Continuously variable planetary transmission

A planetary transmission, variable technology, applied in the field of drive train, can solve problems such as changing the transmission ratio, achieve the effect of high energy efficiency and increase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

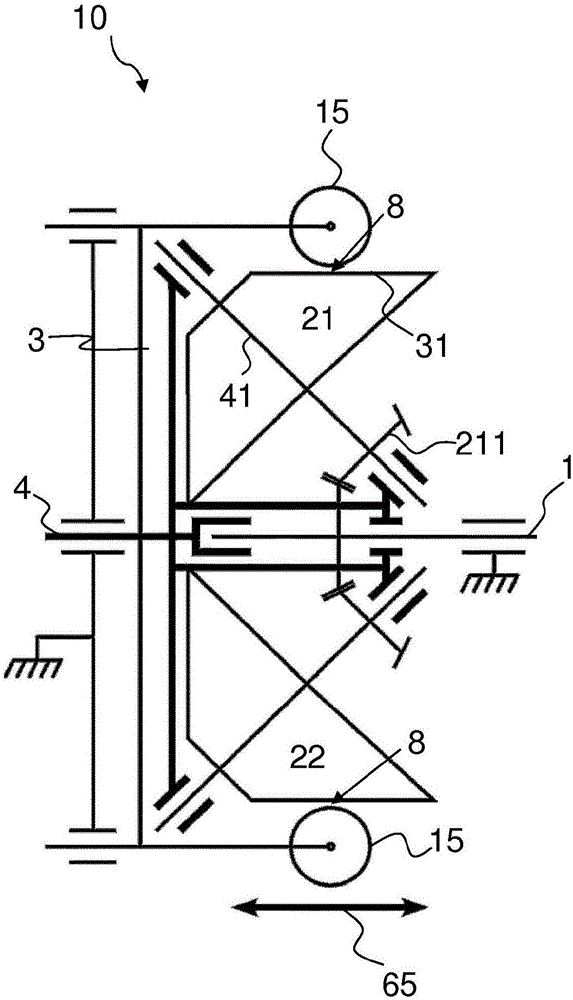

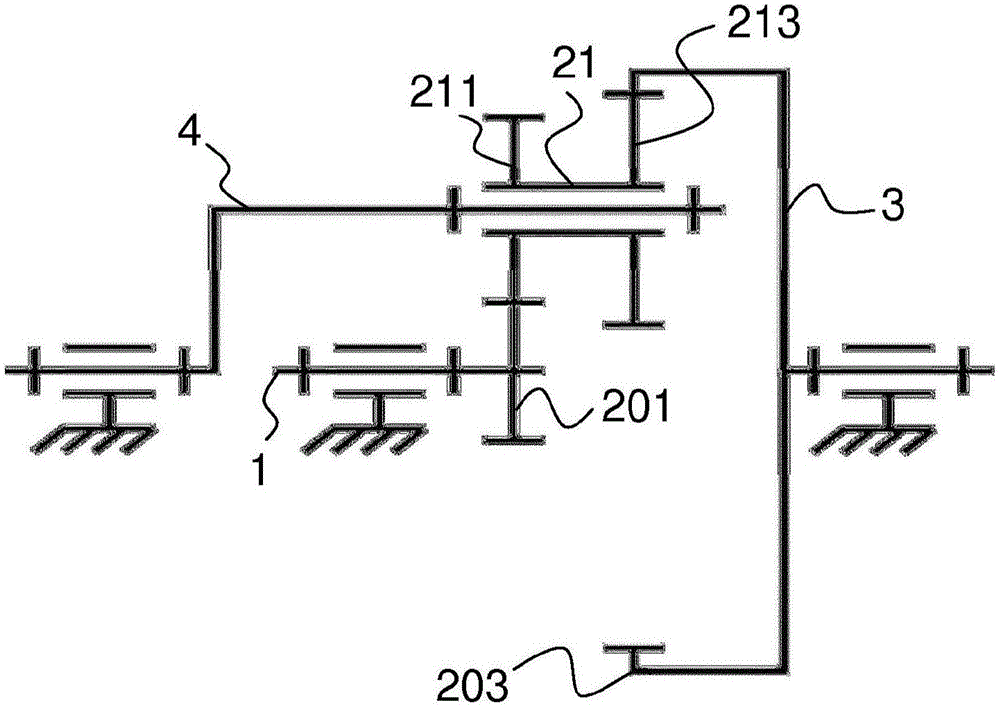

[0053] figure 1 A continuously variable planetary transmission 10 (or transmission 10 ) of the present invention is schematically shown according to a preferred embodiment. It comprises sun gear 1 or sun gear member or sun gear component or sun gear mechanism. Preferably, the sun gear 1 includes a sun shaft and a sun gear. Thus, in some preferred embodiments, the sun shaft may be either the output shaft or the input shaft of the transmission 10 . The transmission 10 also includes a planet carrier 4 or a planet carrier component or a planet carrier part or a planet carrier mechanism. Preferably, this planet carrier 4 is connected to a transmission shaft or an electric motor. In this case, the planet carrier 4 is therefore the input to the transmission 10 . However, in another preferred embodiment the planet carrier 4 may be connected to the output.

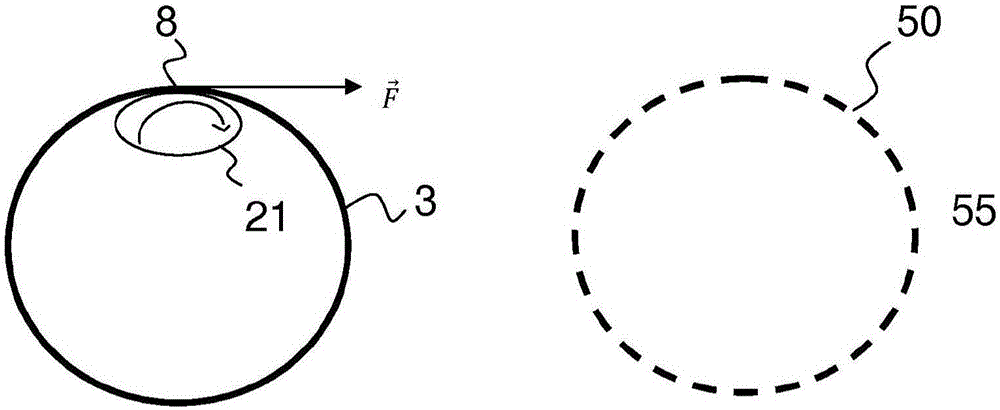

[0054] The transmission 10 also includes a first planetary gear 21 . This first planet wheel 21 has a first rotational axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com