Rope for elevator and manufacturing method therefor

一种升降机、绳索的技术,应用在升降机、纺织品和造纸、纺织电缆等方向,能够解决线材强度增加、高破断载荷、高安全系数等问题,达到提高乘用舒适性、优异圆度和尺寸稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention relates to an elevator rope for a super high-rise building and a manufacturing method thereof.

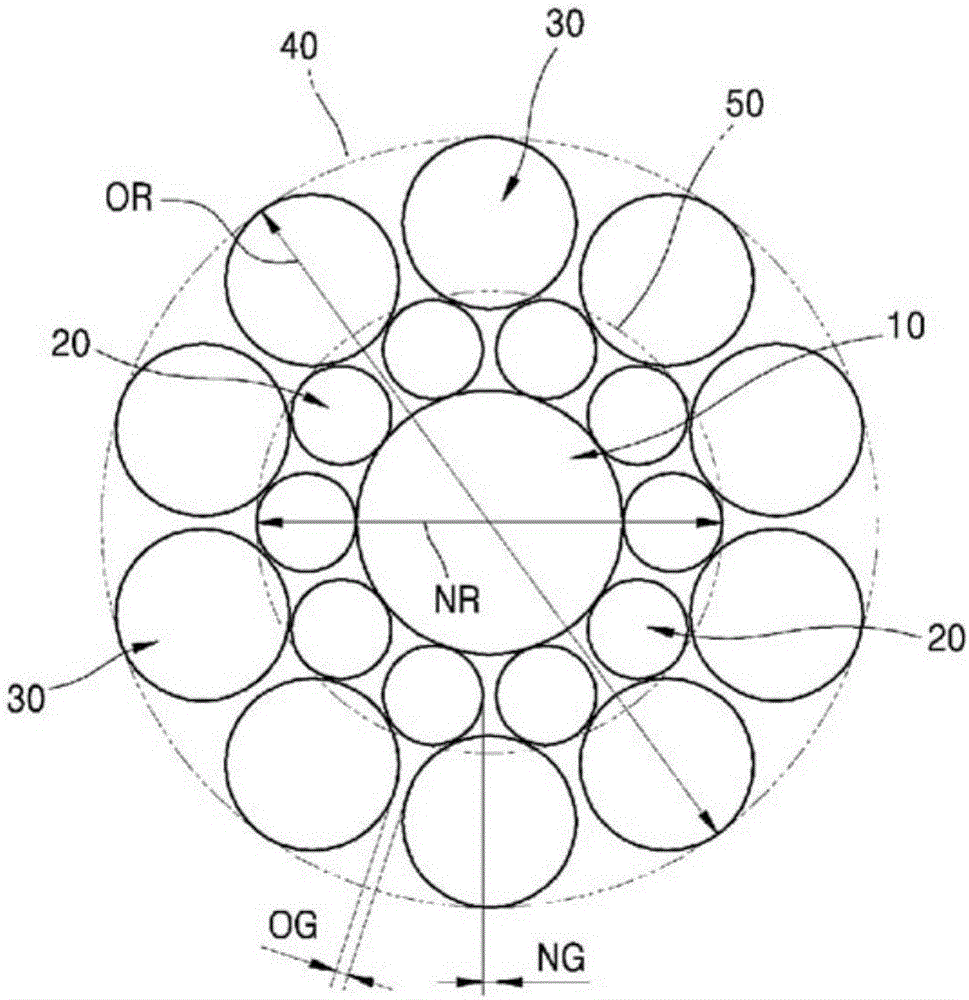

[0020] In the following, reference will be made to the attached figure 1 and figure 2 Exemplary embodiments according to the present invention will be described in detail.

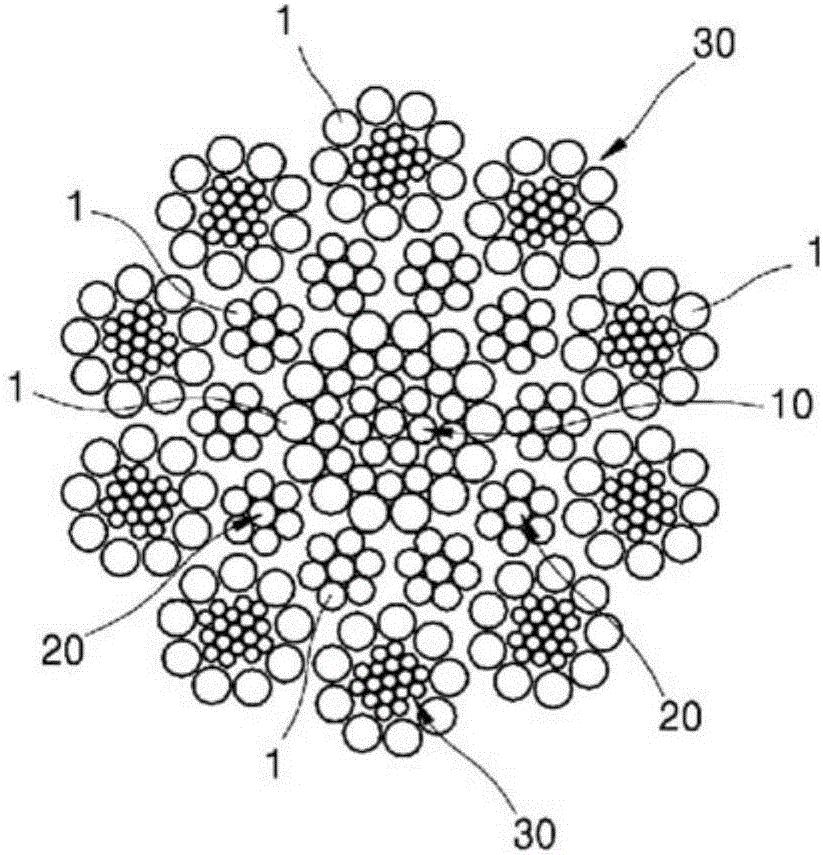

[0021] like figure 1 As shown, a rope for an elevator according to an aspect of the present invention includes a central strand 10 , an inner strand 20 and an outer strand 30 .

[0022] The central strand 10 is arranged at the center of the rope for the elevator and is formed by twisting a plurality of wires 1 . The plurality of wires 1 are made of steel.

[0023] The inner layer strands 20 are provided along the outer circumference of the center strand 10, and according to the present embodiment, ten inner layer strands 20 are prepared. Each of the inner layer strands 20 is formed by twisting a plurality of wires 1 .

[0024] The outer layer strands 30 are provided along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com