Laminated Body With Sealant Film

A laminated body and sealing film technology, applied in coatings, layered products, household appliances, etc., can solve problems such as high humidity dependence, reduced oxygen or water vapor barrier properties, and inability to cope with hot water sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

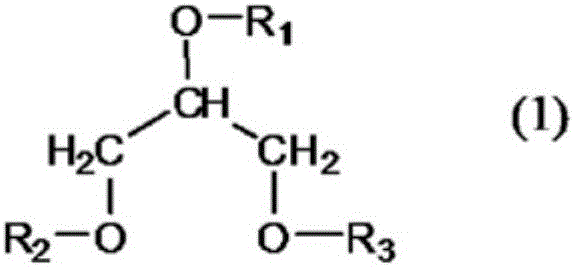

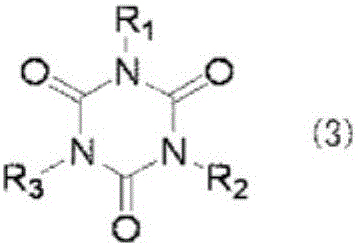

[0229] (Production example 1) Resin (b1): Production example of THEI (OPAEG) 3

[0230] Add 1136.5 parts of phthalic anhydride, 495.3 parts of ethylene glycol, and tris(2-hydroxyethyl)isocyanuric acid to a polyester reaction vessel equipped with a stirrer, nitrogen introduction tube, rectification tube, moisture separator, etc. 668.1 parts of ester and tetraisopropyl titanate in an amount equivalent to 100 ppm relative to the total amount of polycarboxylic acid and polyhydric alcohol. Slowly heat it so that the upper part of the rectification tube does not exceed 100°C and keep the internal temperature at 220°C. When the acid value reaches 1 mgKOH / g or less, the esterification reaction is terminated, and a polyester polyol with a number average molecular weight of 860, a hydroxyl value of 195.4 mgKOH / g, and an acid value of 0.9 mgKOH / g is obtained. The number of design functional groups per molecule of the resin (A) was 3 hydroxyl groups and 0 carboxyl groups, and the solubility...

manufacture example 2

[0231] (Production example 2) Resin (b1): Production example of GLY(OPAEG)+MA

[0232] Add 1316.8 parts of phthalic anhydride, 573.9 parts of ethylene glycol, and 409.3 parts of glycerol to a polyester reaction vessel equipped with a stirrer, nitrogen introduction tube, rectification tube, moisture separator, etc. The total amount of is equivalent to 100 ppm of tetraisopropyl titanate, which is slowly heated so that the temperature of the upper part of the rectifying tube does not exceed 100°C, and the internal temperature is maintained at 220°C. When the acid value reaches 1 mgKOH / g or less, the esterification reaction is terminated, and a polyester polyol with a hydroxyl value of 339.9 mgKOH / g is obtained. Then, the temperature was lowered to 120°C, 421.8 parts of maleic anhydride was added thereto, and the temperature was maintained at 120°C. When the acid value reaches approximately half of the acid value calculated from the added amount of maleic anhydride, the esterificati...

manufacture example 3

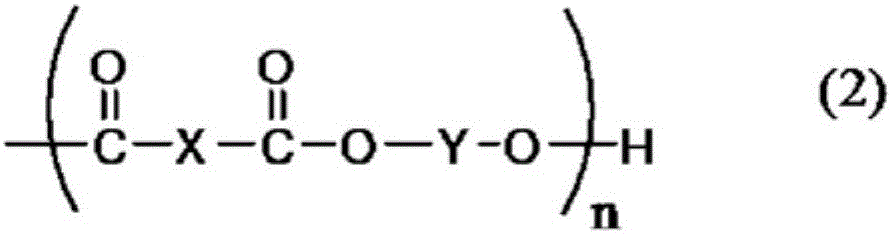

[0233] (Manufacturing Example 3) Resin (b1): Manufacturing method of EGOPA (0.9K)

[0234] Add 148.1 parts of phthalic anhydride, 84.2 parts of ethylene glycol, and 0.03 parts of tetraisopropyl titanate to a polyester reaction vessel equipped with a stirrer, nitrogen introduction tube, rectification tube, moisture separator, etc. The upper part of the distillation tube is slowly heated so that the temperature does not exceed 100°C, and the internal temperature is maintained at 205°C. When the acid value reaches 1 mgKOH / g or less, the esterification reaction is terminated, and a polyester polyol with a number average molecular weight of 900, a hydroxyl value of 126.2 mgKOH / g, and an acid value of 0.36 mgKOH / g is obtained. The number of designed functional groups per molecule of the resin (A) was 2 hydroxyl groups and 0 carboxyl groups, and the solubility of the resin (A) was judged as ○.

[0235] (Preparation of Adhesive A)

[0236] Mix the resin, inorganic compound, and solvent des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com