Heat sealing PVDC emulsion having antifogging function and preparation method thereof

A heat-sealed, emulsion technology, applied in the field of new polymer materials, can solve the problems of no anti-fog performance, customers can't see clearly, products reduce the desire to buy, etc., and achieve the effect of stable emulsion performance, easy control, and good oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

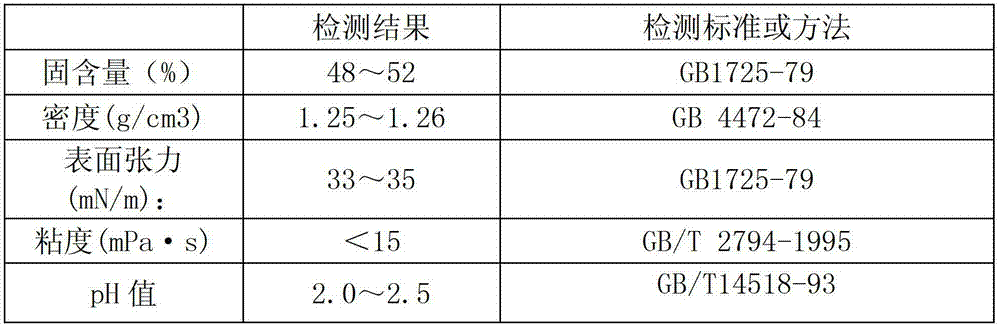

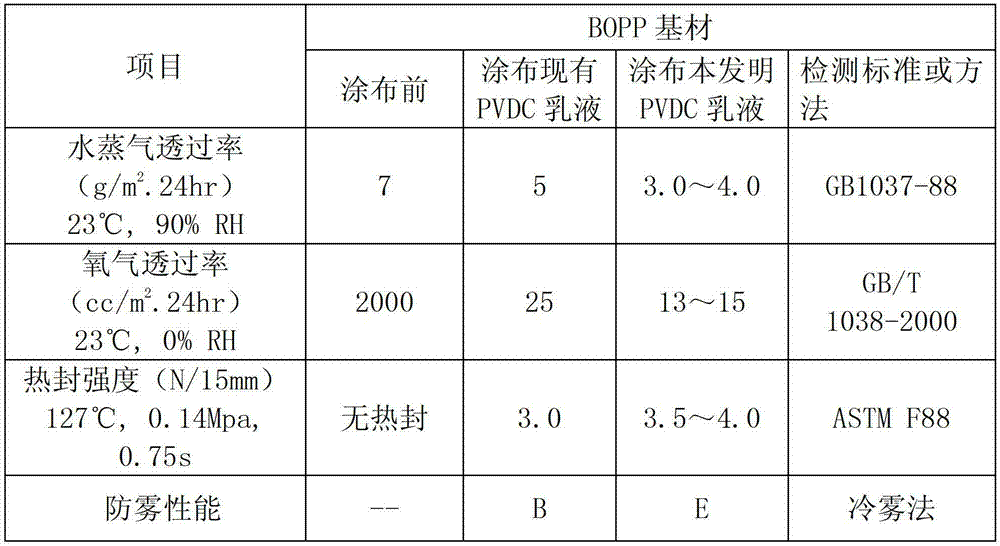

[0029] A heat-sealable PVDC emulsion with anti-fogging function. The raw materials are prepared according to the following components (unit: kg)

[0030]

[0031] The above-mentioned preparation method of heat-sealable PVDC emulsion with anti-fogging function: 1. First, 30.0 kg of vinylidene chloride, 0.7 kg of butyl acrylate, and 0.65 kg of methacrylic acid are thoroughly mixed and stirred for 1 hour to obtain mixed monomer A; 0.5kg of sodium lauryl sulfate was mixed and stirred with 7.0kg of deionized water for 1h, and the stirring speed was 80 rpm to obtain emulsifier B; dissolve 0.02kg of tert-butyl hydrogen peroxide with 5.2kg of deionized water. Initiator C; Dissolve 0.02 kg of sodium formaldehyde sulfoxylate with 5.2 kg of deionized water to form initiator D. Add the remaining deionized water, 1.95kg of mixed monomer A, 0.2kg of emulsifier B, 0.1kg of initiator C, and 0.8kg of glacial acetic acid in the polymerization kettle, turn on the stirring, and the stirring speed is...

