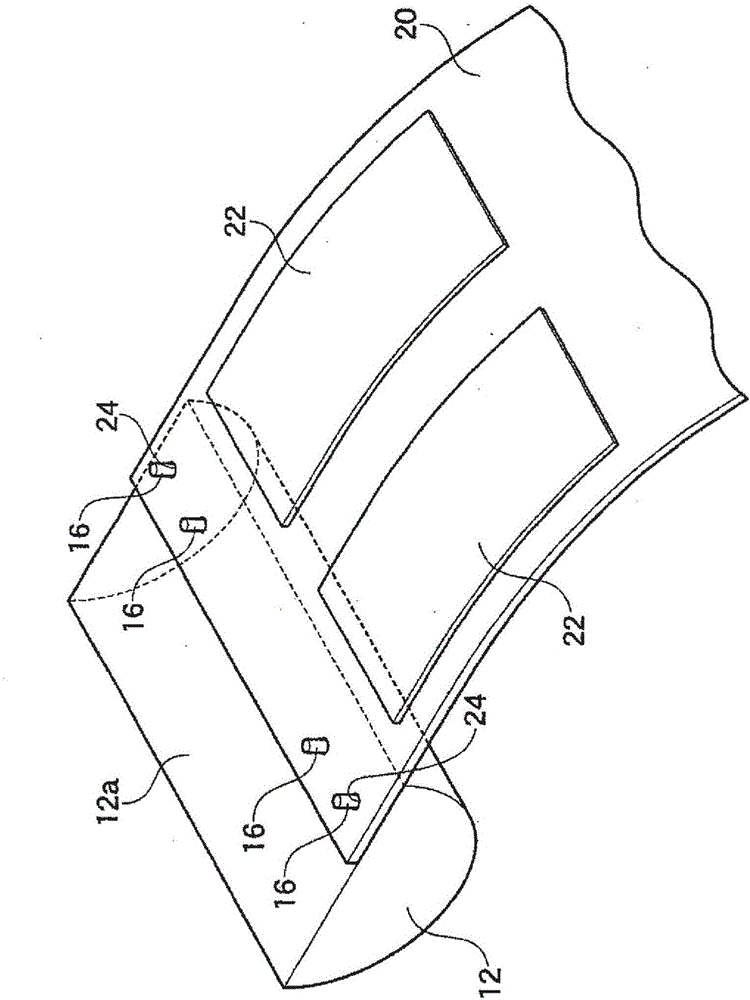

[0031] Next, a transfer roller body for imprinting formed according to a preferred embodiment of the present invention will be described with reference to the drawings.

[0032] The transfer roller body for imprinting of the present invention is a transfer roller body for imprinting in which a resin film substrate with a resin template having a fine concave-convex pattern formed on its surface is wound around the peripheral surface of the roller body. is that

[0033] By dividing the roll body into two, the roll body is composed of one split body and the other split body, and one side end of the resin film substrate is sandwiched by the first split body. Between the two split surfaces joined to the second split body, after the first split body and the second split body are integrated, the resin film base material is wound along the circumferential direction of the roll body. around.

[0034] Figure 1 ~ Figure 4 A transfer roller body 10 for imprint according to a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com