High strength antimicrobial glass

An anti-microbial, glass technology, used in the manufacture of anti-microbial glass, chemically strengthened glass, and anti-destructive fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

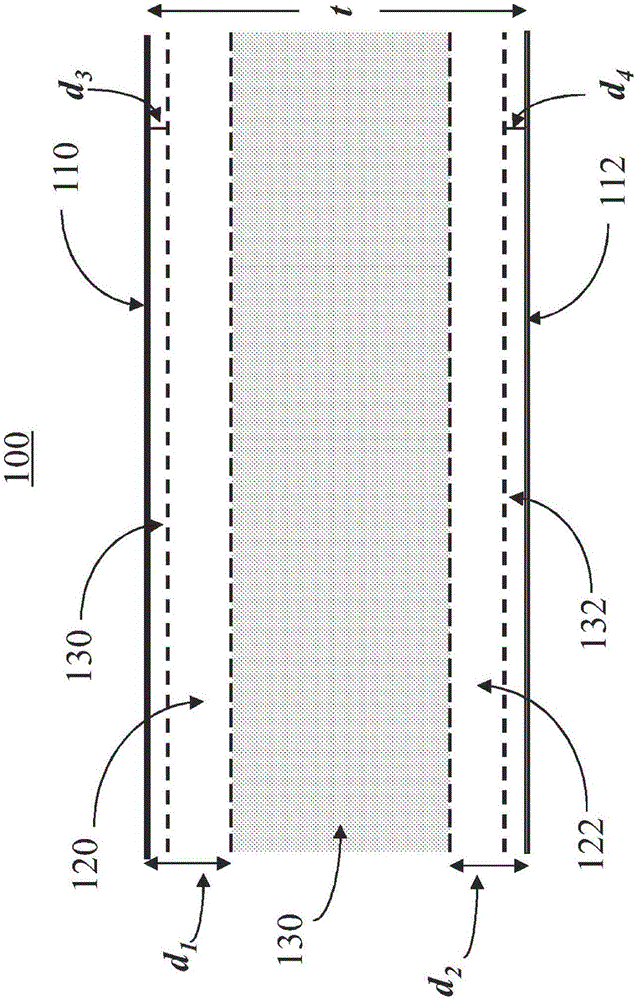

[0012] In the following description, the same reference numerals denote similar or corresponding parts in the several views shown in the drawings. It should also be understood that terms such as "top", "bottom", "outwardly", "inwardly", etc. are words of convenience and do not constitute limitations of the terms unless otherwise indicated. Furthermore, whenever a group is described as comprising at least one of a set of elements and combinations thereof, it will be understood that the set may contain any number of those listed elements, either singly or in combination with each other, or Consists mainly of them, or consists of them. Similarly, whenever a group is described as consisting of at least one of a group of elements or a combination of them, it is to be understood that the group may consist of any number of those listed elements, either singly or in combination. composition. Unless otherwise indicated, the recited numerical ranges include both the upper and lower li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com