Pump bearing structure

A technology for bearings and pumps, applied to bearing components, shafts, bearings, pumps, etc., can solve the problems of increased maintenance costs, increased wear and water leakage opportunities, and reduced tightness of the adapter 74, so as to improve wear and water leakage, The effect of streamlining widget settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

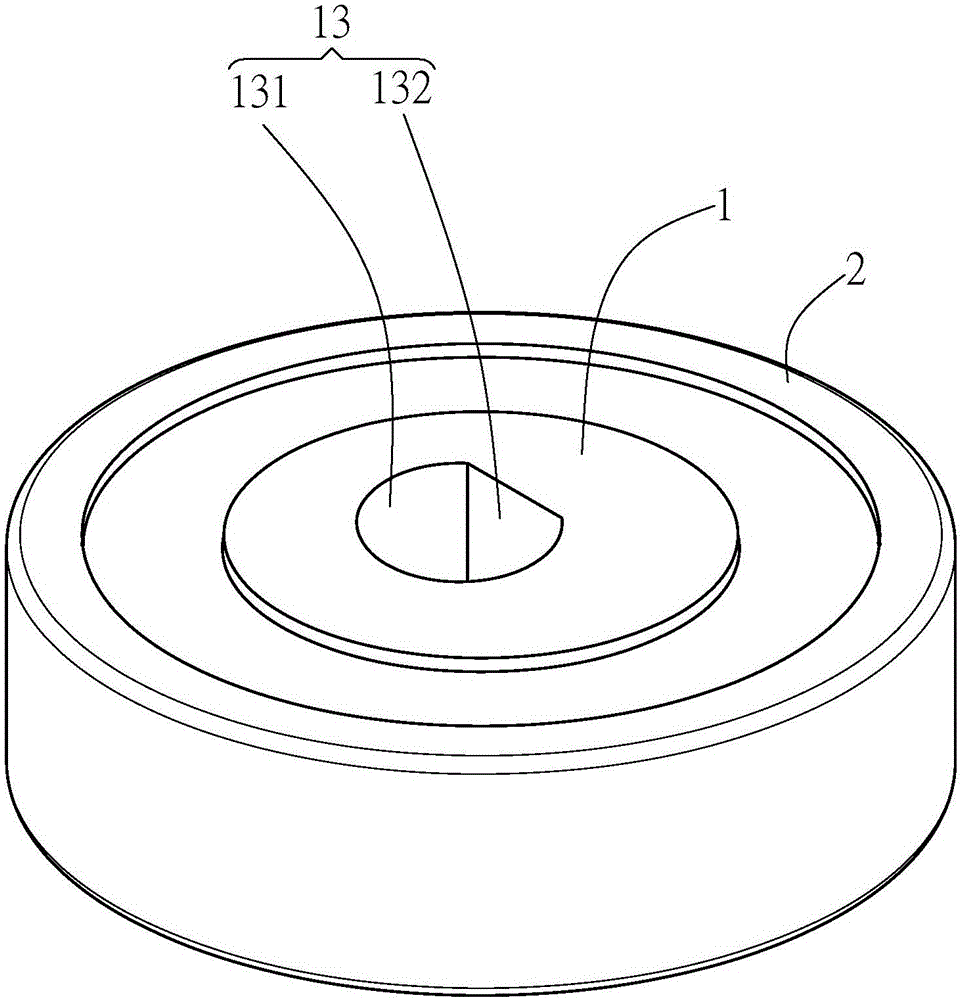

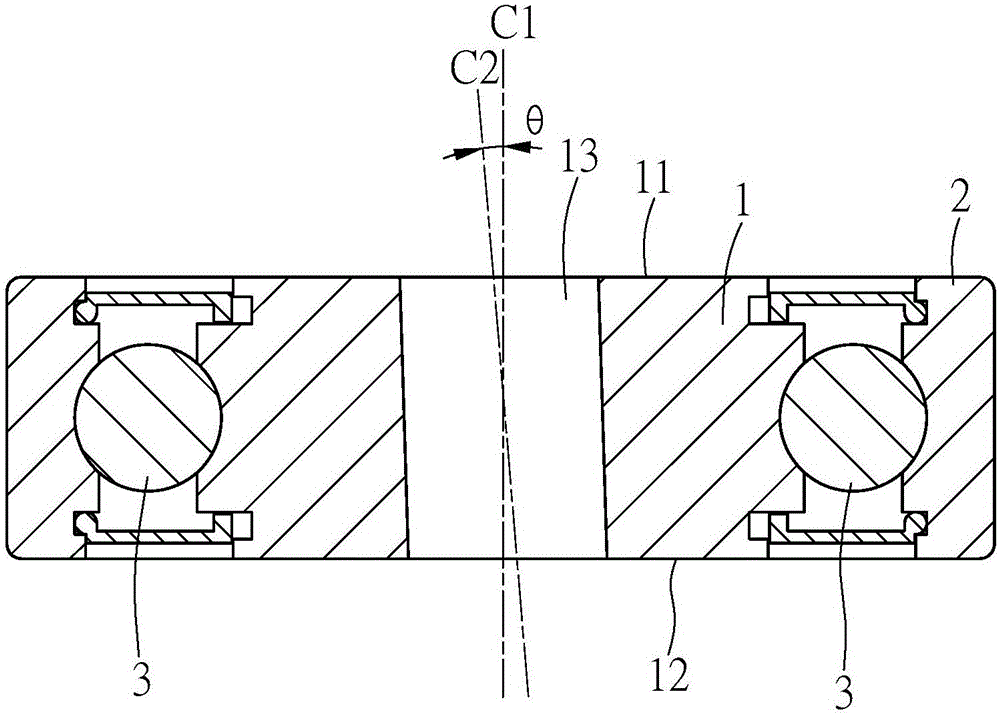

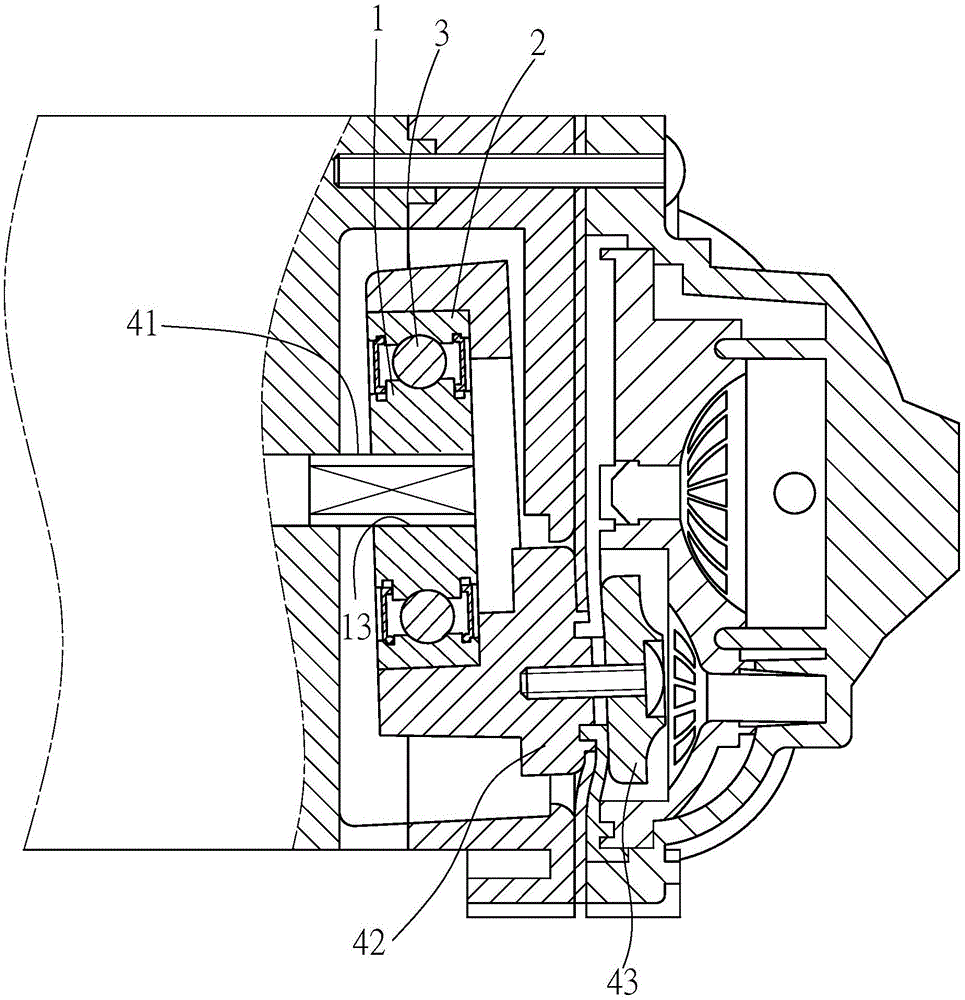

[0023] see figure 1 , 2 , shows the first embodiment of the pump bearing structure provided by the present invention, which includes an inner shaft sleeve 1 and an outer shaft sleeve 2, wherein the outer shaft sleeve 2 is arranged on the outer periphery of the inner shaft sleeve 1, and can be relatively The inner shaft sleeve 1 rotates. Several rolling elements 3 are arranged between the outer bushing 2 and the inner bushing 1 to reduce the friction between the outer bushing 2 and the inner bushing 1 and facilitate the relative rotation between the two.

[0024] The inner sleeve 1 has a first top surface 11 and a first bottom surface 12. In this embodiment, the first top surface 11 and the first bottom surface 12 are parallel to each other, and the center of the inner sleeve 1 defines an axis C1, The axis C1 is perpendicular to the top surface 11 and the bottom surface 12 at the same time.

[0025] On the other hand, a first slanted hole 13 is integrally provided in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com