Embodiment 2

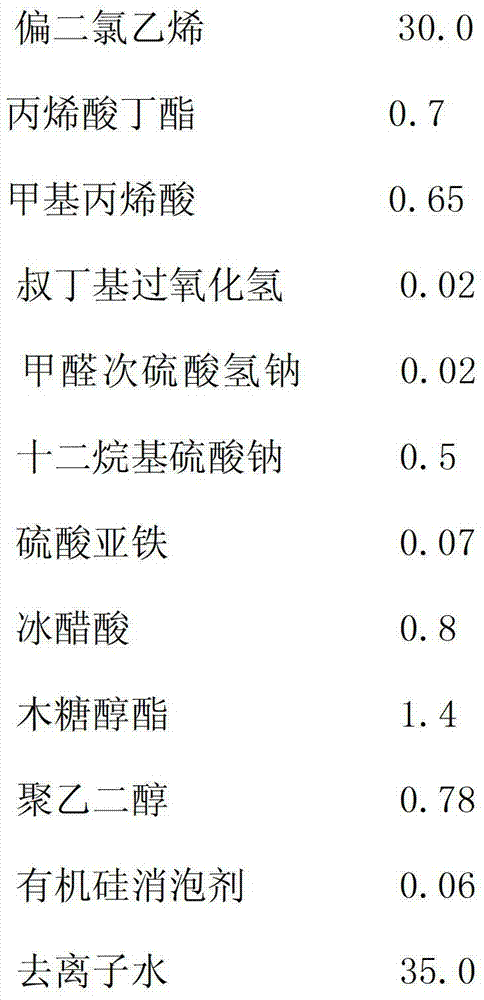

[0034] A heat-sealable PVDC emulsion with anti-fogging function. The raw materials are prepared according to the following components (unit: kg)

[0035]

[0036]

[0037] The above-mentioned preparation method of heat-sealing PVDC emulsion with anti-fogging function: 1. First, 48.0kg vinylidene chloride, 5.6kg butyl acrylate, 4.0kg acrylic acid are thoroughly mixed and stirred for 1.2h to obtain mixed monomer A; Mix 0.28kg of sodium lauryl sulfate with 15.0kg of deionized water and stir for 1h at a stirring speed of 80 rpm to obtain emulsifier B; dissolve 0.07kg of tert-butyl hydroperoxide with 11.0kg of deionized water Prepare initiator C; Dissolve 0.07 kg of sodium formaldehyde sulfoxylate with 11.0 kg of deionized water to prepare initiator D. Add the remaining deionized water, 5.0kg of mixed monomer A, 0.3kg of emulsifier B, 0.25kg of initiator C, and 2.7kg of glacial acetic acid in the polymerization kettle. The stirring speed is 70 rpm. , Protected by nitrogen, heated to ...

Embodiment 3

[0040] A heat-sealable PVDC emulsion with anti-fogging function. The raw materials are prepared according to the following components (unit: kg)

[0041]

[0042] The preparation method of the above heat-sealable PVDC emulsion with anti-fogging function: 1. Firstly, 70.0 kg of vinylidene chloride, 9.5 kg of butyl acrylate, 0.4 kg of acrylic acid, and 1.5 kg of methacrylic acid are thoroughly mixed and stirred for 1 hour to obtain Mix monomer A; mix 7.5 kg of sodium lauryl sulfate with 20.0 kg of deionized water and stir for 1 h at a stirring speed of 80 revolutions / min to obtain emulsifier B; combine 0.03 kg of tert-butyl hydrogen peroxide with 15.0 Dissolve kg of deionized water to form initiator C; dissolve 0.03 kg of sodium formaldehyde sulfoxylate with 15.0 kg of deionized water to form initiator D. Add the remaining deionized water, 6.2kg of mixed monomers, 0.58kg of emulsifier B, 0.35kg of initiator C, and 1.4kg of glacial acetic acid to the polymerizer. Turn on the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com